Sandwich layer slow-release birth control material

A sandwich layer, slow-release technology, applied in the field of medical materials, can solve the problems of breakage and falling off of IUDs, serious copper ion release phenomenon, uncontrollable copper ion release speed, etc., and achieve the effect of controllable release speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0031] Upper surface layer: Weigh 5g polyvinyl alcohol (referred to as PVA, the same below), add 2.14g SiO 2 , Add distilled water to 100g, stir at 90°C for 1 hour to obtain uniform PVA / SiO 2 The solution was cast into a film on a smooth and flat 20cm×30cm glass plate.

[0032] Intermediate layer: Weigh 5g PVA, add 2.14g SiO 2 , Add distilled water to 100g, stir at 90°C for 1 hour to obtain uniform PVA / SiO 2 The solution was cooled to 40° C., 4.76 g of copper chloride was added, and stirred for 0.5 hours to obtain a uniform membrane liquid. Cast film on the above-mentioned dried film.

[0033] Lower surface layer: prepare the same PVA / SiO according to the method of preparing the upper surface layer 2 Solution. Cast film on the above-mentioned dried film.

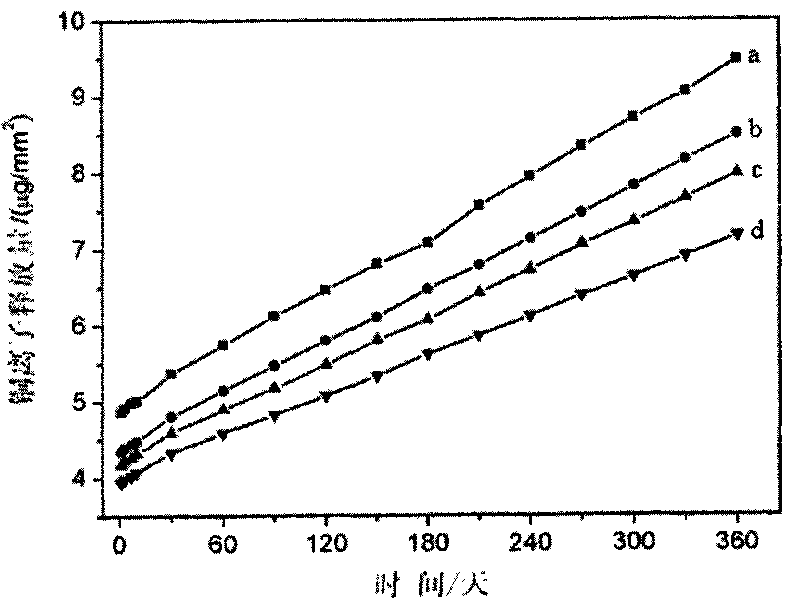

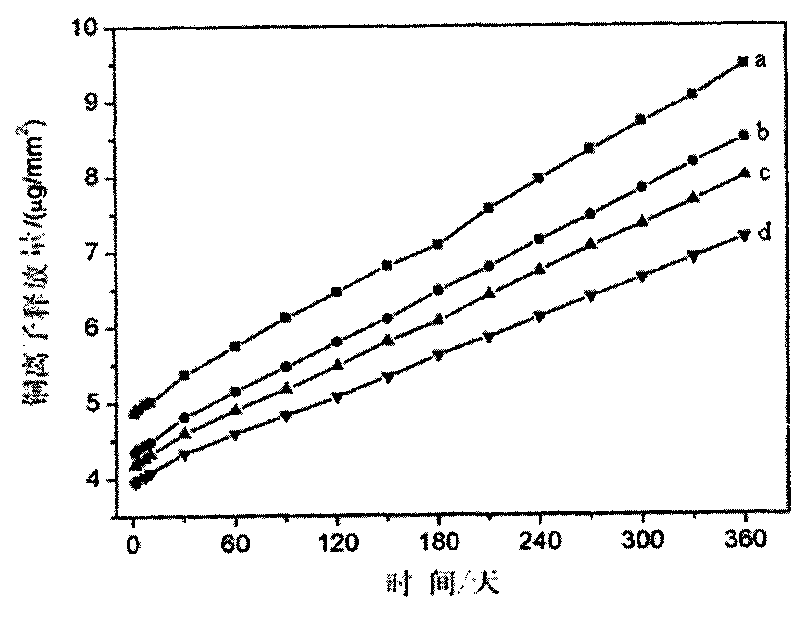

[0034] After drying, take it off and immerse it in a simulated human body fluid to measure the release of copper ions. Such as figure 1 Curve a in the middle, namely 30% SiO 2 / PVA, 30% SiO 2 / 40%CuCl 2 / PVA, 30% SiO 2 / PVA.

example 2

[0036] Upper surface layer: Weigh 5g PVA and add 2.14g SiO 2 , Add distilled water to 100g, stir at 90°C for 1 hour to obtain uniform PVA / SiO 2 The solution was cast into a film on a smooth and flat 20cm×30cm glass plate.

[0037] Intermediate layer: Weigh 5g PVA and add 3.33g SiO 2 , Add distilled water to 100g, stir at 90°C for 1 hour to obtain uniform PVA / SiO 2 The solution was cooled to 40° C., 5.55 g of copper chloride was added, and stirred for 0.5 hours to obtain a uniform membrane liquid. Cast film on the above-mentioned dried film.

[0038] Lower surface layer: prepare the same PVA / SiO according to the method of preparing the upper surface layer 2 Solution. Cast film on the above-mentioned dried film.

[0039] After drying, take it off and immerse it in a simulated human body fluid to measure the release of copper ions. Such as figure 1 Curve b in the middle, which is 30% SiO 2 / PVA, 40% SiO 2 / 40%CuCl 2 / PVA, 30% SiO 2 / PVA. figure 1 The surface layer composition of mid...

example 3

[0041] Upper surface layer: Weigh 5g PVA, add 3.33g SiO 2 , Add distilled water to 100g, stir at 90°C for 1 hour to obtain uniform PVA / SiO 2 The solution was cast into a film on a smooth and flat 20cm×30cm glass plate.

[0042] Intermediate layer: Weigh 5g PVA, add 2.14g SiO 2 , Add distilled water to 100g, stir at 90°C for 1 hour to obtain uniform PVA / SiO 2 The solution was cooled to 40° C., 4.76 g of copper chloride was added, and stirred for 0.5 hours to obtain a uniform membrane liquid. Cast film on the above-mentioned dried film.

[0043] Lower surface layer: prepare the same PVA / SiO according to the method of preparing the upper surface layer 2 Solution. Cast film on the above-mentioned dried film.

[0044] After drying, take it off and immerse it in a simulated human body fluid to measure the release of copper ions. Such as figure 1 Curve c in the middle, which is 40% SiO 2 / PVA, 30% SiO 2 / 40%CuCl 2 / PVA, 40% SiO 2 / PVA. figure 1 The composition of the middle layer of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com