Technological method and equipment for preparing biodiesel by using palm oil

A technology of biodiesel and process method, which is applied in the fields of chemistry, energy, and chemical industry, and can solve problems such as inconvenient operation, uncontrollable reactant composition, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

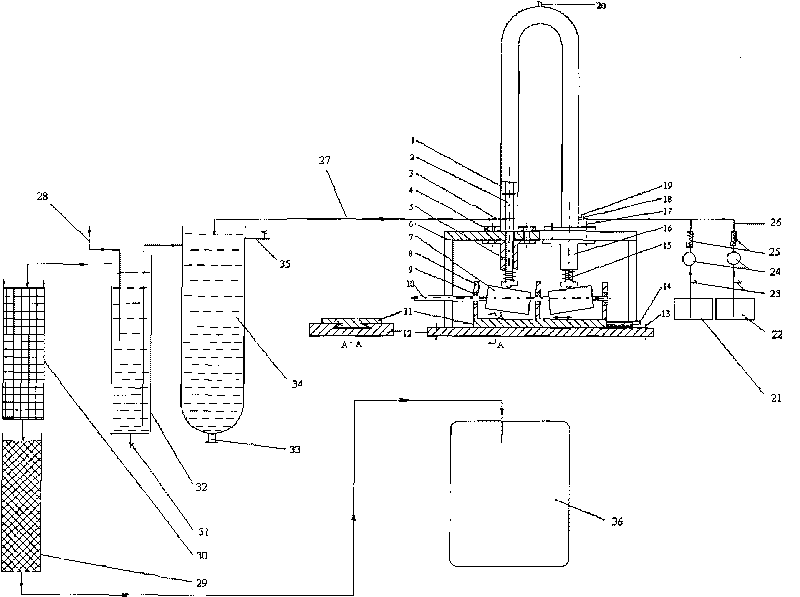

[0040] Embodiment 1, refer to figure 1 . This example takes the inverted U-shaped tube reactor 1 as an example, prepare a mixture of methanol and catalyst at a ratio of dissolving 20 grams of sodium methoxide per liter of methanol, close the valve 23, store the mixture in a vessel 21, and mix it at a temperature of 40 ° C. 1 hour. Adjust the frequency to 4Hz, adjust the amplitude to 3mm, turn on the oscillation device, and adjust the metering pump 24: make CH 3 The flow rate of OH+NaOMe mixture is 0.509l / h, the flow rate of palm oil is 2.591l / h, the reactants (catalyst-containing methanol and palm oil) are extracted from the respective vessels, and heated to 60°C and input into reactor 1 . After the reaction is completed under the above parameters, the product (crude biodiesel+glycerin) first enters the separator 34 for separation, and the separated methanol-containing crude biodiesel enters the water washer 32 to wash away the methanol. The washed biodiesel first passes ...

Embodiment 2

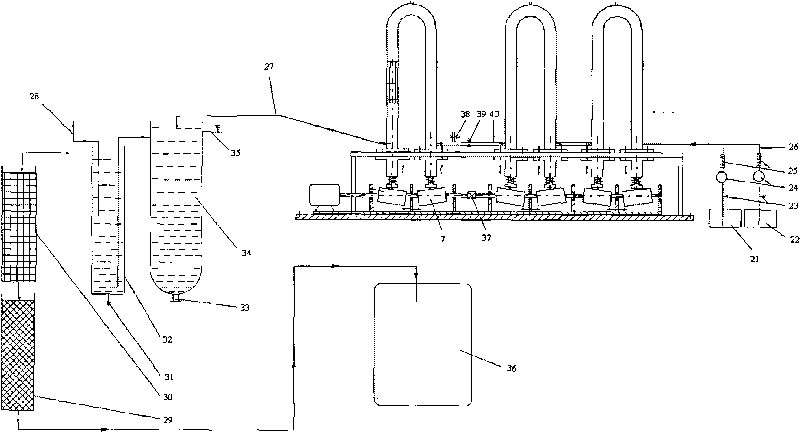

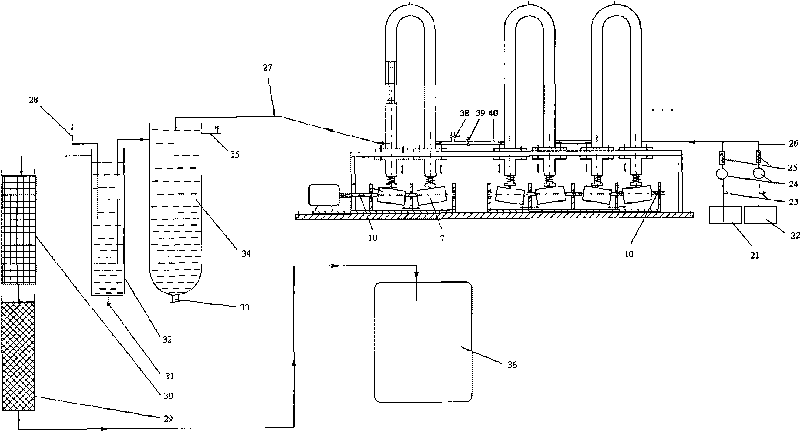

[0042] Embodiment 2, when a large production volume requires multi-level strengthening, it can be used figure 2 or 3 options. All the other are with embodiment 1.

Embodiment 3

[0043] Embodiment 3, the embodiment of the reactor of other forms is as Figure 7-13 , 20-28. All the other are with embodiment 1. When the diameter of reactor 1 is bigger, can adopt hollow piston 5, refer to Figure 7 , 8 , 26-28.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com