Method for separating vitamin E polyethylene glycol succinate monoester from vitamin E polyethylene glycol succinate diester

A technology of polyethylene glycol succinate and polyethylene glycol succinic acid, which is applied in the field of separation of vitamin E polyethylene glycol succinic acid mono- and di-esters, can solve unseen and complicated problems, and achieve low consumption , high degree of automation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

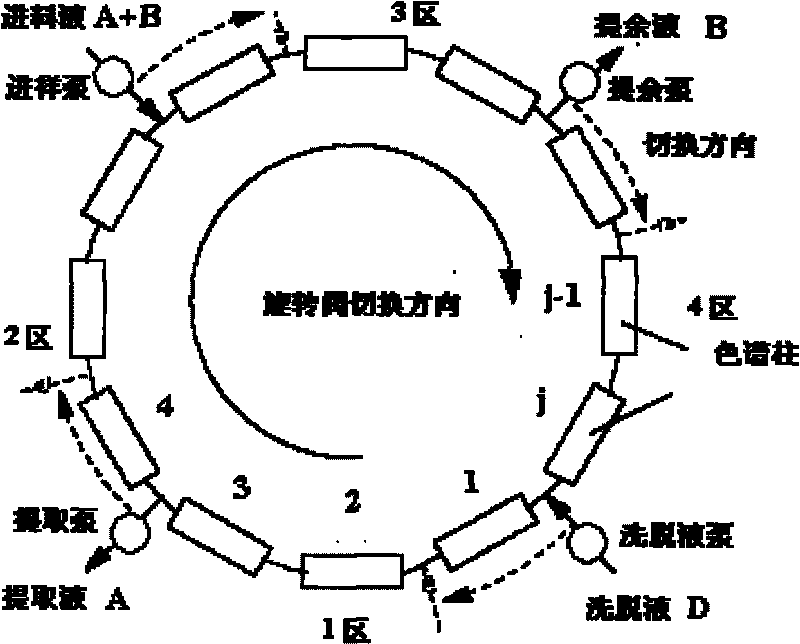

Method used

Image

Examples

Embodiment 1

[0026] Simulated Moving Bed Chromatography System C9812 (Norr, Germany), equipped with 8 chromatographic columns (ID 1×15cm), 2 in each zone, the stationary phase filled in the chromatographic column is octadecylsilane bonded silica gel, particle size 50 μm. The mobile phase was acetonitrile / isopropanol solution (50 / 50, v / v), and the temperature was 35°C. The sample used for feeding is TPGS 1000 mixed solution, concentration: 200mg / ml, wherein the monoester content is 68.3%, and the diester content is 31.4%.

[0027] A. Operating conditions:

[0028] Injection liquid flow rate: UF=1ml / min

[0029] Eluent flow rate: UD=5.7ml / min

[0030] Raffinate flow rate: U R =3.0ml / min

[0031] Extraction flow rate: U E =3.7ml / min

[0032] Switching time: t s =144s

[0033] B. Finished product analysis:

[0034] The raffinate and extract composition were analyzed by HPLC. The purity of TPGS monoester in the raffinate is 98.2%, and the yield is 99.2%; the purity of TPGS diester i...

Embodiment 2

[0036] Simulated Moving Bed Chromatography System C9812 (Norr, Germany), equipped with 24 chromatographic columns (ID 1×15cm), 6 in each zone, the stationary phase packed in the chromatographic column is octadecylsilane bonded silica gel, particle size 5 μm. The mobile phase was acetonitrile / isopropanol solution (70 / 30, v / v), and the temperature was 0°C. The sample used for feeding is TPGS 400 mixed solution, concentration: 20mg / ml, wherein the monoester content is 20.1%, and the diester content is 79.8%.

[0037] A. Operating conditions:

[0038] Injection liquid flow rate: U F =1ml / min

[0039] Eluent flow rate: U D =8.18ml / min

[0040] Raffinate flow rate: U R =3.2ml / min

[0041] Extraction flow rate: U E =5.9ml / min

[0042] Switching time: t s =180s

[0043] B. Finished product analysis:

[0044] The raffinate and extract composition were analyzed by HPLC. The purity of TPGS monoester in the raffinate is 99.9%, and the yield is 99.9%; the purity of TPGS diester...

Embodiment 3

[0046] Simulated Moving Bed Chromatography System C9812 (Norr, Germany), equipped with 32 chromatographic columns (ID 1×15cm), 8 in each zone, the stationary phase packed in the chromatographic column is octadecylsilane bonded silica gel, particle size 20 μm. The mobile phase was acetonitrile / isopropanol solution (50 / 50, v / v) at a temperature of 50°C. The sample used for feeding is TPGS 400 mixed solution, concentration: 300 mg / ml, wherein the monoester content is 55.1%, and the diester content is 44.6%.

[0047] A. Operating conditions:

[0048] Injection liquid flow rate: U F =2ml / min

[0049] Eluent flow rate: U D =21.2ml / min

[0050] Raffinate flow rate: U R =9.19ml / min

[0051] Extraction flow rate: U E =14.0ml / min

[0052] Switching time: t s =60s

[0053] B. Finished product analysis:

[0054] The raffinate and extract composition were analyzed by HPLC. The purity of TPGS monoester in the raffinate is 98.9%, and the yield is 99.9%; the purity of TPGS diest...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com