Sewage treatment system

A technology of sewage treatment system and aeration system, which is applied in the field of new sewage treatment process system, can solve the problems of inability to maintain high concentration, limit biochemical reaction efficiency, and high operating energy consumption cost, achieve good effluent quality, reduce investment and operation Cost, efficient and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

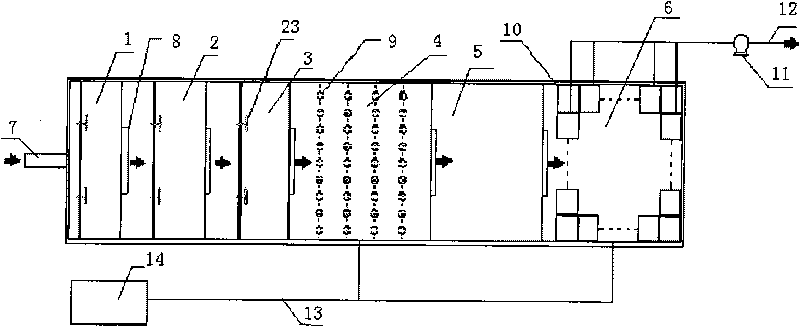

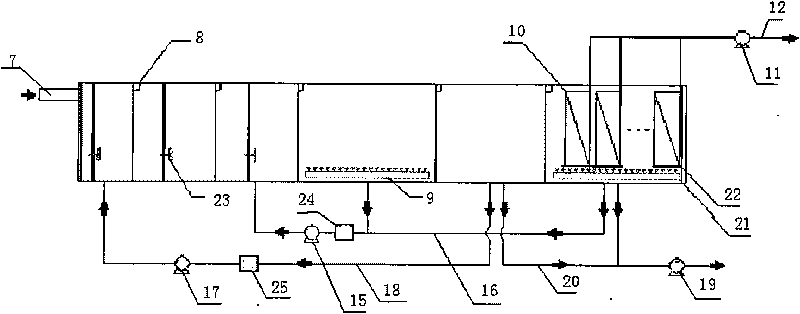

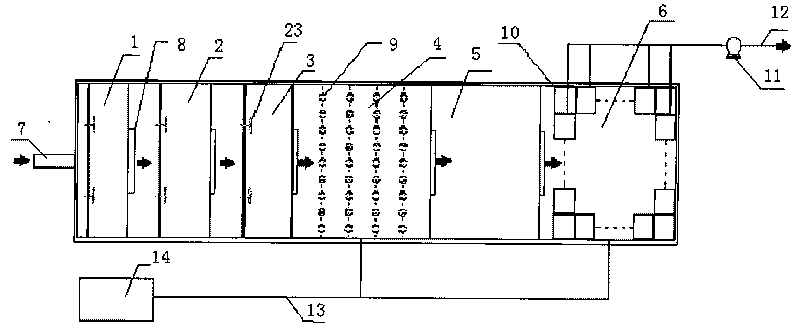

[0031] see figure 1 and figure 2, a sewage treatment system, comprising selection zone 1, anaerobic pool 2, anoxic pool 3, aerobic pool 4, sedimentation adjustment pool 5, aerobic membrane pool 6, water inlet 7, water outlet weir 8, aeration system 9 , membrane block 10, outlet pump 11, outlet pipe 12, air pipe 13, blower 14, mixed liquid return pump 15, mixed liquid return pipe 16, sludge return pump 17, sludge return pipe 18, excess sludge pump 19 , excess sludge pipe 20, aerobic membrane tank aeration system 21, membrane block backwashing device 22, plug flow agitator 23, mixed liquid backflow automatic control device 24, sludge backflow automatic control device 25; selection area 1, Anaerobic pool 2, anoxic pool 3, aerobic pool 4, sedimentation regulating pool 5, and aerobic membrane pool 6 are connected successively through the outlet weir 8; push flow is provided in selection area 1, anaerobic pool 2, and anoxic pool 3 Agitator 23; aerobic tank 4 and aeration system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com