New energy-saving process for preparing MTG (or DME) with rough (refined) methanol

A new process, methanol technology, applied in the field of crude methanol to MTG energy-saving new process, can solve the problems of repeated investment, high energy consumption, etc., achieve low energy consumption, reduce engineering investment, and realize the effect of comprehensive utilization of heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] specific implementation plan

[0028] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

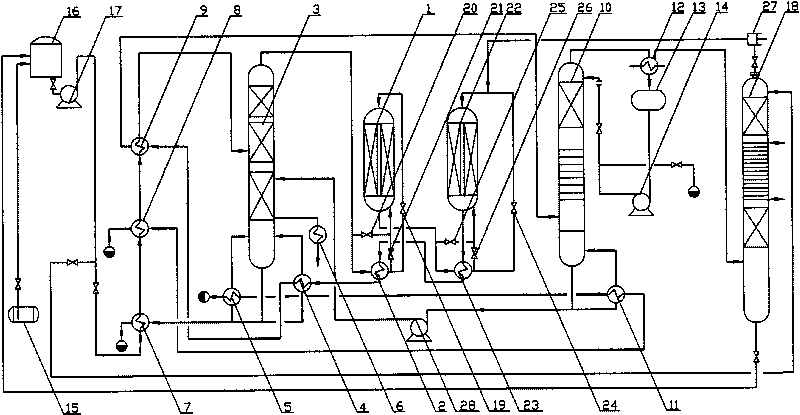

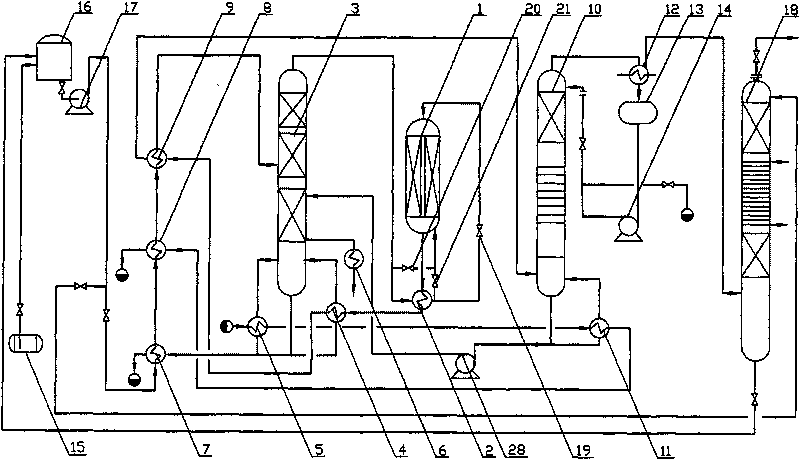

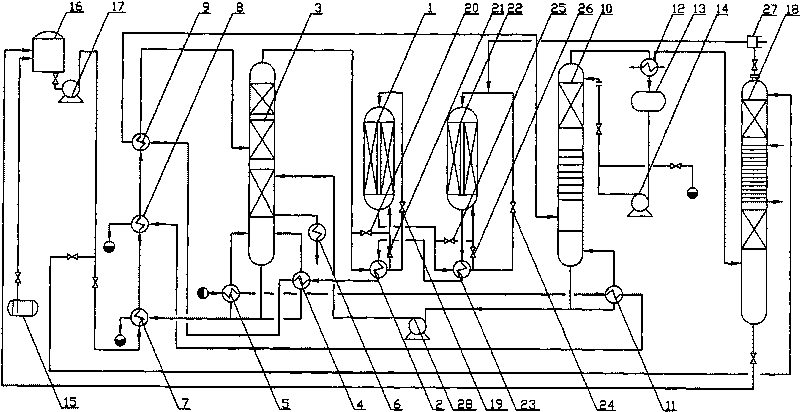

[0029] Option 1, a new process for methanol to produce dimethyl ether and dimethyl ether to regenerate gasoline, such as figure 1 As shown, has the following process:

[0030] a. Methanol transportation and waste heat recovery process;

[0031] b. Methanol separation and concentration process;

[0032] c, methanol dehydration reaction process;

[0033] d. DME (or methanol) conversion process to MTG;

[0034] e. Product distillation and separation process;

[0035] f. Exhaust gas washing and recovery process.

[0036] In step a of the process of the present invention, after the methanol is pressurized by the raw material pump 17, the waste heat heater 7, the second-stage waste heat heater 8, and the third-stage waste heat heater 9 are respectively used to recover residual liquid, steam condensed water and reacted ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com