A kind of preparation method of refined asphalt

A technology for refining asphalt and asphalt, which is applied in the direction of processing tar asphalt/petroleum asphalt/natural asphalt by selective extraction, and processing tar asphalt/petroleum asphalt/natural asphalt by chemical methods, which can solve the problem of long-term stable production of production equipment and very Difficult industrial long-term stable production, unsuitable for industrial production processes, etc., to achieve the effect of avoiding coking and deposition, low ash content, and similar polymerization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

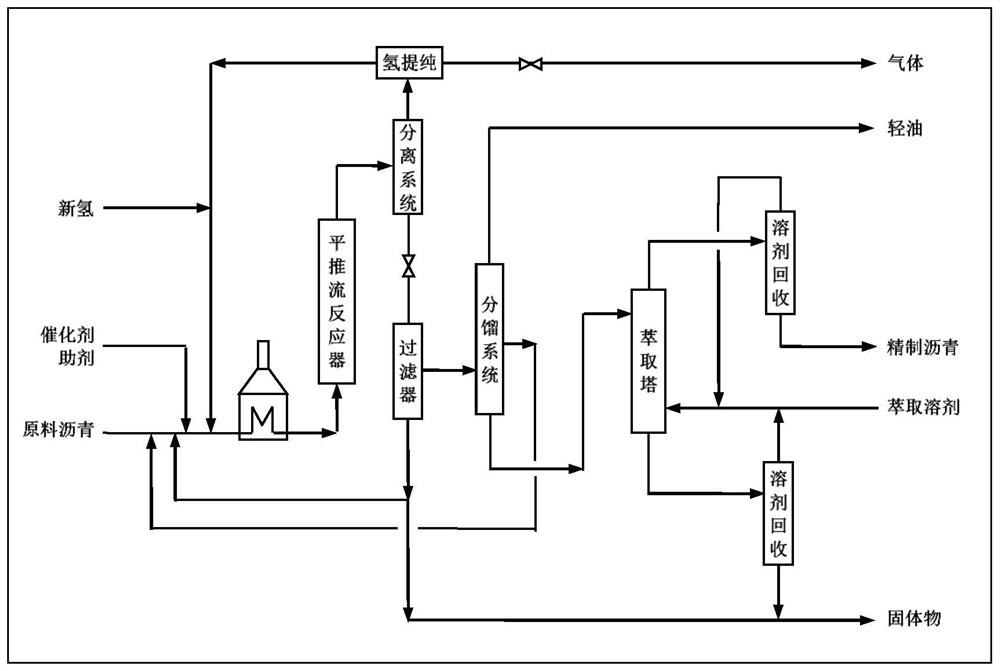

Method used

Image

Examples

Embodiment 1-4

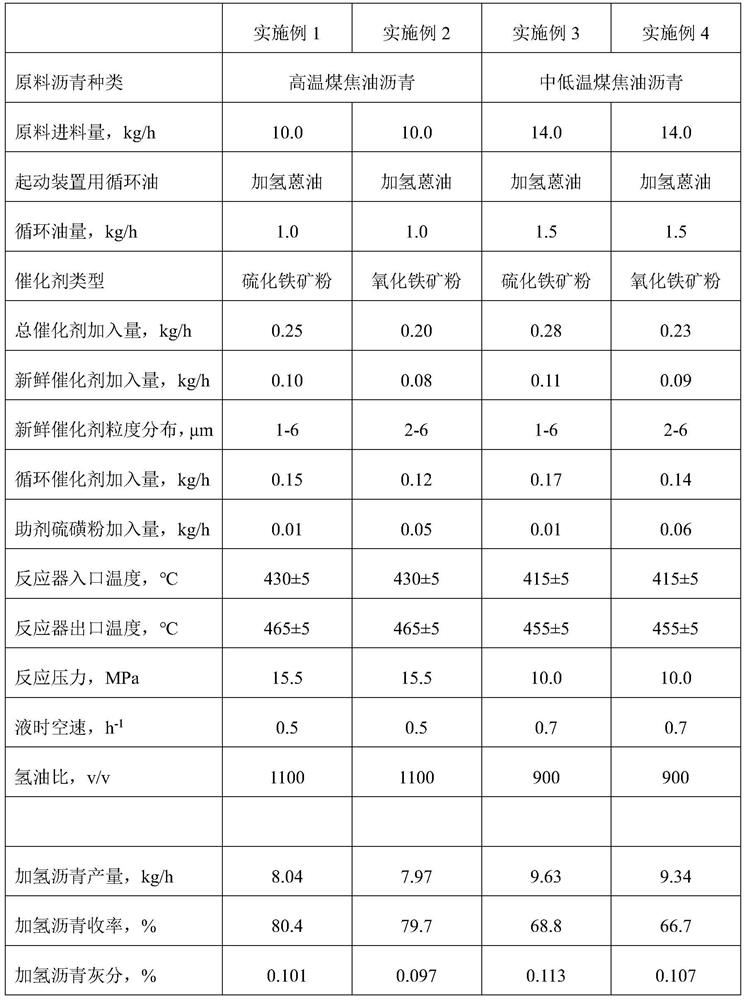

[0068] Using a high-temperature coal tar pitch and a medium-low temperature coal tar pitch as raw materials (the composition and properties of the raw material pitch are listed in Table 1), hydrogenation tests were carried out on a continuous hydrogenation test device to obtain hydrogenated pitch products. There are two upflow plug-flow reactors connected in series. The hydrogenation conditions and test results are listed in Table 2.

[0069] Table 1 Composition and properties of coal tar pitch

[0070] Type of asphalt High temperature coal tar pitch Medium and low temperature coal tar pitch Density (20℃), kg / m 3

1263.9 1047.9 Softening point, °C 76 49 Ash, wt% 0.185 0.132 Family composition, % saturated hydrocarbon 1.68 16.39 Aromatics 30.21 19.28 Colloid + asphaltenes 68.11 64.33 total 100.00 100.00 Elemental analysis,% H 4.82 8.81 C 91.95 85.08 N 1.08 0.65 S 0.59 0.44...

Embodiment 5-10

[0075]The solvent extraction test was carried out on a set of continuous extraction experimental equipment. The inner diameter of the extraction tower was 50mm, and the height of the extraction tower was 3m. It was divided into three parts: the upper settling section, the extraction section, and the lower settling section. (the lower end of the upper settling section) enters, and the solvent enters from the lower part of the extraction tower (the upper end of the lower settling section). The extract phase flows out from the top of the extraction tower to separate the solvent to obtain refined asphalt and solvent, wherein the refined asphalt is used as a product, and the solvent is recycled; the raffinate phase flows out from the bottom of the extraction tower to separate the solvent to obtain solids and solvents, of which the solids are used as by-products , solvent recycling. The temperature of the extraction tower increases gradually from bottom to top.

[0076] The hydroge...

Embodiment 11

[0081] The refined pitch prepared according to the above method has the advantages of narrow fraction, low sulfur content, low ash content, low quinoline insoluble content, etc., and is a high-quality raw material for preparing carbon materials.

[0082] Using the refined asphalt prepared in Example 6 above as a raw material, a polymerization test was carried out in a polymerization kettle with a capacity of 5 liters, automatic control of an electric heater, and an anchor type electric stirrer. The test process is as follows: weigh the heated and melted refined asphalt raw materials into the polymerization kettle, seal the polymerization kettle, start the agitator, and turn on the electric heater in sequence. The gas is exported to the polymerization kettle, and after a certain period of constant temperature, the electric heater and the agitator are turned off in turn, and then the temperature is naturally lowered. After polymerization, a mesophase pitch with excellent perform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com