Cyanogens traniliprole suspending agent and preparation method thereof

A technology of cyantraniliprole and suspending agent, applied in the field of cyantraniliprole suspending agent and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

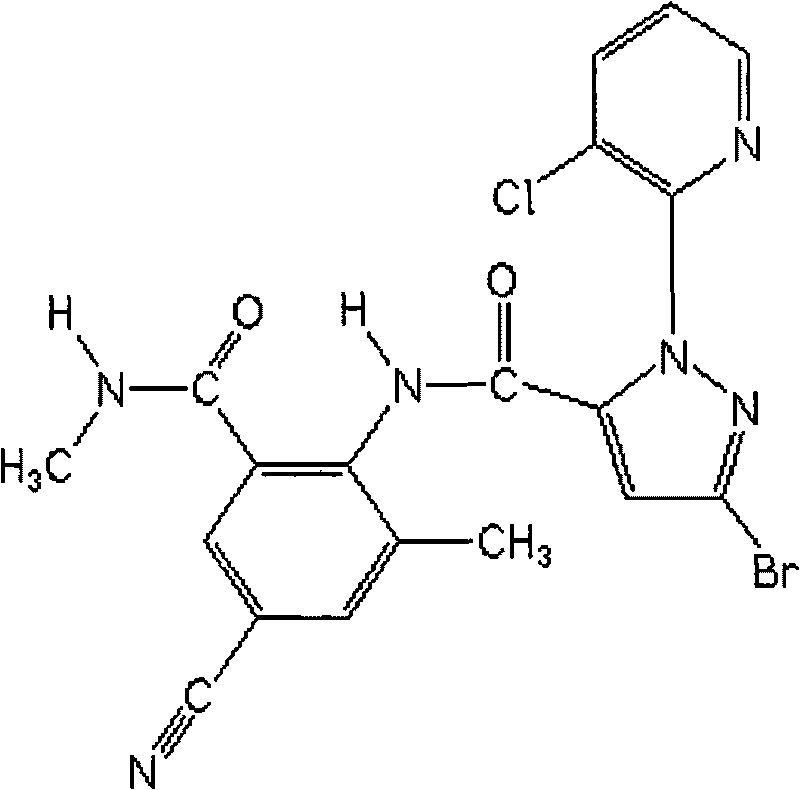

Image

Examples

Embodiment 1

[0024] Example 1: 5% Cytraniliprole SC

[0025] Add 3 grams of dispersant M-9 (lignosulfonate), 1.5 grams of nonylphenol polyoxyethylene ether (NP-10), 2 grams of JFC, 5 grams of propylene glycol, and 0.3 grams of silicone defoaming agent into a 150 mL beaker agent, 0.01 g sodium benzoate, 5 g bentonite, 0.4 g xanthan gum, 77.49 g water. Stir to completely dissolve the surfactant in the beaker in water, then add 5.3 grams of cyantraniliprole 95% industrial product, and then stir to make the material in the beaker finally form a slurry, which is poured into the laboratory with glass beads Use a 0.1L vertical small sand mill to grind continuously for 1.5 hours to obtain a suspension agent sample. The particle size of the sample was detected by a Malvern laser particle size distribution analyzer at room temperature, and the particle size was measured as D10=1.795 μm, D50=3.008 μm, and D90=4.368 μm. The suspension rate of the sample at room temperature was 96.3%. The sample was ...

Embodiment 2

[0026] Example 2: 10% Cytraniliprole SC

[0027] In a 150mL beaker, add 3 grams of EO / PO block copolymer phosphate, 1.5 grams of Nongru 602 * , 3 grams of penetrant TX, 5 grams of ethylene glycol, 0.3 grams of isooctyl alcohol, 0.01 grams of formaldehyde, 5 grams of bentonite, 0.4 grams of xanthan gum, 1 gram of triethanolamine, 70.19 grams of water. Stir to completely dissolve the surfactant in the beaker in the water, then add 10.6 grams of 95% cyantraniliprole industrial product. Stir again to make the material in the cup finally become a slurry. This slurry is poured into a laboratory 0.1L vertical small sand mill with glass beads, and sanded continuously for 1.5 hours to obtain a suspension agent sample. The particle size of the sample was detected by a Malvern laser particle size distribution analyzer at room temperature, and the particle size was measured as D10=1.9864 μm, D50=3.101 μm, and D90=4.892 μm. The suspension rate of the sample at room temperature is 96%. Th...

Embodiment 3

[0028] Example 3: 20% Cytraniliprole SC

[0029] Add 40 grams of dispersant sodium dibutylnaphthalene sulfonate formaldehyde condensate, 15 grams of nonylphenol polyoxyethylene ether (NP-15), 30 grams of JFC, 50 grams of ethylene glycol, and 3 grams of organic silicon into a 2000 mL beaker Antifoaming agent, 0.1 g sorbic acid, 20 g bentonite, 25 g xanthan gum, 198.1 g water. Stir to completely dissolve the surfactant in the beaker in water, then add 606.3 grams of 95% cyantraniliprole industrial product, and then stir to make the material in the cup finally become a slurry, which is continuously fed into a horizontal sand mill ( In the DYNO-mill laboratory sand mill), circulate the sand mill 3 times to obtain the suspension agent sample

[0030] The particle size of the sample was detected by a Malvern laser particle size distribution analyzer at room temperature, and the measured particle size was D10=1.864 μm, D50=3.015 μm, and D90=4.892 μm. The suspension rate of the samp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com