Poly-arylene ether nitrile composite material, poly-arylene ether nitrile bar and preparation method thereof

A technology for poly(arylene ether nitrile) and composite materials is applied in the fields of poly(arylene ether nitrile) rods and their preparation, and poly(arylene ether nitrile) composite materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

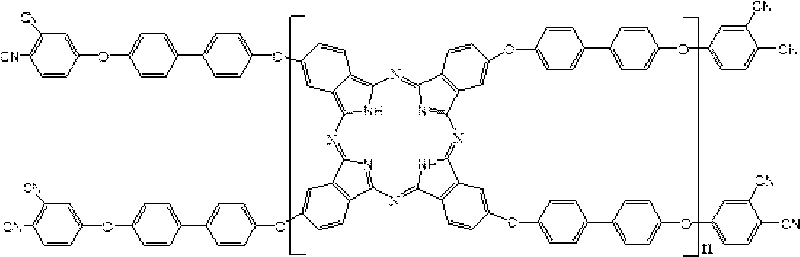

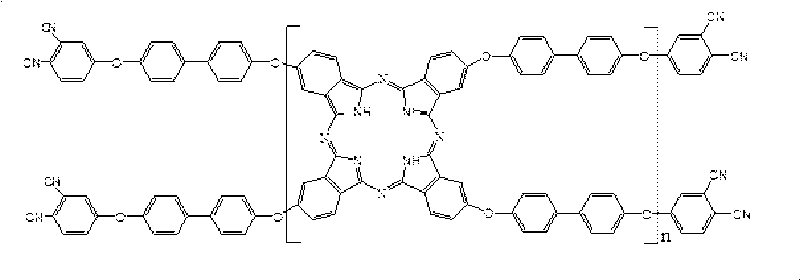

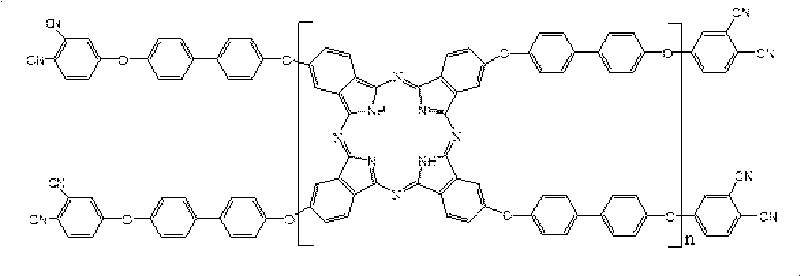

Image

Examples

Embodiment 1

[0043] Get 5640 grams of polyarylene ether nitrile, 180 grams of phthalonitrile prepolymers, 120 grams of graphite and 60 grams of silicon carbide whiskers and blend evenly and join in the single-screw extruder to control the extrusion of the single-screw extruder. The outlet temperature is 330-350°C, so that they are plasticized in the screw to obtain molten materials. Through the head of the extruder, the molten material is extruded into the mouth die through the filter plate, and then directly enters the cooling and calibrating sleeve. The length of the sizing sleeve is 120mm, and the diameter is D42mm. Under the joint action of the back pressure rod of the traction device and the extruder, the polyarylene ether nitrile melt moves forward at a constant speed, and is cooled and shaped by the sizing sleeve, so that the diameter is D41mm? mm polyarylether nitrile rods.

[0044] After the polyarylene ether nitrile rod is cut, it is placed in a box-type annealing furnace for a...

Embodiment 2

[0052] As in Example 1, only the formula is changed to 3780 grams of polyarylether nitrile, 300 grams of phthalonitrile prepolymer, 120 grams of graphite and 1800 grams of glass fiber are evenly blended and then added to the single-screw extruder, the same According to the method and process, polyarylether nitrile rods are obtained.

[0053] The roundness of the bar prepared in this embodiment is studied, and the diameter of the bar is measured at 5 different points on the prepared bar cross-section, and the results are as follows:

[0054] The polyarylene ether nitrile rod diameter data that table 3 embodiment 1 prepares

[0055]

[0056] The polyarylene ether nitrile bar performance data prepared by the embodiment 1 of table 4

[0057]

[0058]It can be seen from Tables 3 and 4 that the prepared polyarylene ether nitrile rods have a uniform cross-section and have high mechanical strength and heat resistance.

Embodiment 3

[0060] As in Example 1, just replace the formula with 4380 grams of polyarylether nitrile, 300 grams of phthalonitrile prepolymer, 120 grams of polytetrafluoroethylene and 1200 grams of carbon fiber and add them to the single-screw extruder after blending evenly , the same method and process to obtain polyarylether nitrile rods.

[0061] The roundness of the bar prepared in this embodiment is studied, and the diameter of the bar is measured at 5 different points on the prepared bar cross-section, and the results are as follows:

[0062] Table 5 polyarylene ether nitrile rod diameter data

[0063]

[0064] Table 6 polyarylether nitrile rod performance data

[0065]

[0066] It can be seen from Tables 5 and 6 that the prepared polyarylene ether nitrile rods have a uniform cross-section and have high mechanical strength and heat resistance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com