Preparation method for spherical nanometre magnesium ferrite desulfurizer

A technology of magnesium ferrite and desulfurizer is applied in the preparation of nanometer flue gas desulfurizer and the field of preparation of nanometer magnesium ferrite desulfurizer to achieve good adsorption performance, good application value and application prospect, and the effect of broadening the synthesis method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

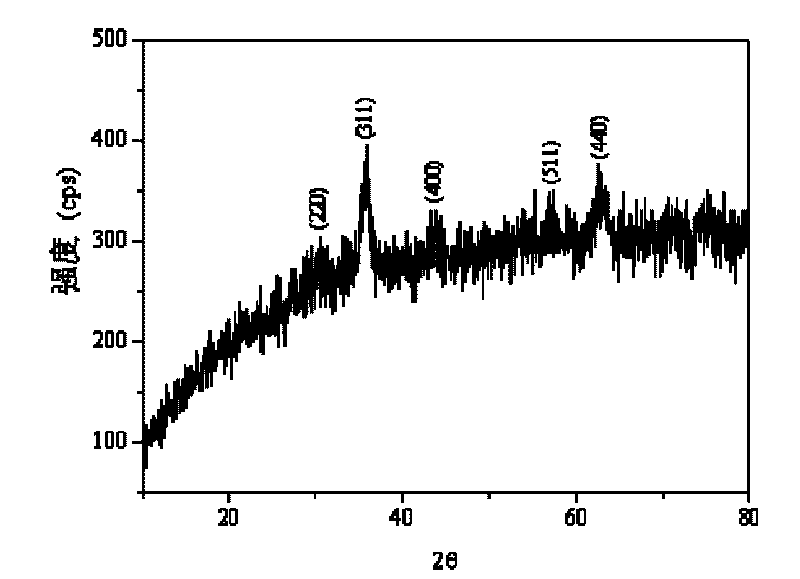

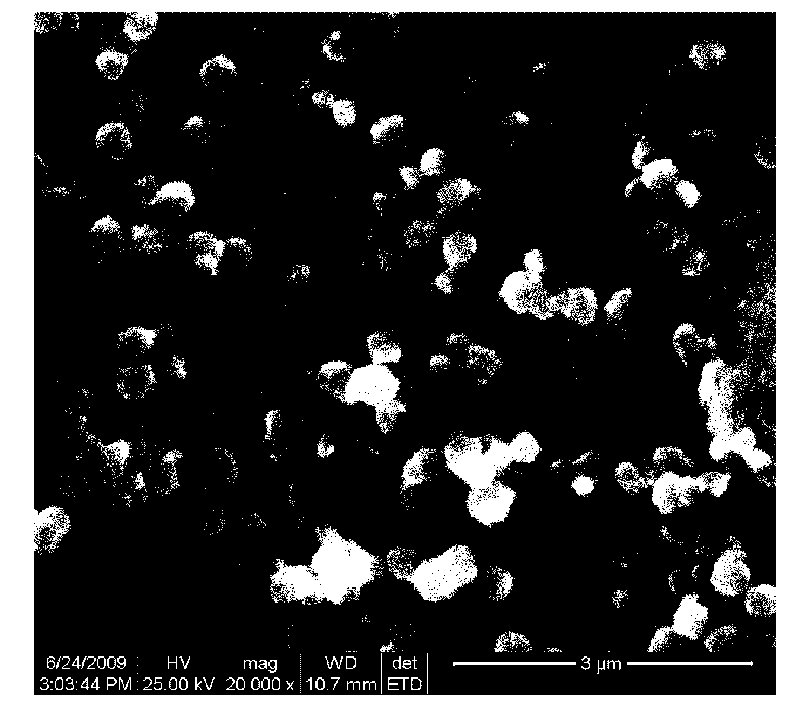

Embodiment 1

[0018] Weigh 0.808gFe(NO 3 ) 3 9H 2 O and 0.512gMg(NO 3 ) 2 ·6H 2 O was dissolved in 60ml of ethylene glycol, put into a constant temperature water bath magnetic stirring pot and stirred at room temperature until the solution was completely clear, and then 30mmolNH 4 Ac was added to the above solution, and the microemulsion obtained above was placed in an autoclave at 180° C. for 24 hours to crystallize. Wash the obtained sample with water / alcohol / separate, and dry overnight at 60°C in a vacuum oven to obtain MgFe 2 o 4 Nanosphere precursors. The dried sample was put into a muffle furnace, and the temperature was programmed from room temperature to 500 °C at a rate of 1 °C / min, and then calcined at 500 °C for 2 hours, and finally the spherical shape of MgFe was obtained. 2 o 4 Desulfurizer.

Embodiment 2

[0020] According to the preparation method of the present invention of embodiment 1, Fe(NO 3 ) 3 9H 2 O mass increased to 2.4g, Mg(NO 3 ) 2 ·6H 2 O mass increased to 1.5g, ethylene glycol volume increased to 180ml, NH 4 Ac increased to 90mmol, and crystallized at 200°C for 24h in the reactor to obtain spherical shape MgFe 2 o 4 Desulfurizer.

Embodiment 3

[0022] According to the preparation method of the present invention in Example 1, the volume of ethylene glycol is increased to 100ml, and the hydrothermal reaction is carried out at 200°C for 30h to obtain spherical shape MgFe 2 o 4 Desulfurizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com