Method for strengthening joint stability by using rhBMP-2 release coating on surface of artificial joint

An artificial joint, rhbmp-2 technology, applied in coatings, medical science, prosthesis, etc., can solve the problems of uncontrollable action time of sustained release, difficulty in inducing osteogenesis of BMP-2, etc., and achieve good sustained release effect , Good drug compatibility, uniform combination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

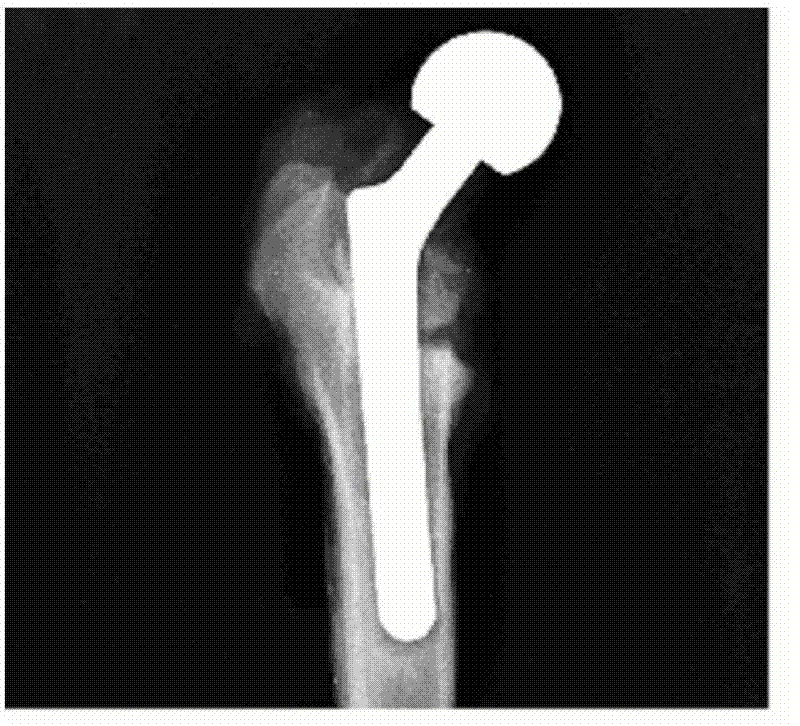

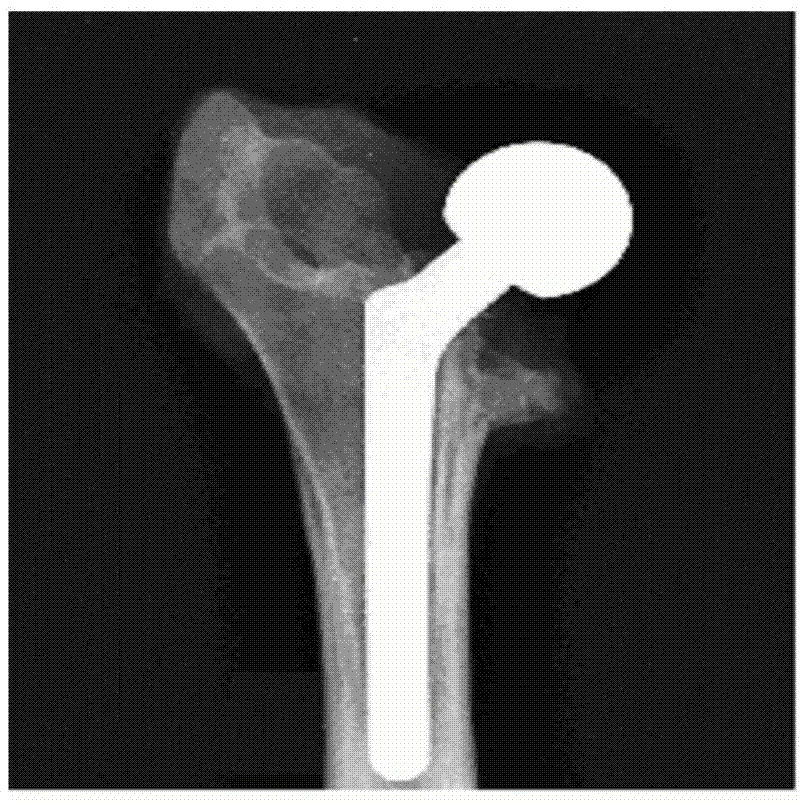

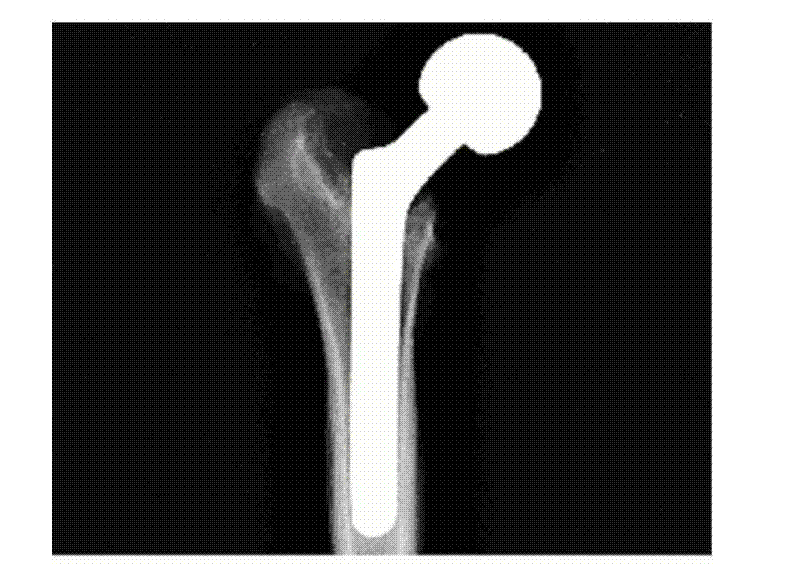

Image

Examples

specific Embodiment approach 1

[0009] Specific embodiment 1: The method for enhancing joint stability by the rhBMP-2 slow-release coating on the surface of the artificial joint in this embodiment is realized according to the following steps: 1. Mix 35-60 mg of ethyl cellulose (EC) and 8-12 mg of polyethylene glycol Diol (PEG) 4000 was added to 1.5-3ml of chloroform, then ultrasonically dissolved at 25°C, then 1 mg of BMP-2 was added, and BMP-2 mixture was obtained after ultrasonic dispersion; 2. Spray the BMP-2 mixture Put it on the artificial femoral stem, then place it in the ultra-clean workbench to dry, pack it in a sealed bag, and sterilize it at low temperature, and it is completed; the thickness of the BMP-2 mixed liquid spraying in step 2 is 30±10 μm.

[0010] In this embodiment, the artificial femoral stem will be scrubbed and disinfected with 70% ethanol with a mass concentration.

[0011] In this embodiment, the artificial femoral stem is an existing artificial femoral stem made of various materi...

specific Embodiment approach 2

[0012] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in step 1, 35 mg of ethyl cellulose (EC) and 8 mg of polyethylene glycol (PEG) 4000 are added to 1.5 ml of chloroform. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0013] Embodiment 3: The difference between this embodiment and Embodiment 1 is that in step 1, 60 mg of ethyl cellulose (EC) and 12 mg of polyethylene glycol (PEG) 4000 are added to 3 ml of chloroform. Other steps and parameters are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com