Environment-friendly aqueous road paint and manufacturing method thereof

A manufacturing method, environmentally friendly technology, applied in the direction of coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] According to the percentage by weight, the environment-friendly water-based road paint mainly includes the following components: deionized water: 1.6%; hydroxyethyl cellulose: 0.1%; ammonia water: 0.2%; photocatalyst slurry: 10%; dispersant: 0.5% ; Acrylic emulsion: 33%; Wetting agent: 0.2%; Ground calcium carbonate: 38.5%; Rutile titanium dioxide: 9%; Defoamer: 0.4%; %. The defoamer in the above composition is SN-328 defoamer, and the film-forming aid is TEXANOL solvent.

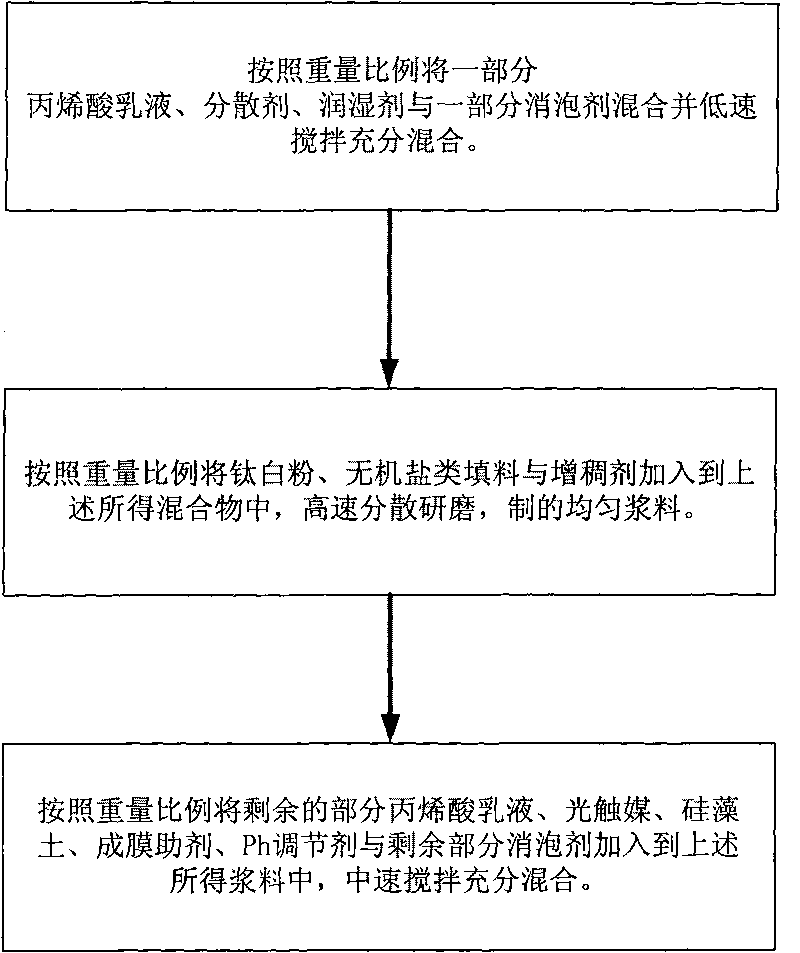

[0040] The above composition according to figure 1 The technological process shown is prepared, and it mainly comprises the following steps:

[0041] Step a: Weigh the raw materials according to the weight ratio of the above composition, add 10% acrylic emulsion, 0.5% dispersant, 0.2% wetting agent and 0.3% defoamer in sequence, stir at low speed for 5-10 minutes and mix thoroughly:

[0042] Step b: Add 9% of rutile titanium dioxide, 38.5% of heavy calcium carbonate and 0.1% of hydroxyethyl cellul...

Embodiment 2

[0050] The difference between embodiment 2 and embodiment 1 is that the weight ratio of each component changes. This kind of environment-friendly water-based road paint mainly includes the following components according to weight percentage: deionized water: 1.6%; hydroxyethyl cellulose Ammonia: 0.2%; Photocatalyst slurry: 8%; Dispersant: 0.5%; Acrylic emulsion: 33%; Wetting agent: 0.2%; Heavy calcium carbonate: 39.5%; Rutile titanium dioxide: 7% ; Defoamer: 0.4%; Film-forming aid: 1.5%; Diatomaceous earth: 8%. The defoamer in the above composition is BYK-022 defoamer, and the film-forming aid is alcohol ester-12 solvent.

[0051] The above composition according to figure 1 The technological process shown is prepared, and it mainly comprises the following steps:

[0052] Step f: Weigh the raw materials according to the weight ratio of the above composition, add 10% acrylic emulsion, 0.5% dispersant, 0.2% wetting agent and 0.3% defoamer in sequence, stir at low speed for 5-10...

Embodiment 3

[0062] The difference between embodiment 3 and embodiment 1 and embodiment 2 is that the weight ratio of each component changes. This kind of environment-friendly water-based road paint mainly includes the following components according to weight percentage: deionized water: 1.6%; Ethyl cellulose: 0.1%; ammonia water: 0.2%; photocatalyst slurry: 15%; dispersant: 0.5%; acrylic emulsion: 33%; wetting agent: 0.2%; heavy calcium carbonate: 37.5%; rutile titanium White powder: 7%; defoamer: 0.4%; film-forming aid: 1.5%; diatomaceous earth: 3%. The defoamer in the above composition is BYK-022 defoamer, and the film-forming aid is TEXANOL solvent.

[0063] The above composition according to figure 1 The technological process shown is prepared, and it mainly comprises the following steps:

[0064] Step k: Weigh the raw materials according to the weight ratio of the above composition, add 10% of acrylic emulsion, 0.5% of dispersant, 0.2% of wetting agent and 0.3% of defoamer in seque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com