Anode composite material of lithium sulfur battery and preparation method thereof

A composite material, lithium-sulfur battery technology, applied in battery electrodes, circuits, electrical components and other directions, can solve the problems of general working voltage stability, poor conductivity of positive electrode materials, low battery cycle stability, etc., and achieves a simple and feasible preparation method. Excellent electrical conductivity and improved electrochemical reversibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Weigh elemental sulfur (100 mesh, Aldrich) and unsubstituted polythiophene (PTh) with a mass ratio of 25:75, put PTh in a vacuum ball mill tank, remove the air in the tank and inject N 2 As an inert gas shielding gas for 10 to 30 minutes. Ball mill at room temperature for 3 to 12 hours, add the weighed elemental sulfur after the tank body is cooled, then remove the air in the tank body, pass in protective gas Ar for about 10 to 30 minutes, and put the tank at 80 to 120°C The temperature is kept constant for 3-6 hours to obtain a sulfur content of 25% in the composite material.

[0027] The battery was discharged at a constant current with a current density of 50mA / g, and the charging lower limit voltage was 1V, and then charged with a constant current at a current density of 50mA / g, and the charging upper limit voltage was 3.0V, and the charging and discharging cycle was 50 times. The first discharge specific capacity of the sulfur electrode is 851.4mAh / g, and two obvi...

Embodiment 2

[0029] Weigh elemental sulfur and unsubstituted polythiophene (PTh) with a mass ratio of 30:70, put PTh in a vacuum ball mill tank, remove the air in the tank and inject N 2 As an inert gas shielding gas for 10 to 30 minutes. Ball mill at room temperature for 3 to 12 hours, add the weighed elemental sulfur after the tank body is cooled, then remove the air in the tank body, pass in protective gas Ar for about 10 to 30 minutes, and put the tank at 80 to 120°C The temperature is kept constant for 3-6 hours to obtain a sulfur content of 30% in the composite material.

[0030] The battery was discharged at a constant current with a current density of 50mA / g, and the charging lower limit voltage was 1V, and then charged with a constant current at a current density of 50mA / g, and the charging upper limit voltage was 3.0V, and the charging and discharging cycle was 50 times. The first discharge specific capacity of the sulfur electrode is 1000.4mAh / g, and there are 2.3V and 2.1V dis...

