Method for preparing modification functional groups on external surfaces of pores of mesoporous silica material

A technology of functional groups and outer surfaces, which is applied in the field of mesoporous silica materials, can solve the problems of affecting selective adsorption capacity and adsorption capacity, affecting material screening capacity, and hindering adsorption, so as to improve screening capacity and adsorption Improvement of action and reduction of clogging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) Preparation of mesoporous silica powder containing pore-forming agent:

[0026] After mixing the above raw materials with cetyltrimethylammonium bromide, tetraethoxysilane, ammonia water, sodium hydroxide and water in a molar ratio of 0.1:1.0:3.2:0.3:80, stir at room temperature for 3 hours Finally, the mixture was transferred to a polytetrafluoro reactor for crystallization at 100° C. for 120 hours, then filtered, washed, and dried. (Chu, C.T-W., ect, J. Am. Chem. Soc., 114(1992) 10834.)

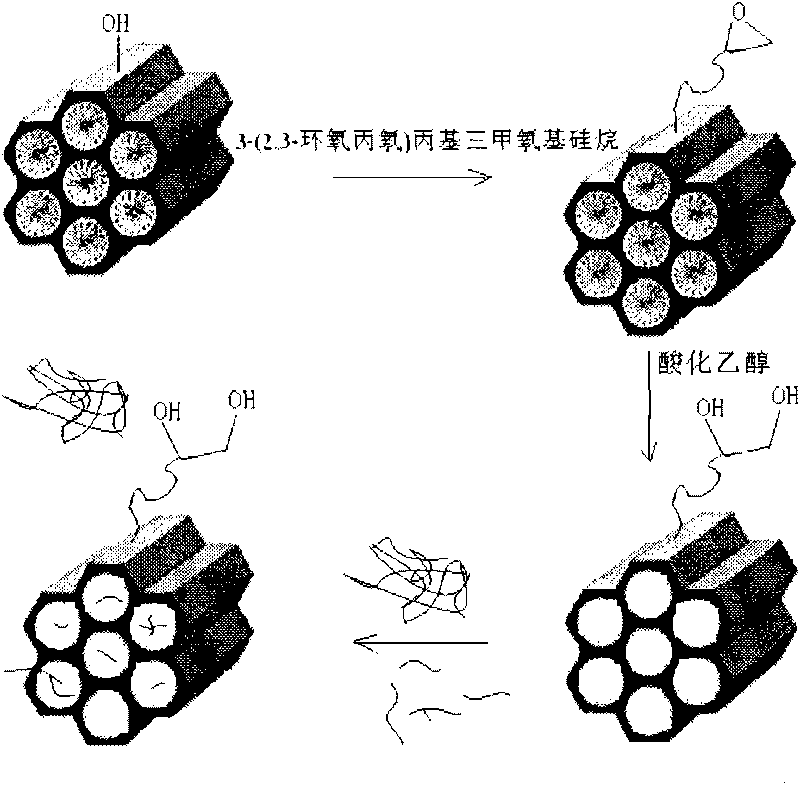

[0027] 2) The step of modifying the material includes: drying 1.0 g of mesoporous MCM-41 silica powder containing cetyltrimethylammonium bromide in vacuum at 100° C. for 10 hours. Add the dried material containing the pore-forming agent into a round-bottomed flask, and add 50mL of dry toluene to the flask under nitrogen protection. After the material is completely dispersed in toluene, add 3mL of 3-(2,3-epoxypropylene Oxy)propyltrimethoxysilane, under the protection of nitrogen,...

Embodiment 2

[0031] 1) Preparation of mesoporous silica powder containing pore-forming agent:

[0032] After mixing the above raw materials with cetyltrimethylammonium bromide, tetraethoxysilane, ammonia water, sodium hydroxide and water in a molar ratio of 0.1:1.0:3.2:0.3:80, stir at room temperature for 3 hours Finally, the mixture was transferred to a polytetrafluoro reactor for crystallization at 100° C. for 120 hours, then filtered, washed, and dried. (Chu, C.T-W., ect, J. Am. Chem. Soc., 114(1992) 10834.)

[0033] 2) The step of modifying the material includes: drying 2.0 g of mesoporous MCM-41 silica powder containing cetyltrimethylammonium bromide in vacuum at 80° C. for 16 hours. Add the dried material containing the pore-forming agent into a round-bottomed flask, and add 100 mL of dry n-hexane into the flask under nitrogen protection. After the material is completely dispersed in n-hexane, add 6 mL of 3-(2,3-cyclo Oxypropoxy)propyltrimethoxysilane was refluxed at 60° C. for 24 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com