Formulation and preparation method for low-temperature-resistant environment-friendly automobile non-freezing solution

An environmentally friendly, low-temperature-resistant technology, applied in the field of antifreeze, can solve the problems of easy precipitation, short service life, and explosion, and achieve the advantages of environmental protection, superior resistance to hard water, and excellent low-temperature resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

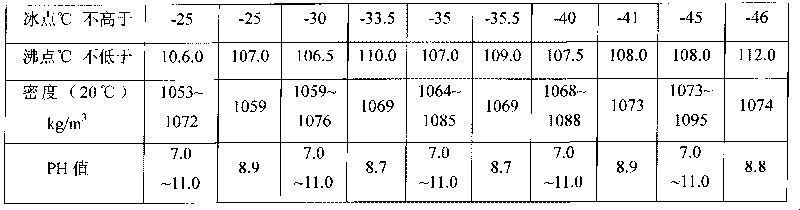

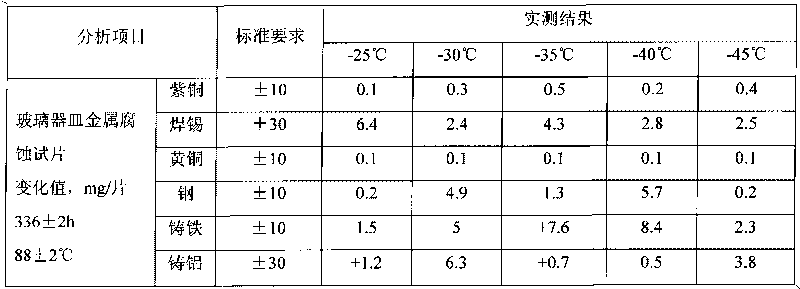

Embodiment 1

[0039] Prepare antifreeze in the following proportions:

[0040] Dimethyl sulfoxide 37%

[0041] Deionized Water 63%,

[0042] Taking the basic raw material as 100% mass basis, the weight percentages of other ingredients added are:

[0043] Triethanolamine 0.8%

[0044] Benzotriazole 0.1%

[0045] Sebacic acid 0.25%

[0046] Sodium 2-Mercaptobenzothiazole 0.08%

[0049] Sodium silicate 0.1%

[0050] Emulsified silicone oil defoamer 0.004%

[0051] Fluorescein 0.005%.

[0052] 1. Add 37 kg of dimethyl sulfoxide to reaction kettle A, followed by 0.8 kg of triethanolamine, 0.1 kg of benzotriazole, and 0.25 kg of sebacic acid, and stir thoroughly for 15 to 20 minutes until all are dissolved.

[0053] 2. In the reaction kettle B, add 63kg of deionized water, 0.08kg of sodium 2-mercaptobenzothiazole, 0.11kg of sodium hydroxide, and stir for 15 to 20 minutes, then add 0.1kg of sodium nitrate and 0.1kg of sodium si...

Embodiment 2

[0056] Prepare antifreeze in the following proportions:

[0057] Dimethyl sulfoxide 43.5%

[0058] Deionized water 56.5%

[0059] Taking the basic raw material as 100% mass basis, the weight percentages of other ingredients added are:

[0060] Triethanolamine 0.85%

[0061] Benzotriazole 0.11%

[0062] Sebacic acid 0.28%

[0063]Sodium 2-Mercaptobenzothiazole 0.09%

[0064] Sodium nitrate 0.11%

[0065] Sodium Hydroxide 0.12%

[0066] Sodium silicate 0.1%

[0067] Emulsified silicone oil defoamer 0.004%

[0068] Fluorescein 0.005%

[0069] The specific implementation steps are the same as in Example 1.

Embodiment 3

[0071] Prepare antifreeze in the following proportions:

[0072] Dimethyl sulfoxide 44%

[0073] Deionized water 56%

[0074] Taking the basic raw material as 100% mass basis, the weight percentages of other ingredients added are:

[0075] Triethanolamine 0.9%

[0076] Benzotriazole 0.12%

[0077] Sebacic acid 0.3%

[0078] Sodium 2-Mercaptobenzothiazole 0.1%

[0079] Sodium nitrate 0.11%

[0080] Sodium Hydroxide 0.13%

[0081] Sodium silicate 0.11%

[0082] Emulsified silicone oil defoamer 0.004%

[0083] Fluorescein 0.005%

[0084] The specific implementation steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com