Method for preparing vanadic oxide film growing along c-axis

A technology of vanadium pentoxide and oriented growth, which is applied in the field of preparing vanadium pentoxide films grown along the c-axis, can solve the problems of poor film growth orientation, complex equipment and processes, etc., and achieve high strength, simple process, and easy preparation low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

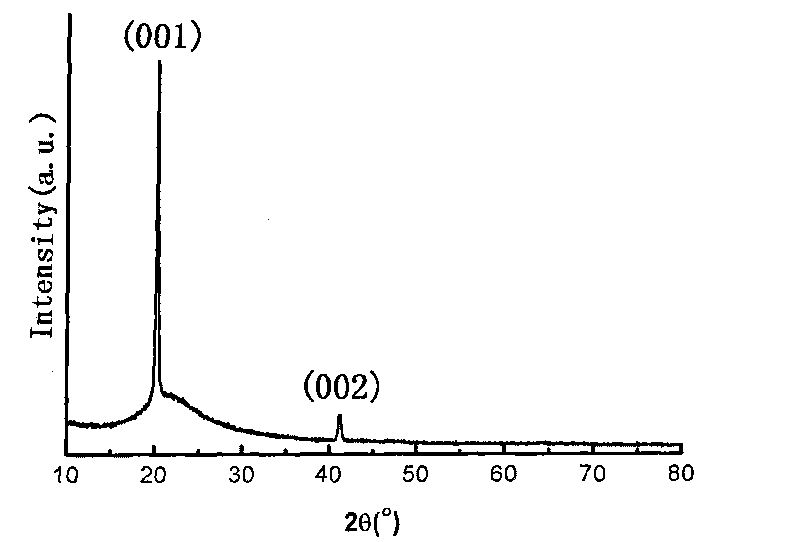

Embodiment 1

[0024] ① Take 1.33 grams of vanadyl diacetylacetonate, put it into 40 ml of absolute ethanol, stir it magnetically for 4 hours, let it stand for 15 days to age it, and form a vanadyl diacetylacetonate sol with a concentration of 0.125 mol / L;

[0025] ②The borosilicate glass is cleaned with detergent, deionized water, absolute ethanol, and acetone in sequence, assisted by ultrasonic cleaning, and then dried with hot air, and a silicon dioxide barrier layer is pre-coated on it.

[0026] ③Immerse borosilicate glass coated with amorphous silicon dioxide in vanadyl diacetylacetonate sol, pull it out at a constant speed of 5 cm / min, and dry it in an oven at 80°C to form vanadyl diacetylacetonate Gel film, and then dip the dried substrate coated with vanadyl diacetylacetonate gel film in the vanadyl diacetylacetonate sol, pull it out at a constant speed of 5 cm / min, and put it in an oven at 80 ° C Keep it in the middle for 10-20 minutes to dry, and then pull the coating film 15 times...

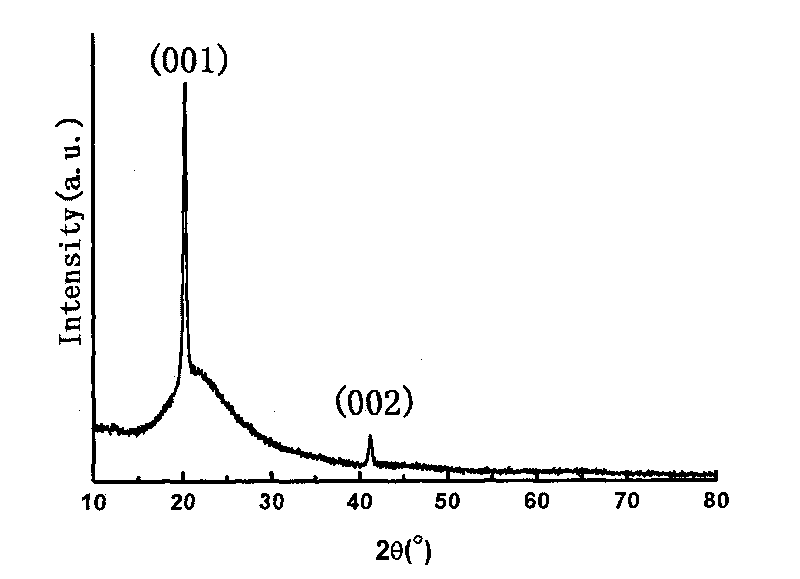

Embodiment 2

[0030] The steps are as in Example 1, wherein the sol concentration of vanadyl diacetylacetonate is adjusted to 0.1 mol / L. Repeatedly pulling the coating film 15 times in this way, the thickness of the obtained thin film sample is relatively small, and the thickness of the formed film is about 100nm, but still maintains the growth characteristics along the c-axis orientation.

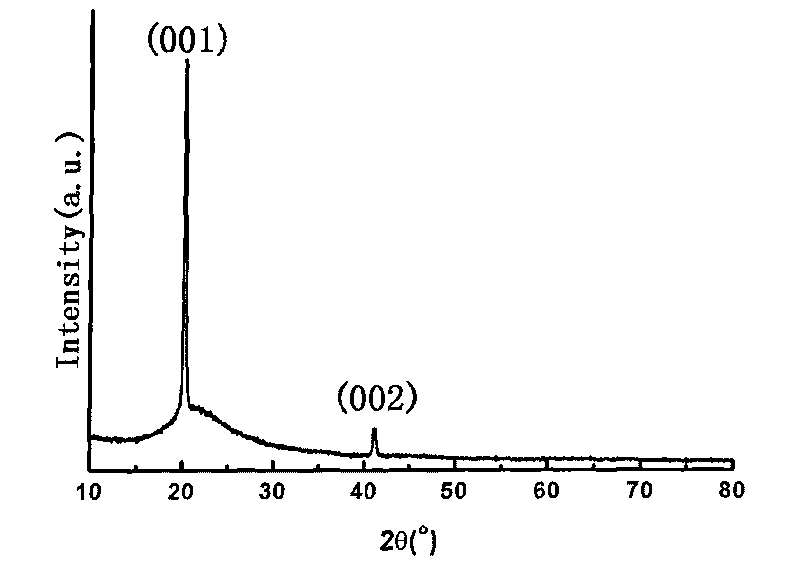

Embodiment 3

[0032] The steps are as in Example 1, wherein the sol concentration of vanadyl diacetylacetonate is adjusted to 0.7 mol / L. Repeatedly pulling the coating film 15 times in this way, the thickness of the formed film is about 300nm; but the film thickness is not very uniform, the crystallinity becomes better, and it grows along the c-axis orientation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com