Catalyst for selectively producing propene by methanol or dimethyl ether and preparation method thereof

A technology of dimethyl ether and selectivity, which is applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of low selectivity of single-pass propylene and achieve good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] According to the molar ratio of SiO 2 :Al 2 o 3 :P 2 o 5 :H 2 O: di-n-propylamine=1.0: 1.0: 1.0: 36: 1.2, dissolve 2.2 g of the raw material pseudo-boehmite in 15 mL of distilled water and 2.2 g of phosphoric acid mixture and stir at room temperature for 1 h, then add the raw material silica sol (mass fraction 20%) 2.3g, H-ZSM-51.5g and di-n-propylamine 1.2g, respectively stirred at room temperature for 1h. where n(SiO 2 ) / n(Al 2 o 3 )=1.0, n(P 2 o 5 ) / n(Al 2 o 3 )=1.0, n(di-n-propylamine) / n(Al 2 o 3 )=1.2, n(Al 2 o 3 ) / n(H 2 (0)=36.

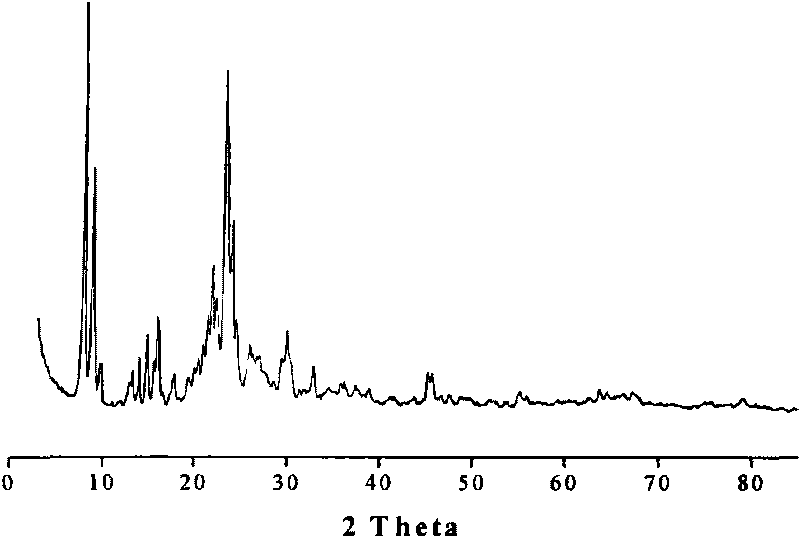

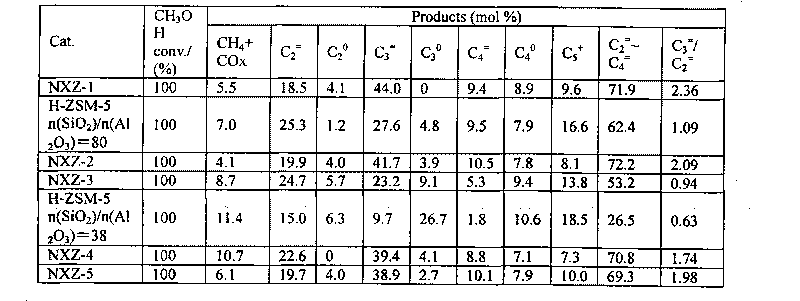

[0030] The mixture was charged into a polytetrafluoroethylene-lined crystallization kettle, and crystallized at 170°C and 200°C for 24h, respectively. The product was filtered, washed, dried at 120°C for 12 hours, heated to 600°C at 2°C / min, and calcined for 4 hours to obtain the catalyst NXZ-1. Wherein H-ZSM-5 mass fraction accounts for 40%, n(SiO 2 ) / n(Al 2o 3 )=80, its phase composition see figure 1 , where 2θ=8....

Embodiment 2

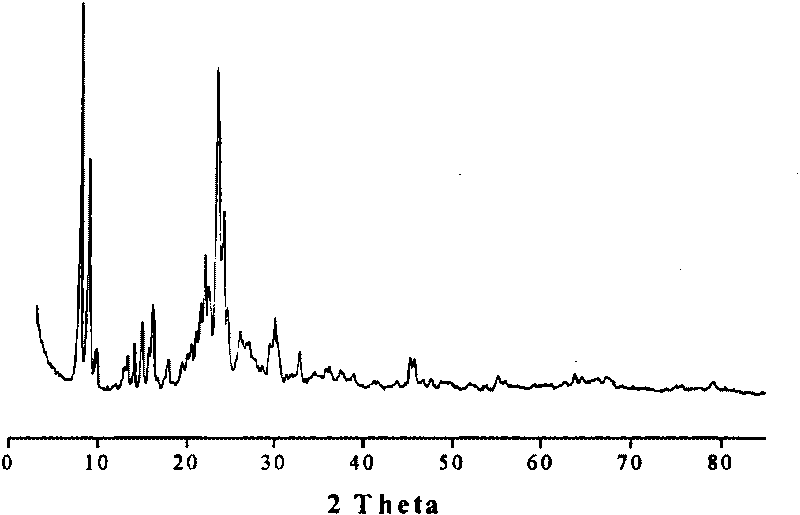

[0035] According to the preparation steps of Example 1, wherein n(SiO 2 ) / n(Al 2 o 3 )=1.0, n(P 2 o 5 ) / n(Al 2 o 3 )=1.0, n(diethylamine) / n(Al 2 o 3 )=1.2, n(Al 2 o 3 ) / n(H 2 O)=36, use n(SiO 2 ) / n(Al 2 o 3 )=80 of H-ZSM-53.0g to prepare catalyst NXZ-2. The mass fraction of H-ZSM-5 accounts for 58%. The activity results are shown in Table 1.

Embodiment 3

[0037] According to the preparation steps of Example 1, wherein n(SiO 2 ) / n(Al 2 o 3 )=38 of H-ZSM-51.5g to prepare catalyst NXZ-3. The mass fraction of H-ZSM-5 accounts for 70%. The activity results are shown in Table 1. As a comparison H-ZSM-5(n(SiO 2 ) / n(Al 2 o 3 )=38) the activity results are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com