High-temperature superconductive magnet system for magnetically confined plasma propeller

A high-temperature superconducting and plasma technology, applied in the directions of plasma, superconducting magnets/coils, magnetic objects, etc., can solve the problems of high operation cost, cumbersome operation, complex structure of superconducting magnets, etc., and achieve high-cost operation. , high magnetic field, eliminating the effect of low temperature system and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

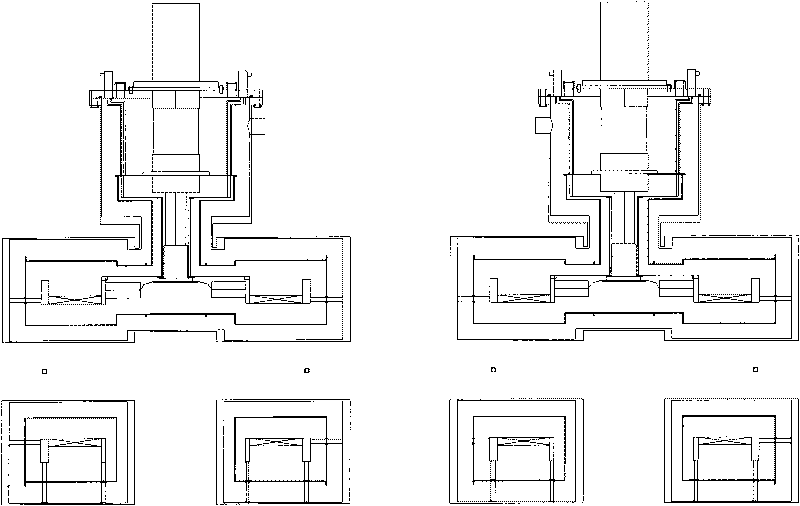

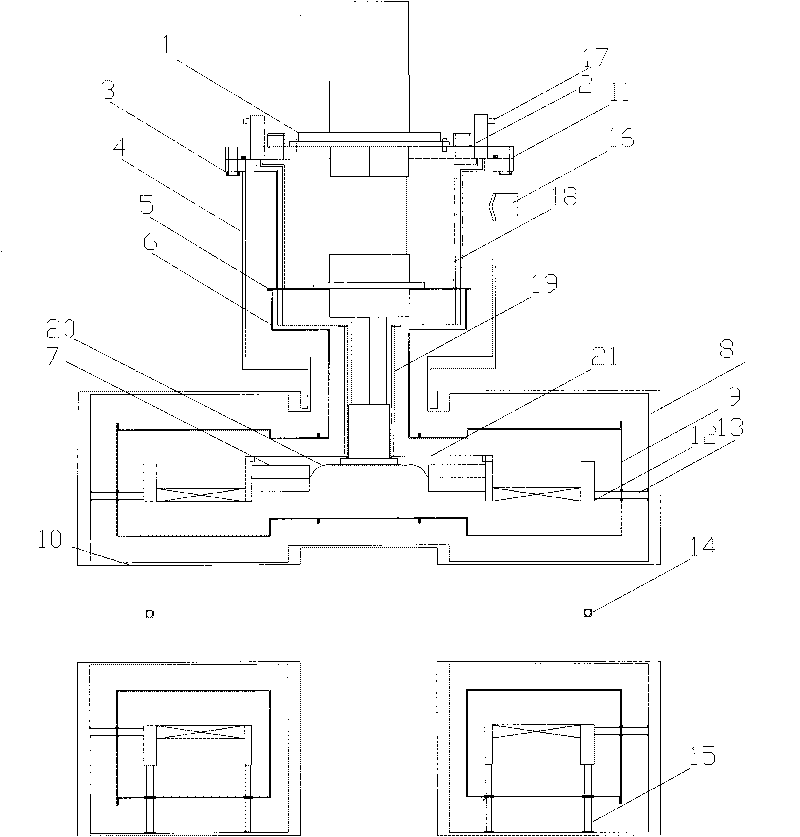

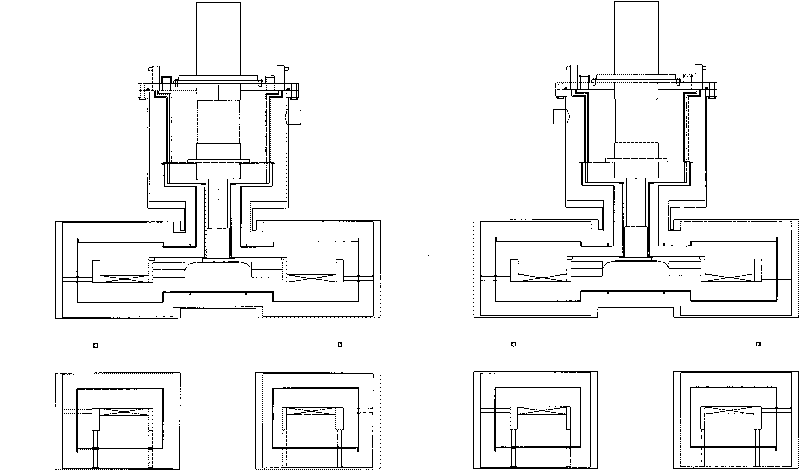

[0022] see figure 1 , 2 :

[0023] The high temperature superconducting magnet system of the magnetic confinement plasma thruster includes two magnetic mirror units with the same structure. In the description of one of the magnetic mirror units, it includes a Dewar cylinder 4, and the center of the annular cylinder is a concentric room temperature hole 10, and a copper cold shield 6 in the shape of a cylinder is installed in the Dewar cylinder 4. A refrigerator 1 is installed on the upper cover flange 11 . An epoxy fiberglass support rod 13 is installed between the end cover 8 of the Dewar cylinder on which the superconducting magnet is placed and the inner cold screen cover 9 , and the left end of the support rod 13 is connected to the superconducting magnet 12 . Epoxy fiberglass support rods 14 and 15 are installed between the Dewar cylinder and the superconducting magnet. The epoxy fiberglass support rod 14 is used for front and rear positioning, and the epoxy fiberglass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com