Method for composite treatment of dissimilar metal sheet by located irradiation and diffusion way

A dissimilar metal and composite treatment technology, which is applied in metal processing equipment, non-electric welding equipment, welding equipment, etc., can solve problems such as poor bonding in the detonator area, deformation of composite plates, and multi-layer bulging, etc., to achieve easy control, good operation, and combination good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

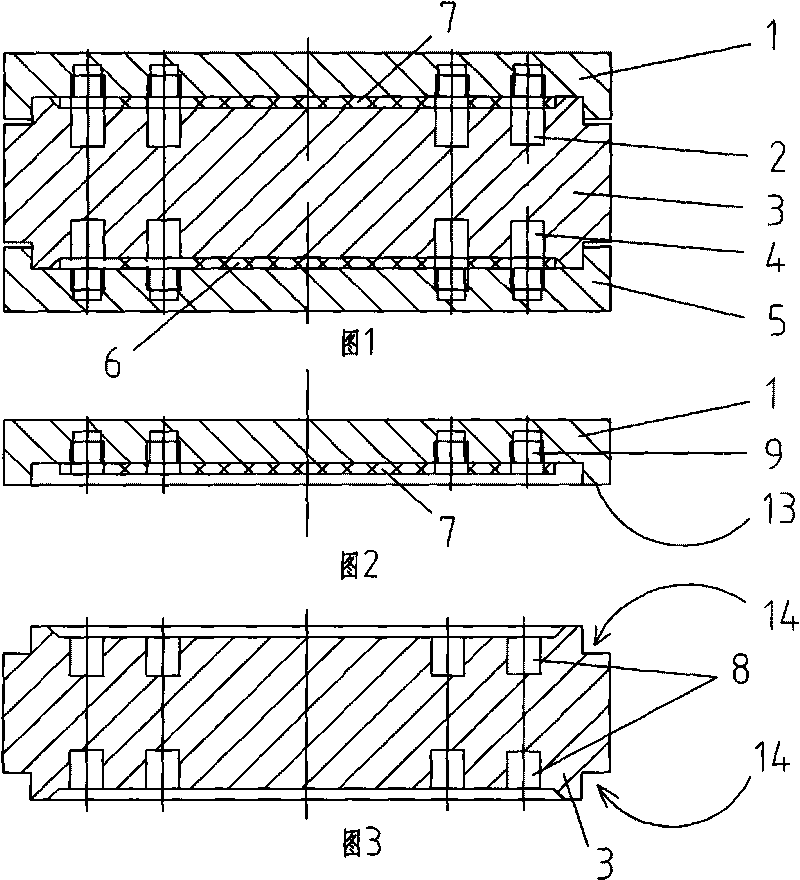

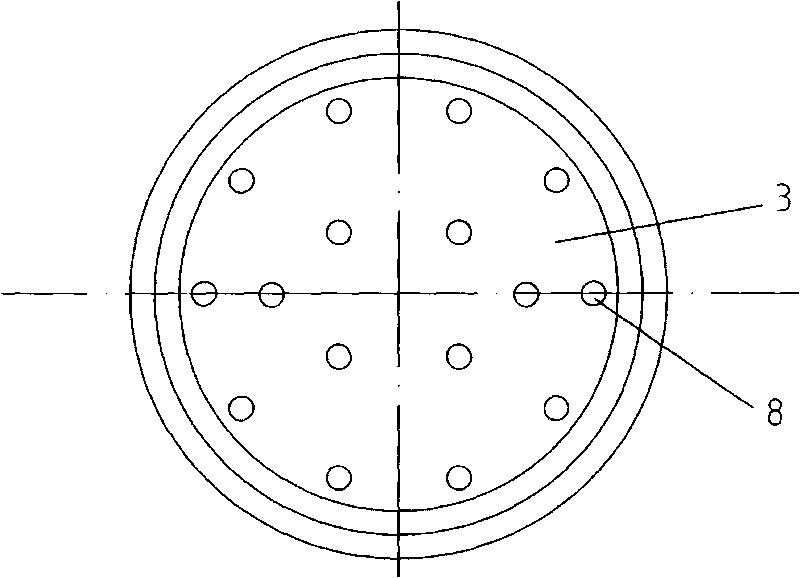

[0033] Embodiment 1: as figure 1 , 2 , 3, 4, and 5 show:

[0034] a. Set up a radiation diffusion connection layer between the base layer 3 (selecting carbon steel) made of dissimilar metals, the upper cladding layer 1 (selecting pure titanium material) and the lower cladding layer 5 (selecting pure titanium material) and perform mutual positioning treatment, specifically The method is to place an upper lining layer 7 between the base layer 3 and the upper cladding layer 1, and place a lower lining layer 6 between the base layer 3 and the lower cladding layer 5. The upper lining layer 7 and the lower lining layer 6 are made of thin copper plate materials. Diffusion connection layer. On the upper cladding 1, the upper cladding screw holes 9 are processed, on the lower cladding 5, the lower cladding screw holes 10, 2 are upper positioning nails of copper material, and the positioning holes 8 are processed on the base layer 3. One end of the upper positioning nail 2 has thread...

Embodiment 2

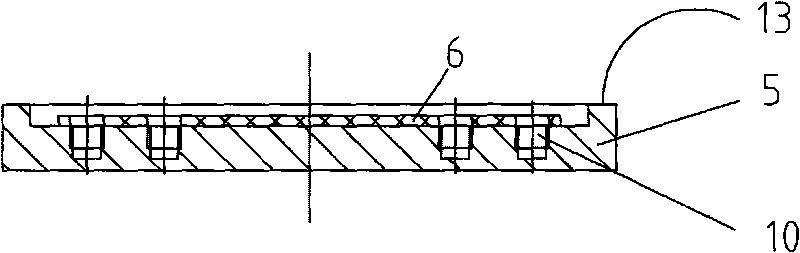

[0042] Embodiment 2: as Image 6 , 7, 8, and 9: the difference from embodiment 1 is that the radiation diffusion connection layer is a cross surfacing layer welded in the middle groove 11 on the base layer 3 and surfacing on the base layer 3, and is in contact with the surfacing layer The welding surfacing layer on the upper cladding layer 1 is in contact with, wherein the material of the surfacing layer is copper. The positioning process is to process a convex edge 13 on the periphery of the upper layer 1, and process a concave edge 14 matching the convex edge 13 on the periphery of the base layer 3. The convex edge 13 and the concave edge 14 can cooperate with each other for mutual positioning. prevent mutual misalignment. Others are the same as in Example 1.

Embodiment 3

[0043] Embodiment 3: as Figure 10 , 11 , shown in 12 and 13: the difference shown in embodiment 2 is that a transparent middle through hole 17 and a cross-through groove 16 communicated with the hole are processed on the upper cladding layer 1, and on the periphery of the upper cladding layer 1 The surfacing welding has a surfacing welding edge 15, and the surfacing welding edge 15 coincides with the concave edge around the base layer 3. The radiation diffusion connection layer is formed by pressing the surfacing solder and the surfacing edge 15 welded in the middle through hole 17 and the cross-through groove 16, and the others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com