Method for preparing lanthanum nickel oxide ceramic target

A technology of ceramic target and lanthanum nickelate, which is applied in the field of microelectronic material preparation, can solve the problems of ceramic target mixing, reduce the degree of decomposition and prevent decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The preparation method of the lanthanum nickelate ceramic target of the present invention comprises the following steps:

[0038] ①. Weigh an appropriate amount of lanthanum nitrate, nickel nitrate, and citric acid, so that the molar ratio is La 3+ : Ni 2+ :(C 6 h 8 o 7 ·H 2 (0)=1:1:5, miscible in 200ml deionized water, stirred with a magnetic stirrer and heated in a constant temperature water bath at 80°C for 2 hours to obtain a green transparent sol, and then place the sol in a constant temperature drying oven at 130°C for 10 hour, light brown xerogel was obtained, which was ground into powder;

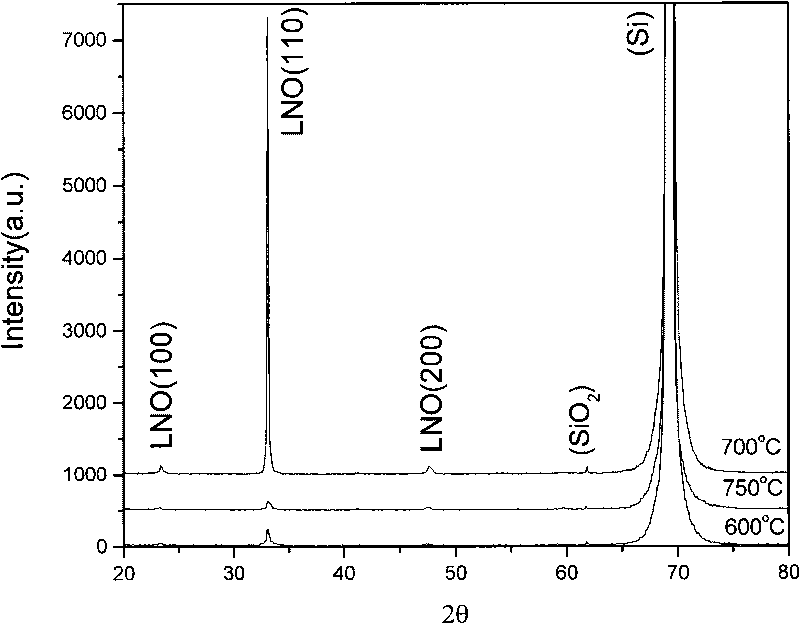

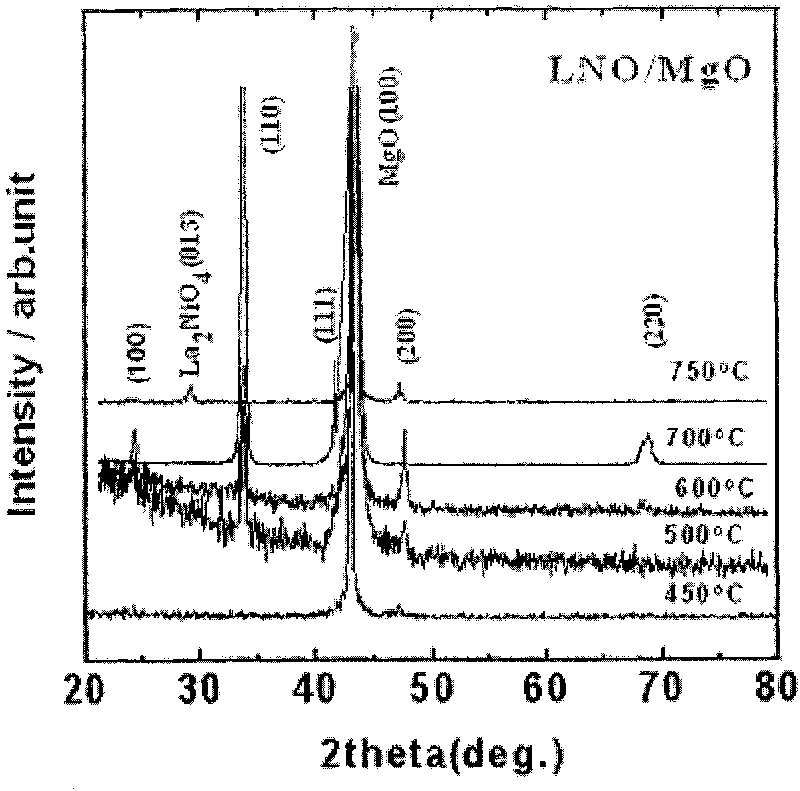

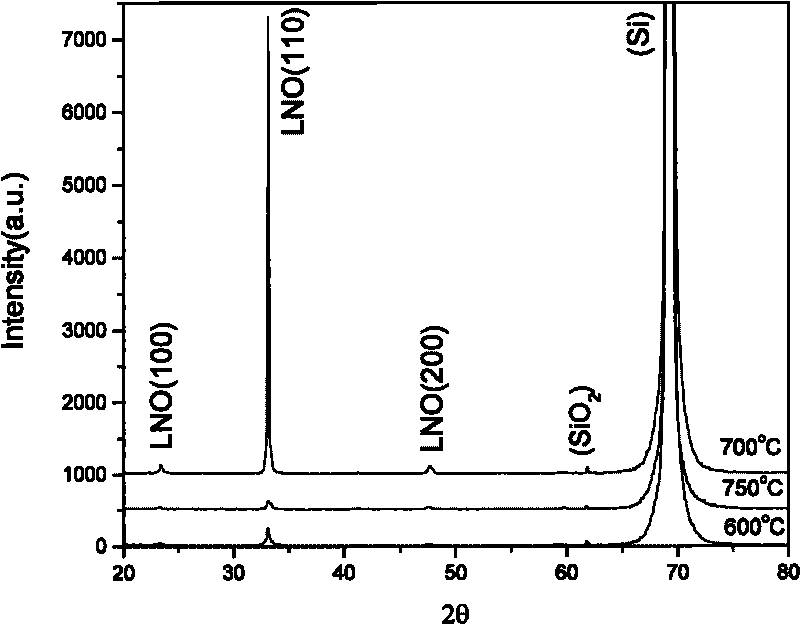

[0039]②. Carry out segmental roasting of the dry gel. The segmental roasting process is: room temperature → 200°C for 1.5 hours → 400°C for 3 hours → 750°C for 2 hours → naturally cool down to room temperature. Grinding to obtain black pure phase LNO powder;

[0040] ③, after the LNO powder is ground, add an appropriate amount of adhesive polyvinyl alcohol solution (PV...

Embodiment 2

[0044] The preparation method of the lanthanum nickelate ceramic target of the present invention comprises the following steps:

