Method of distilling liquid containing easily polymerizable compound

A distillation method and compound technology, applied in the field of distillation, can solve problems such as unfavorable economy, and achieve the effect of inhibiting polymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

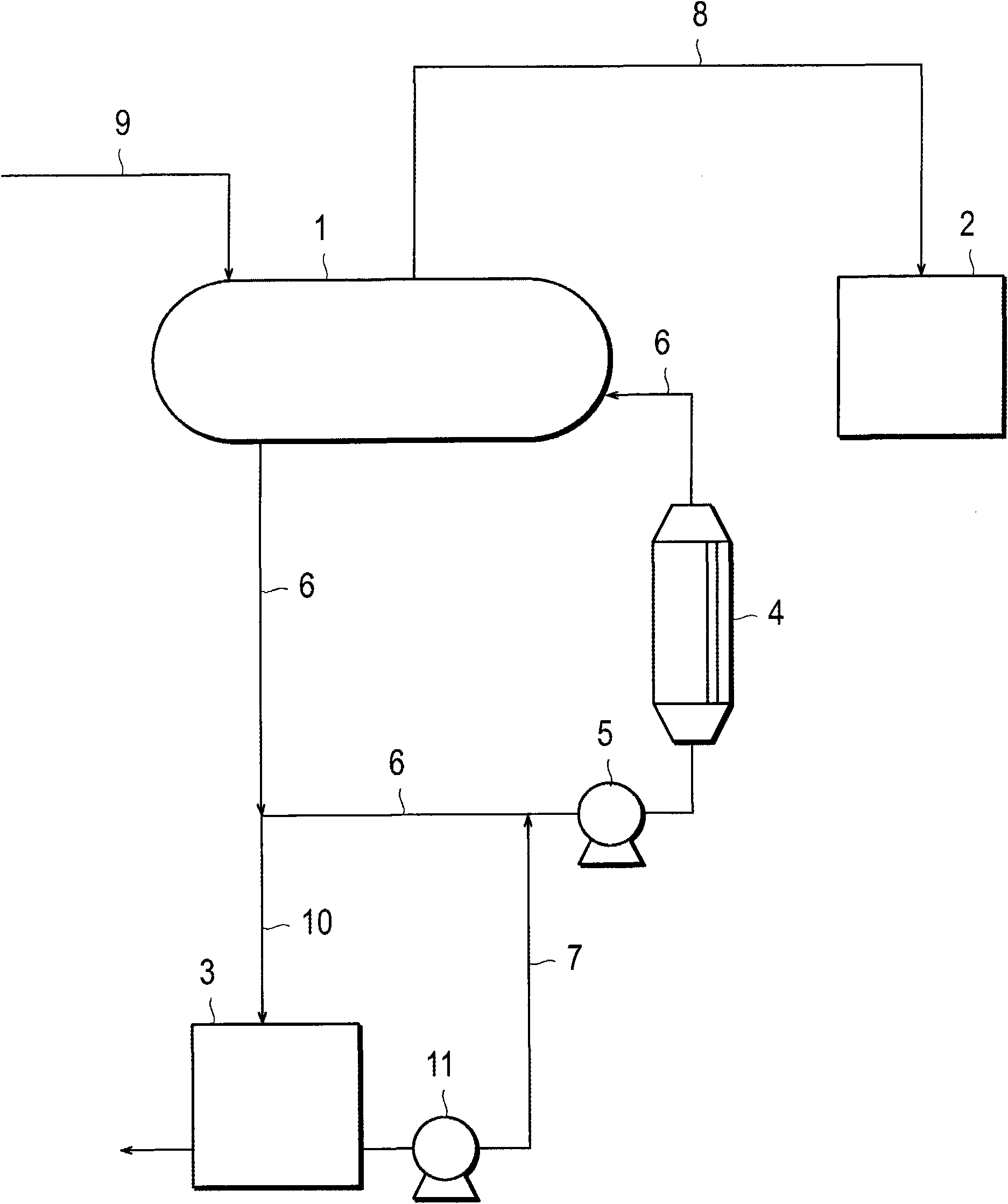

Method used

Image

Examples

Embodiment

[0057] Hereinafter, the present invention will be described in more detail by way of production examples, examples and comparative examples, but the present invention is not limited to these examples.

manufacture example

[0059] A distillation device made of SUS316 with a capacity of 2000L (simple distillation form. A multi-tube reboiler is set as a heating source, and a circulation pump is used for forced circulation.) is evacuated until the internal pressure reaches 5.33hPa, and then 1150kg (93.5% by mass) is fed ) a liquid containing hydroxyethyl methacrylate (hereinafter referred to as "HEMA") obtained from the reaction of methacrylic acid and ethylene oxide, and 0.12kg of p-methoxyphenol and 0.20kg of phenothiazine as polymerization inhibitors , steam was passed into the reboiler, and the distillation of the above-mentioned HEMA-containing liquid was started.

[0060] Distillation started when the liquid temperature reached 70°C, and was kept constant at 85°C thereafter. Distillation was terminated when the distilled amount reached 980 kg (85.2% by mass of the initial feed liquid), and 170 kg of distillation tower bottom liquid was obtained. Thereafter, the entire amount of the obtained d...

Embodiment 1

[0062] (first distillation)

[0063] In the same distillation apparatus as in the production example, feed 1150 kg of HEMA-containing liquid obtained by the reaction of methacrylic acid and ethylene oxide and 0.12 kg of p-methoxyphenol and 0.20 kg of phenothiene as a polymerization inhibitor. Zinc, start distillation.

[0064] From the moment when the amount of distillate reached 810 kg (70.4% by mass of the initial feed liquid), 62 kg (5.4% by mass of the initial feed liquid) of the distillation bottom liquid obtained in the production example was supplied to the distillation apparatus using a liquid delivery pump, Continue to distill. After 3.5 hours from the start of distillation, distillation was stopped when the amount of distillate reached 1100 kg (95.7% by mass of the initial feed liquid).

[0065] After the distillation was completed, 112 kg of residual tower bottom liquid remaining in the distillation apparatus was transferred to the same waste oil storage tank as i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com