Method for casting cylinder cover of low-speed diesel for large-bore vessel

A cylinder head and diesel engine technology, applied in the direction of casting molding equipment, casting molds, casting mold components, etc., can solve the problems of uneven product materials, large product processing allowances, local stress concentration, etc., to shorten the production cycle and reduce production costs The effect of reducing and reducing the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

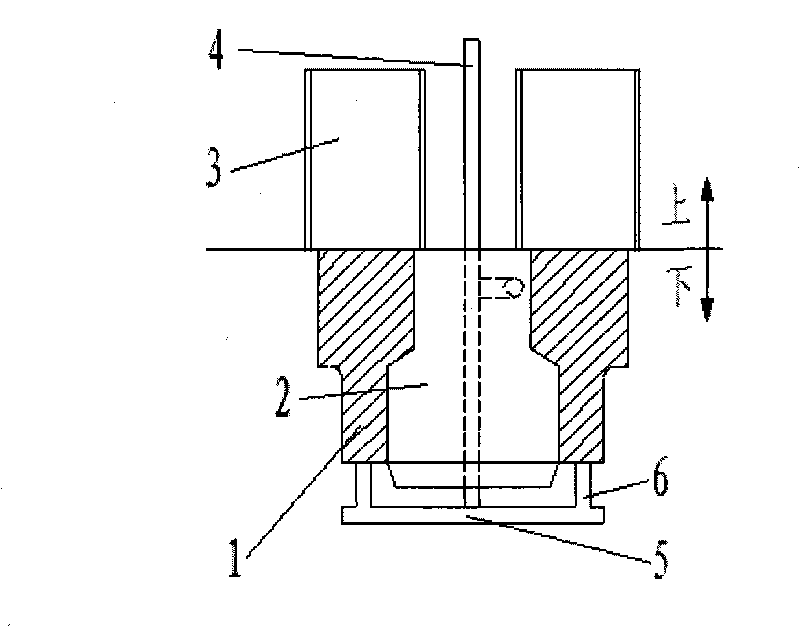

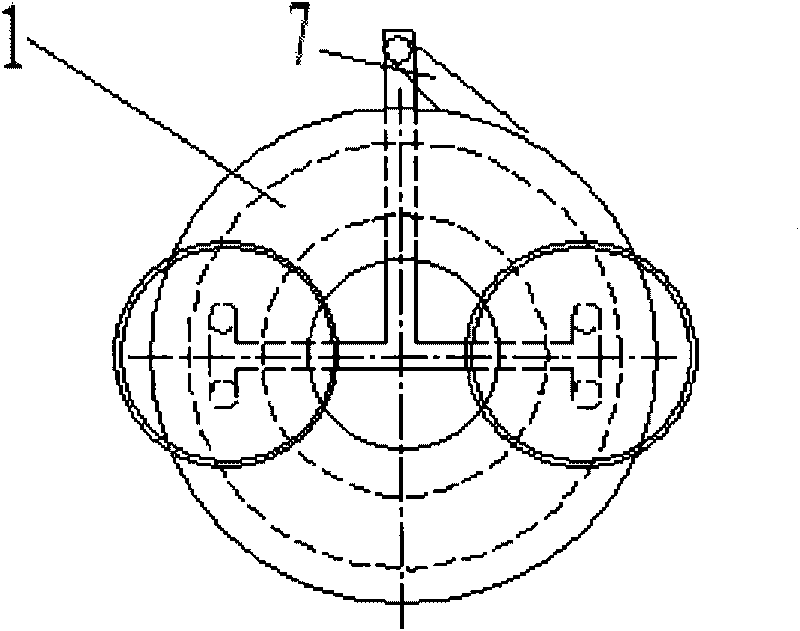

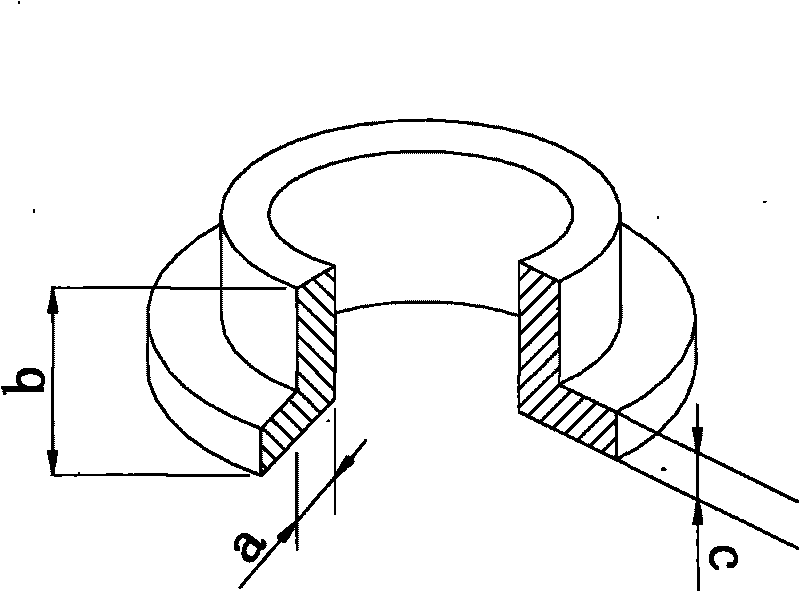

[0026] In order to illustrate the casting method of the cylinder head of the marine low-speed large-bore diesel engine of the present invention, the practical application of the method of the present invention is described in detail by taking the casting process of the cylinder head of the S70MC marine low-speed large-bore diesel engine as an example.

[0027] The parameters of S70MC marine low-speed large-bore diesel engine cylinder head castings are as follows:

[0028] Dimensions of casting: Φ1322mm×650mm;

[0029] Maximum wall thickness of the casting (at the exhaust valve): 467mm

[0030] Minimum casting wall thickness: 177mm

[0031] Casting blank weight: ~4700kg

[0032] The volume of the whole casting: 568145941mm 3

[0033] The entire casting surface area: 5770550mm 2

[0034] Casting cross-sectional area: 210961mm 2

[0035] Circumference of casting cross section: 2131mm

[0036] According to the casting method of the present invention, the casting of the cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com