Embodiment 3

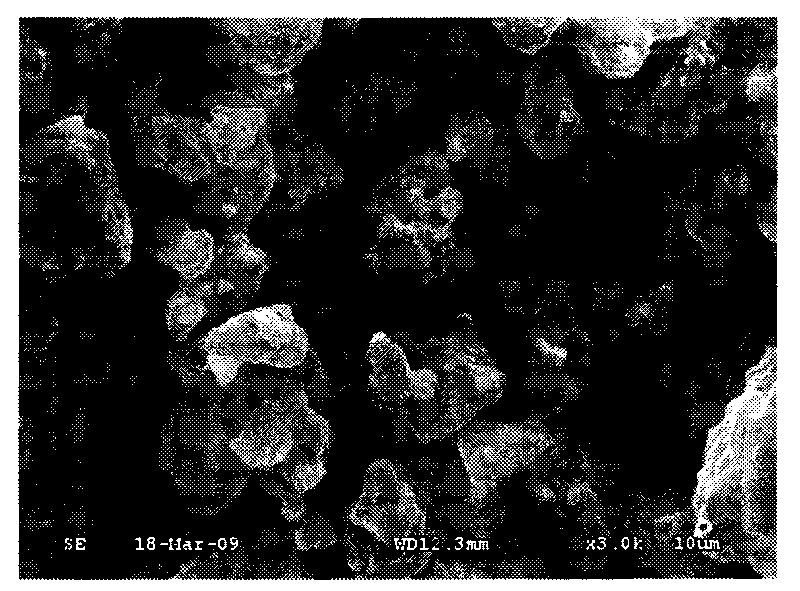

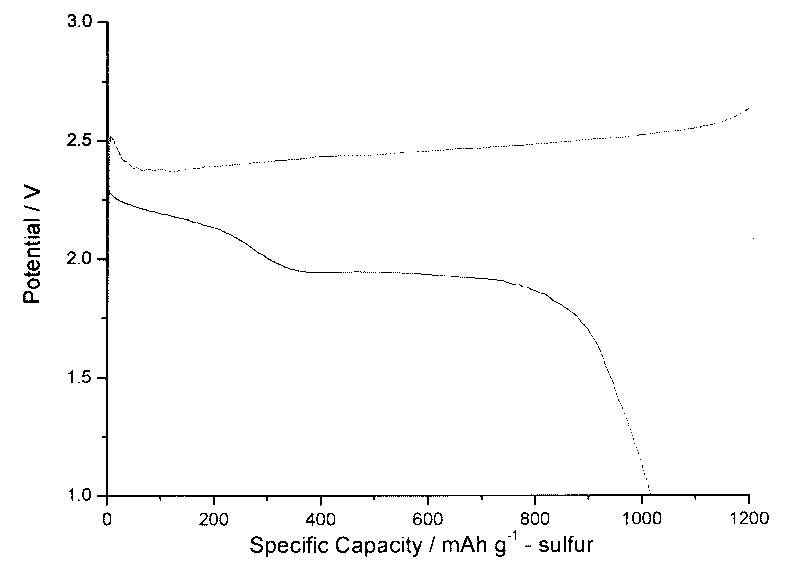

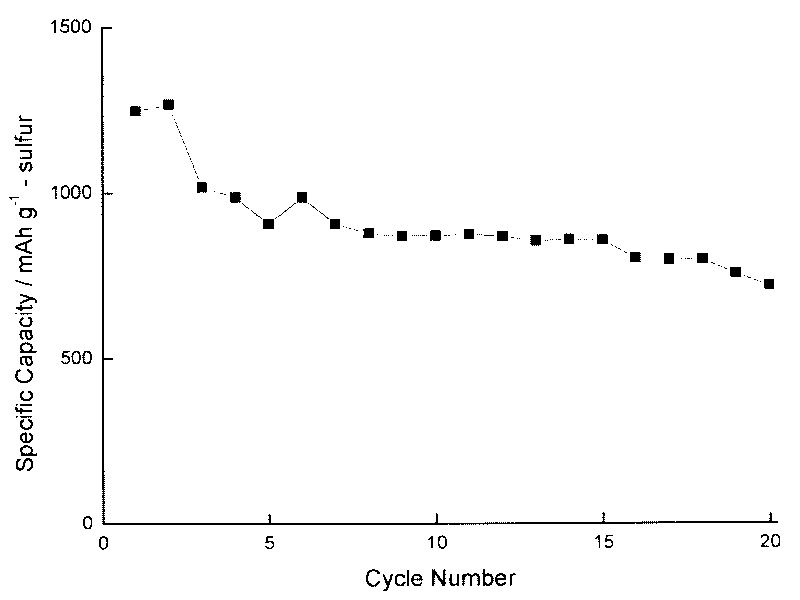

[0032] Weigh sublimed sulfur and unsubstituted polythiophene (PTh) with a mass ratio of 40:60, place PTh in a vacuum ball mill tank, remove the air in the tank and inject N 2 As an inert gas shielding gas for 10 to 30 minutes. Ball mill at room temperature for 3 to 12 hours, add the weighed elemental sulfur after the tank body is cooled, then remove the air in the tank body, pass in protective gas Ar for about 10 to 30 minutes, and put the tank at 80 to 120°C The temperature is kept constant for 3-6 hours to obtain a sulfur content of 40% in the composite material.

[0033] The battery is charged and discharged 50 times at 100mA / g, and the range is 1-3V. The initial discharge specific capacity of the sulfur electrode was 1003.2mAh / g, and the discharge specific capacity remained at 808.2mAh / g after 20 cycles, showing good cycle stability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com