Technology of preparing aluminium oxide based continuous fibers by sol-gel process

A sol-gel method and continuous fiber technology, which is applied in the field of continuous alumina-based fiber preparation technology, can solve the problems of high sintering temperature, and achieve the effects of low preparation cost, stable physical and chemical properties, and good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with specific examples.

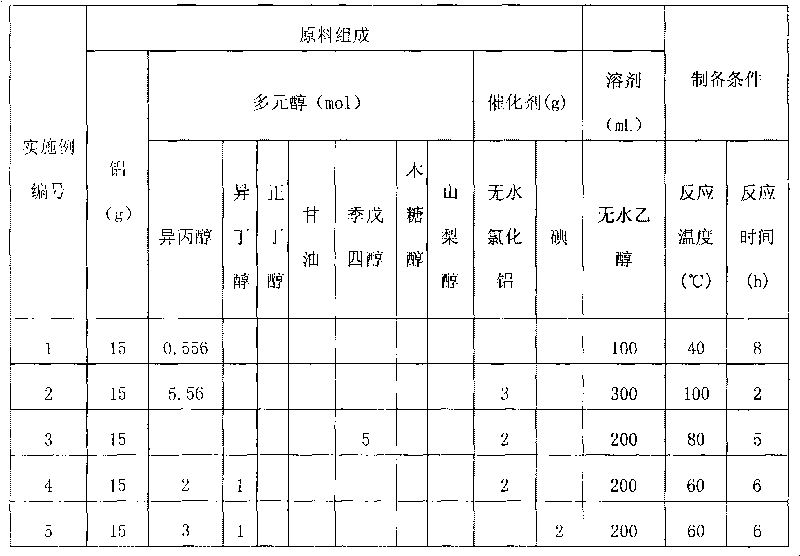

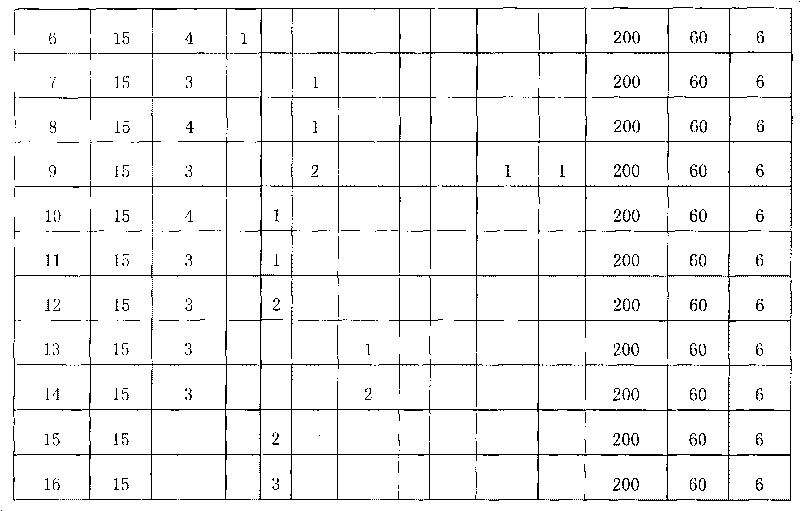

[0020] Table 1 has listed numbering as 16 embodiment first step processes of 1-16: determine the kind and the addition of aluminum powder, dehydrated alcohol, polyhydric alcohol and catalyst according to the different embodiments of table 1, and determine the amount of aluminum alkoxide Preparation conditions, prepare aluminum alkoxide.

[0021] Table 1. Preparation of aluminum alkoxide solutions

[0022]

[0023]

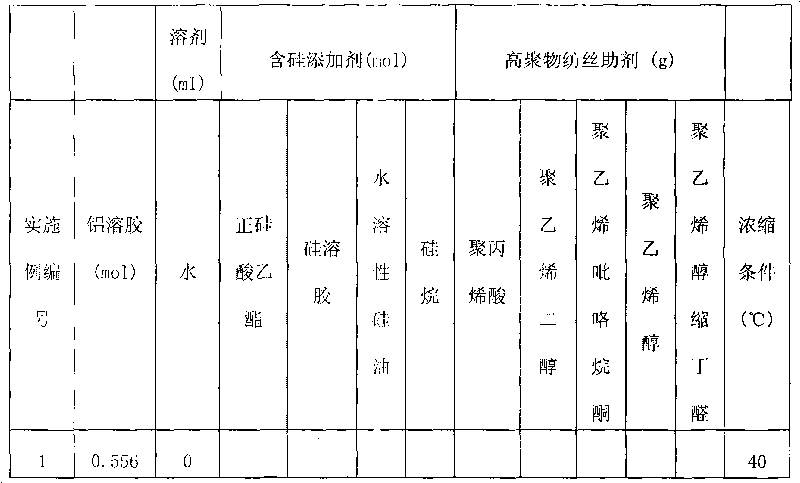

[0024] Table 2 has listed the second and third step process conditions of the embodiment of table 1: add water (can not add, as embodiment 1), silicon-containing additive, spinning aid in the aluminum alkoxide solution according to the different embodiments of table 2 , according to the concentration conditions in the table to prepare the alumina-based fiber precursor sol.

[0025] Table 2. Preparation of alumina-based fiber precursor sol

[0026...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com