Microbe transglutaminase modified soya flour-based wood adhesive and preparation method thereof

A technology of transglutaminase and wood adhesive, which is applied in the directions of starch adhesive, adhesive type, polymer adhesive additive, etc., can solve the problems of large energy consumption, high cost, environmental pollution, etc. Low cost, safe use, simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

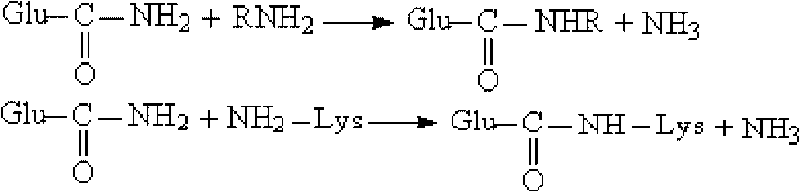

Method used

Image

Examples

specific Embodiment approach 1

[0008] Specific embodiment 1: The soybean flour-based wood adhesive modified by microbial transglutaminase in this embodiment consists of 400-500 parts by mass of water, 80-120 parts of low-temperature defatted soybean powder and 1.0-1.4 parts of microorganisms Made with transglutaminase; the particle size of low-temperature defatted soybean powder is less than 120 mesh; the activity of microbial transglutaminase is 100U / g.

[0009] In this embodiment, the protein content of the low-temperature defatted soybean flour is 52.0% to 54.0%.

specific Embodiment approach 2

[0010] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the soybean flour-based wood adhesive modified by microbial transglutaminase consists of 420-480 parts of water and 90-110 parts of low-temperature defatted soybeans in parts by mass. powder and 1.1 to 1.3 parts of microbial transglutaminase. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0011] Specific embodiment three: the difference between this embodiment and specific embodiment one is that the soybean flour-based wood adhesive modified by microbial transglutaminase is composed of 460 parts of water, 100 parts of low-temperature defatted soybean powder and 1.2 parts by mass. produced by microbial transglutaminase. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Tensile shear strength | aaaaa | aaaaa |

| Adhesive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com