[0045] ①. Weigh an appropriate amount of lanthanum nitrate, nickel nitrate, and citric acid, so that the molar ratio is La 3+ : Ni 2+ :(C 6 h 8 o 7 ·H 2 (0)=1:1:5.5, miscible in 200ml deionized water, stirred with a magnetic stirrer and heated in a constant temperature water bath at 90°C for 3 hours to obtain a green transparent sol, then place the sol in a constant temperature drying oven at 140°C for 11 hour, light brown xerogel was obtained, which was ground into powder;

[0046] ②. Carry out segmental calcination of the xerogel. The process of segmental calcination is: room temperature → 210°C for 1.6 hours → 410°C for 3.2 hours → 760°C for 2.4 hours → naturally cool down to room temperature. Grinding to obtain black pure phase LNO powder;

[0047] ③, after the LNO powder is ground, add an appropriate amount of adhesive polyvinyl alcohol ...

Embodiment 3

[0051] The preparation method of the lanthanum nickelate ceramic target of the present invention comprises the following steps:

[0052] ①. Weigh an appropriate amount of lanthanum nitrate, nickel nitrate, and citric acid, so that the molar ratio is La 3+ : Ni 2+ :(C 6 h 8 o 7 ·H 2 (0)=1:1:5.5, miscible in 200ml deionized water, stirred with a magnetic stirrer and heated in a constant temperature water bath at 100°C for 4 hours to obtain a green transparent sol, then place the sol in a constant temperature drying oven at 150°C for 12 hour, light brown xerogel was obtained, which was ground into powder;

[0053] ②. Carry out segmental roasting of the xerogel. The segmental roasting process is: room temperature → 230°C for 1.7 hours → 430°C for 3.5 hours → 780°C for 3 hours → naturally cool down to room temperature. Grinding to obtain black pure phase LNO powder;

[0054] ③. After grinding the LNO powder, add an appropriate amount of binder polyvinyl alcohol solution (PVA...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com