Energy-saving and environment-friendly expanded ammonium nitrate explosive

An energy-saving and environmental protection technology for expanded ammonium nitrate explosive, which is applied in the directions of explosives, chemical industry, sustainable manufacturing/processing, etc. The problems of low density of ammonium explosives can reduce the direct processing cost of explosives, improve the level of safety production and explosives quality, and improve the level of environmental protection and energy saving and consumption reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

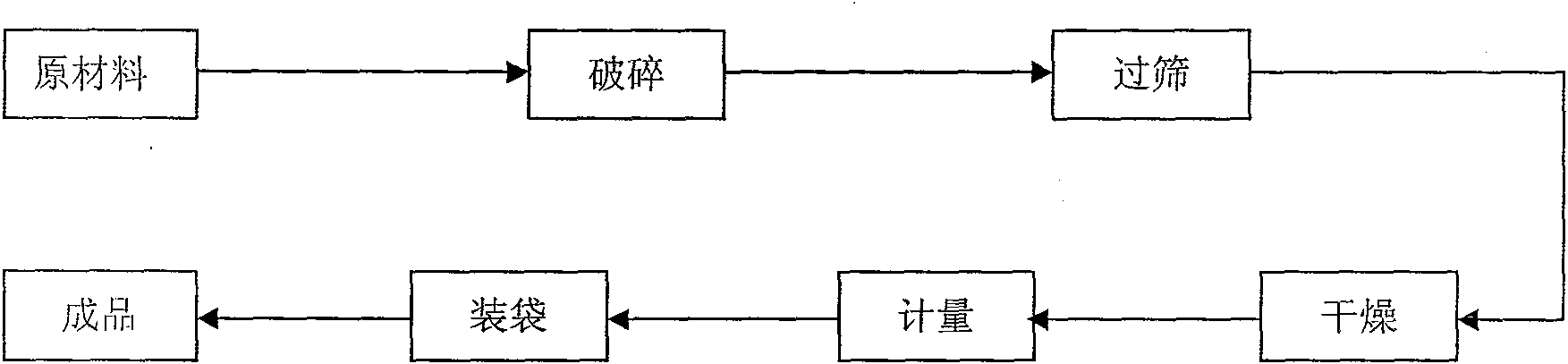

[0039]The present invention is further described below in conjunction with embodiment. Configure straw powder first, choose straw powder with no carbonization, no mildew, and no impurities as the raw material, and the moisture content must be ≤15% before drying. First of all, remove the sundries from the purchased raw materials and put them on the cement floor to spread out to dry, then crush them with a crusher, remove metal and other impurities through a vibrating screen, and then dry them continuously with a drying fan, (note that the feeding should be uniform, control Adjust the temperature of the combustion furnace so that the outlet temperature of the flame arrester is within 200°C to prevent carbonization), slowly add the dried woody material from the cyclone separator into the pulverizer, and carry out quality inspection when the pulverized woody material is cooled to below 40°C. The moisture content of the processed straw powder is ≤2%; the fineness requirement is tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com