Method for manufacturing photonic crystal optical fiber coupler

A technology of photonic crystal fiber and manufacturing method, which is applied in the coupling of optical waveguides, etc., can solve the problems of inconvenient operation and unsatisfactory coupling ratio, and achieve the effects of small coupling length, stable performance, and suitable for miniaturization and integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Further illustrate the present invention below in conjunction with accompanying drawing and embodiment.

[0023] Take making a 2×2 coupler as an example.

[0024] A method for manufacturing a photonic crystal fiber coupler, comprising the following steps:

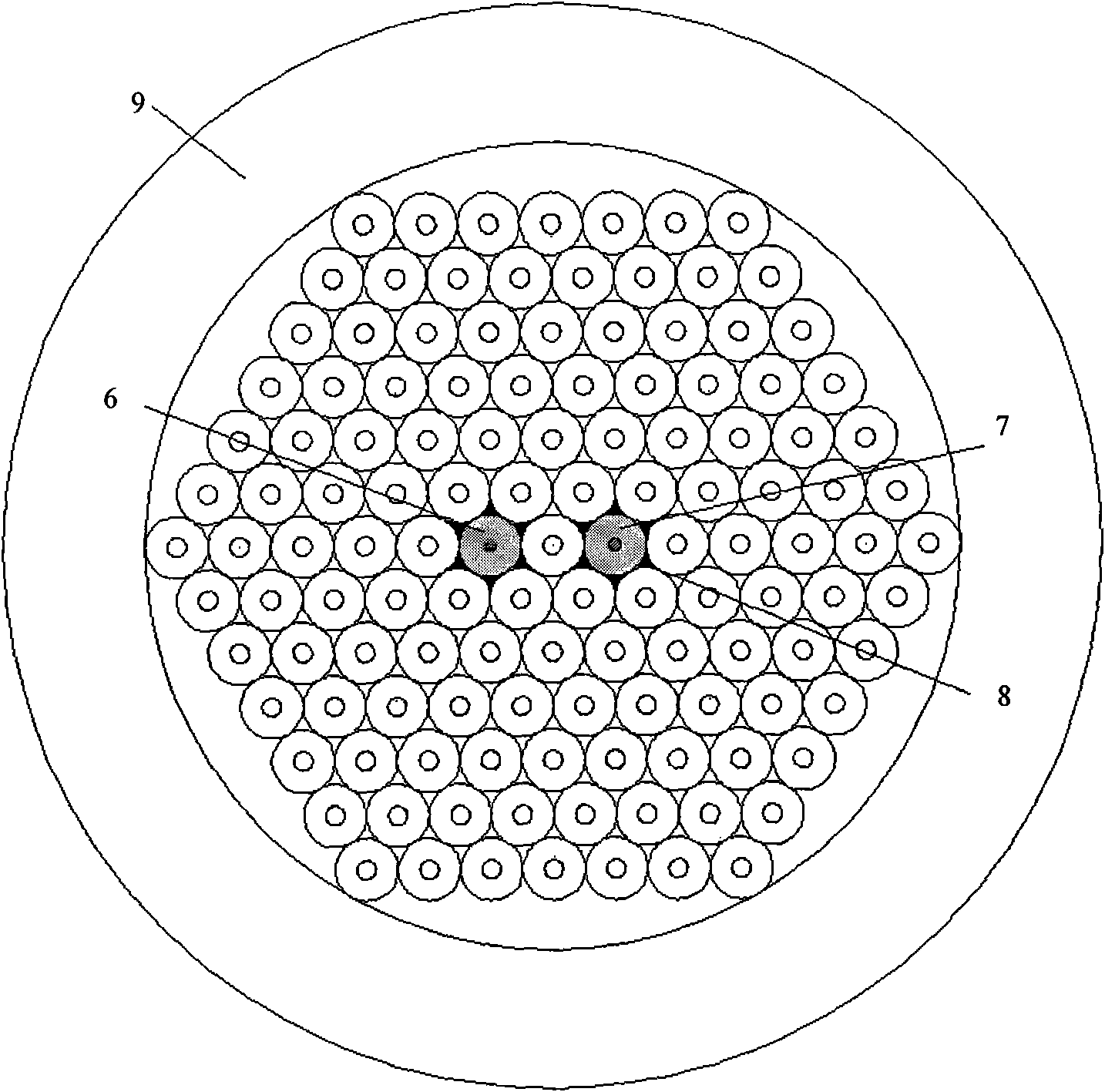

[0025] 1) Determine the number and position of defects introduced into the photonic crystal fiber according to the beam splitting ratio of the coupler 2×2, and determine the length and number of photonic crystal fiber silicon tubes required according to the size of the coupler; this example introduces defects in the photonic crystal fiber The number of silicon tubes is 2, and the position is symmetrical with respect to the central silicon tube. The length of the photonic crystal fiber silicon tube is 1.5mm×ratio before and after the taper, and the number of silicon tubes is stacked up to six layers.

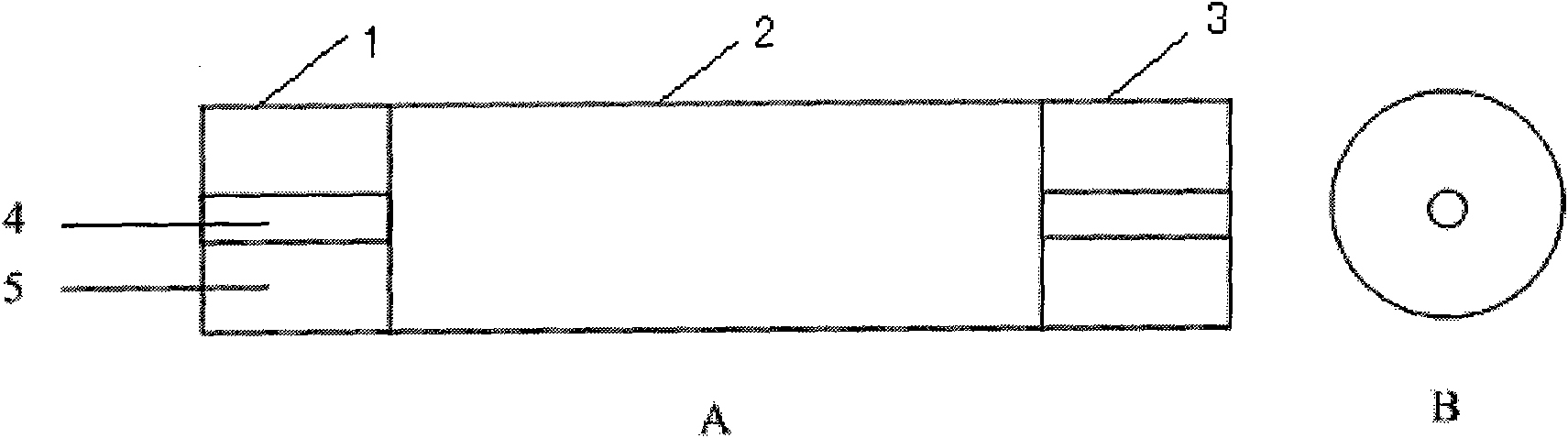

[0026] 2) making a single-mode optical fiber preform (such as figure 1 shown), the length and diameter of the middl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com