Silicon crystal growing device with two-way airflow

A growing device and silicon crystal technology, which is applied in the field of crystal growth into single crystal and silicon polycrystalline melting, can solve the problems of high production cost, abnormal growth, broken edges, etc., and achieve the effect of reducing corrosion, reducing contact area and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

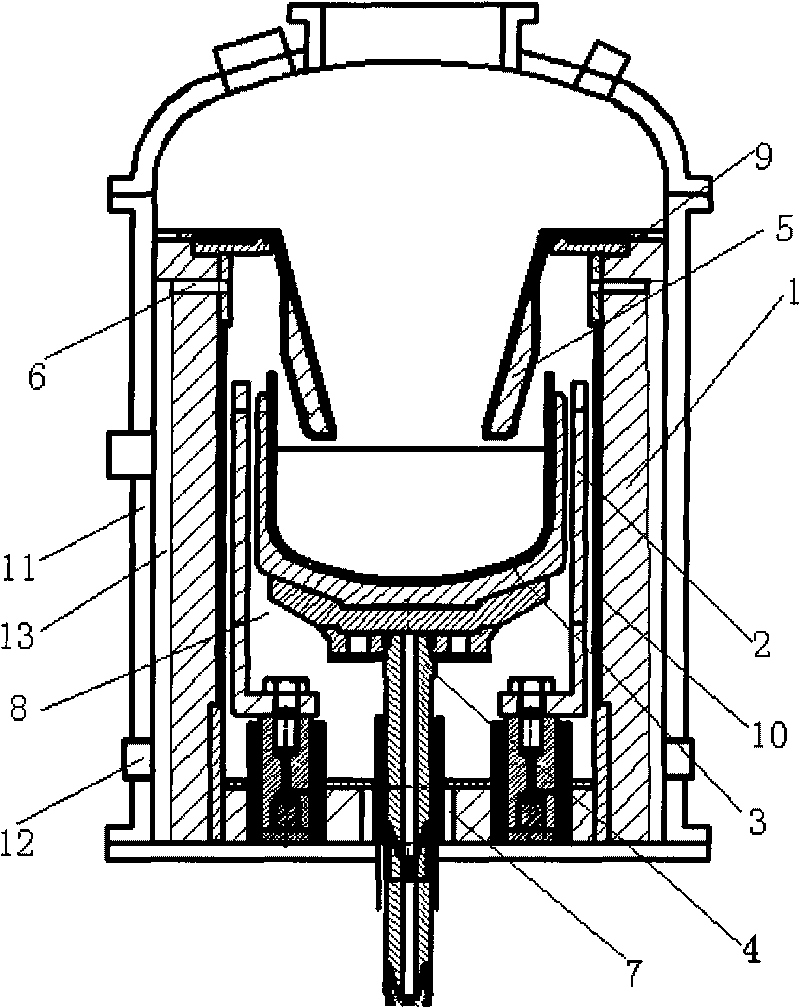

[0013] Referring to the accompanying drawings, the silicon crystal growth device with two-way air flow includes a furnace body 1, an upper insulation cylinder 9 is arranged on the inner wall of the furnace outside the guide cylinder 5, and a lower insulation cylinder 10 is arranged on the lower inner wall of the furnace body. A cylindrical heater 2 is placed in the inner cavity of the furnace body 1, and the two electrodes at the bottom of the heater 2 are respectively embedded in the bottom of the furnace body 1. A graphite crucible 3 is arranged in the inner cavity of the heater 2, and the graphite crucible 3 passes through the furnace The connecting rod 4 at the bottom of the body 1 is supported and fixed, and the upper opening of the body of furnace 1 is placed with a guide tube 5 that can extend into the inner cavity of the graphite crucible 3, and an exhaust port 6 is arranged on the side wall of the top of the body of furnace 1, and There is an argon gas inlet 7 at the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com