Water recycling device in artificial wetland organic industrial water with high concentration

A constructed wetland, high-concentration technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, sterilization/microdynamic water/sewage treatment, etc., can solve the problem of backward treatment technology, low reuse rate, High operating costs and other issues, to achieve the effect of low investment, small footprint, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

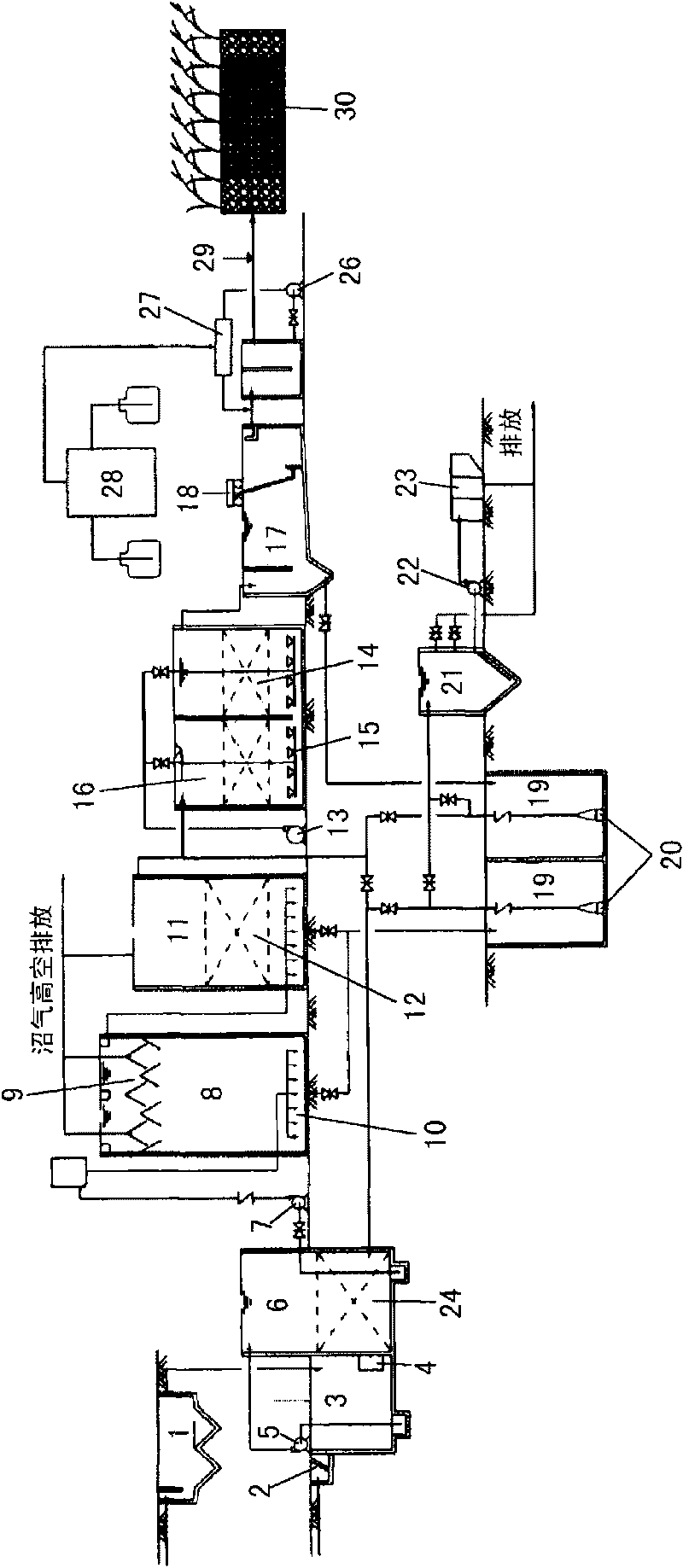

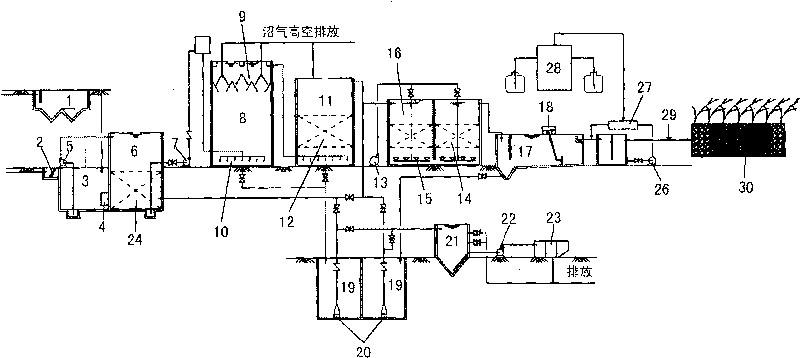

[0021] A specific example is as follows:

[0022] The water body is designed as an industrial water plant, the influent organic pollutant concentration is 6000mg / L, the designed effluent water quality is 20mg / L, and the designed flow rate is 400m 3 / d The removal efficiency of organic matter in each process stage is respectively, the removal rate of the neutralization adjustment tank is 25%, and the effluent water quality is 4500mg / L. The removal rate of organic matter in the hydrolysis regulating tank is 30%, and the effluent water quality index is 3150mg / L. The removal rate of organic matter in the anaerobic tank is 80%, and the effluent quality is 630mg / L. The removal rate of organic matter in the contact oxidation tank is 60%, and the effluent index is 50mg / L. The removal rate of organic matter in the sedimentation tank is 60%, and the effluent index is 20mg / L. The organic matter removal rate of the constructed wetland is 80%, and the effluent index is 4mg / L.

[0023] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com