System for recycling and treating coking wastewater

A treatment system and technology for coking wastewater, applied in water/sewage treatment, multi-stage water/sewage treatment, flotation water/sewage treatment, etc., can solve problems that have not been practically applied, achieve stable treatment effect, and easy operation , The effect of low production and operation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

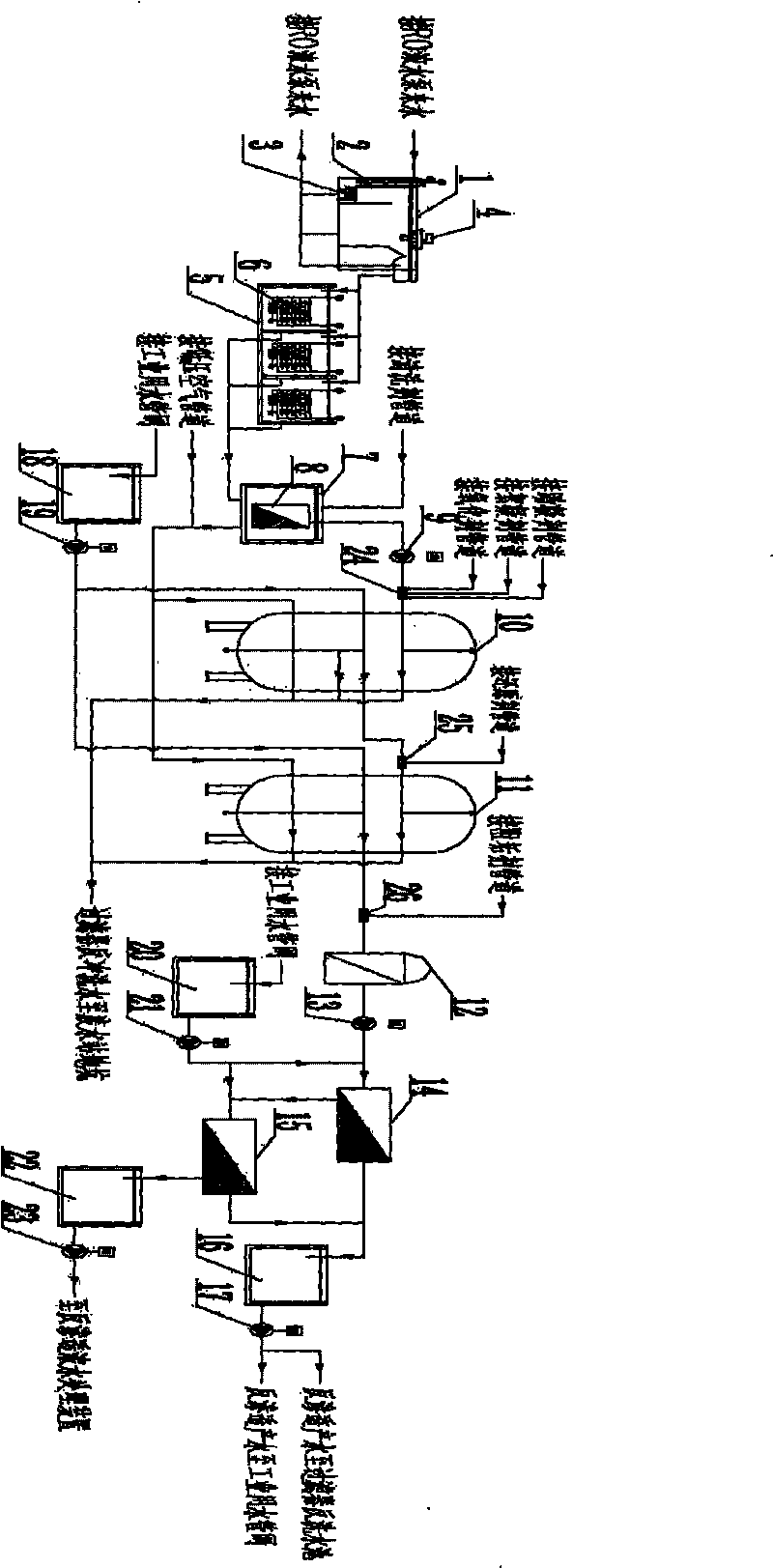

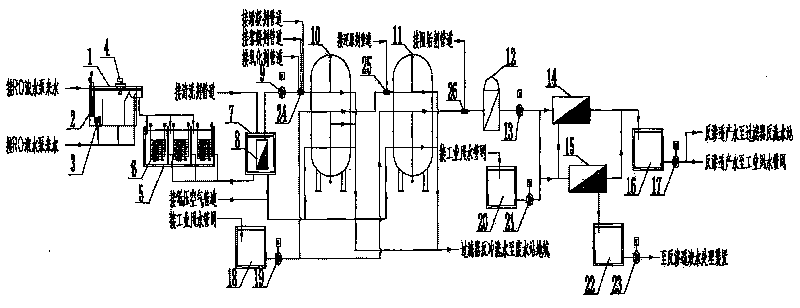

[0031] Referring to the accompanying drawings, the present invention is a coking wastewater reuse treatment system, which includes an electrocoagulation air flotation tank 1, an electrocoagulation electrode 2, an electric flotation electrode 3, an electrocoagulation air flotation slag scraper 4, an electrocatalytic oxidation cell 5, an electric Catalytic oxidation electrode 6, membrane bioreaction tank 7, membrane bioreactor 8, membrane bioreactor outlet pump 9, multimedia filter 10, activated carbon filter 11, security filter 12, reverse osmosis high pressure pump 13, the first section Reverse osmosis device 14, second-stage reverse osmosis device 15, reverse osmosis production tank 16, reverse osmosis production water delivery pump 17, filter backwashing tank 18, filter backwashing pump 19, reverse osmosis cleaning tank 20, reverse osmosis cleaning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com