Method for desulfurizing and denitrating boiler gas simultaneously by using active carbon under microwave radiation

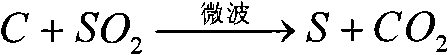

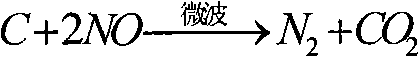

A technology for desulfurization, denitrification, and boiler flue gas is applied in the field of flue gas purification, which can solve the problems of high price of vanadium-based catalysts, difficult to popularize and use, and high operating costs, and achieve the effects of easy implementation, high recovery rate and low removal cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Preparation of activated carbon particles containing CuCl catalyst: a. The activated carbon particles with a particle size of 1-2 mm are fully cleaned with deionized water to remove surface impurities, and then fully soaked in deionized water for 6 hours to remove impurity ions adsorbed by activated carbon; b. Activated carbon particles are dried in an oven at 120°C to constant weight to obtain base carbon; c. Weigh 10kg CuCl, 490kg dilute HCl, the concentration of dilute hydrochloric acid is 5-10%, prepare a solution containing catalyst, and then add 1 cubic meter of activated carbon The particles were soaked in the above solution for 10 hours; d. The soaked activated carbon particles were repeatedly washed with deionized water until the eluate was neutral, and dried in an oven at 120°C to constant weight to obtain activated carbon particles containing catalyst.

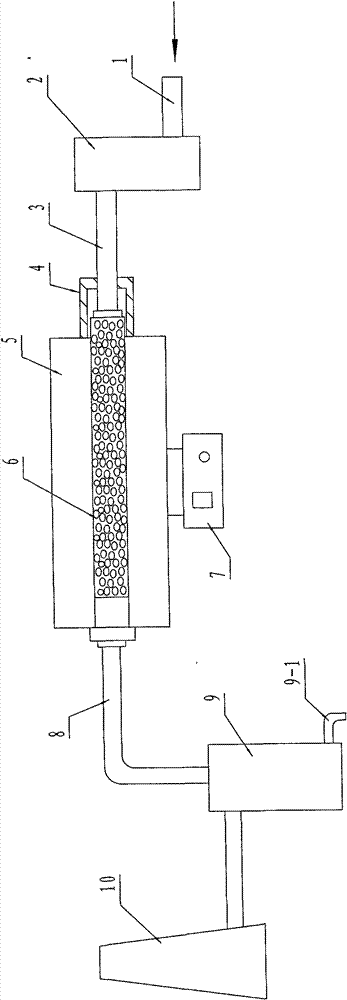

[0023](2) Flue gas desulfurization and denitrification: put the above-mentioned activated carbon partic...

Embodiment 2

[0026] (1) Preparation of activated carbon particles containing CuCl catalyst: a. Fully wash the activated carbon particles with deionized water to remove surface impurities, and then fully soak them in deionized water for 12 hours to remove impurity ions adsorbed by activated carbon; b. Put the activated carbon particles in an oven at 120 ° C Dry to constant weight to obtain base carbon; c. Weigh 30kg CuCl and 270kg dilute HCl to prepare a solution containing the catalyst, and then soak 1 cubic meter of activated carbon particles in the above solution for 2 hours; d. Repeatedly wash and soak with deionized water The activated carbon granules were dried in an oven at 100°C until the eluate was neutral, and the activated carbon granules containing the catalyst were obtained.

[0027] (2) Flue gas desulfurization and denitrification: put the above-mentioned activated carbon particles containing catalyst into a quartz tube to make an activated carbon bed, place the activated carbo...

Embodiment 3

[0030] (1) Preparation of activated carbon particles containing CuCl catalyst: a. Fully wash the activated carbon particles with deionized water to remove surface impurities, and then fully soak them in deionized water for 8 hours to remove impurity ions adsorbed by activated carbon; b. Put the activated carbon particles in an oven at 120 ° C Dry to constant weight to obtain base carbon; c. Weigh 20kg CuCl and 380kg dilute HCl to prepare a solution containing catalyst, and then soak 1 cubic meter of activated carbon particles in the above solution for 8 hours; d. Repeatedly wash and soak with deionized water Activated carbon granules until the eluate is neutral, and dried in an oven at 140°C to constant weight to obtain activated carbon granules containing catalyst.

[0031] (2) Flue gas desulfurization and denitrification: put the above-mentioned activated carbon particles containing catalyst into a quartz tube to make an activated carbon bed, place the activated carbon bed in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com