Dechlorination method of oil product or gas

A technology for dechlorination and oil products, applied in the petroleum industry, refining hydrocarbon oil, refining with metal oxides, etc., can solve problems such as equipment corrosion, failure to meet environmental protection standards, and decline in catalyst chlorine holding capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0030] A dechlorination agent suitable for dechlorination of reforming pre-hydrogenated oil is prepared.

[0031] Take Ca(OH) with particle size less than 149μm 2 and pseudo-boehmite (produced by Shandong Aluminum Factory, with an alumina content of 69% by mass), according to Ca(OH) 2 : the mass ratio of pseudo-boehmite 60:20 mixes evenly, adding the nitric acid (peptizer) that accounts for 34 mass % of the concentration of total material 3 mass %, accounts for the aluminum sol of total material 20 mass %, the solid content of aluminum sol is 30% by mass, then add an appropriate amount of water, knead into a ball in a kneader, extrude on an extruder and cut into pellets, dry at 110°C for 3 hours, and roast at 600°C for 4 hours to obtain dechlorination agent A, which contains calcium oxide 71% by mass and 29% by mass of alumina.

example 2

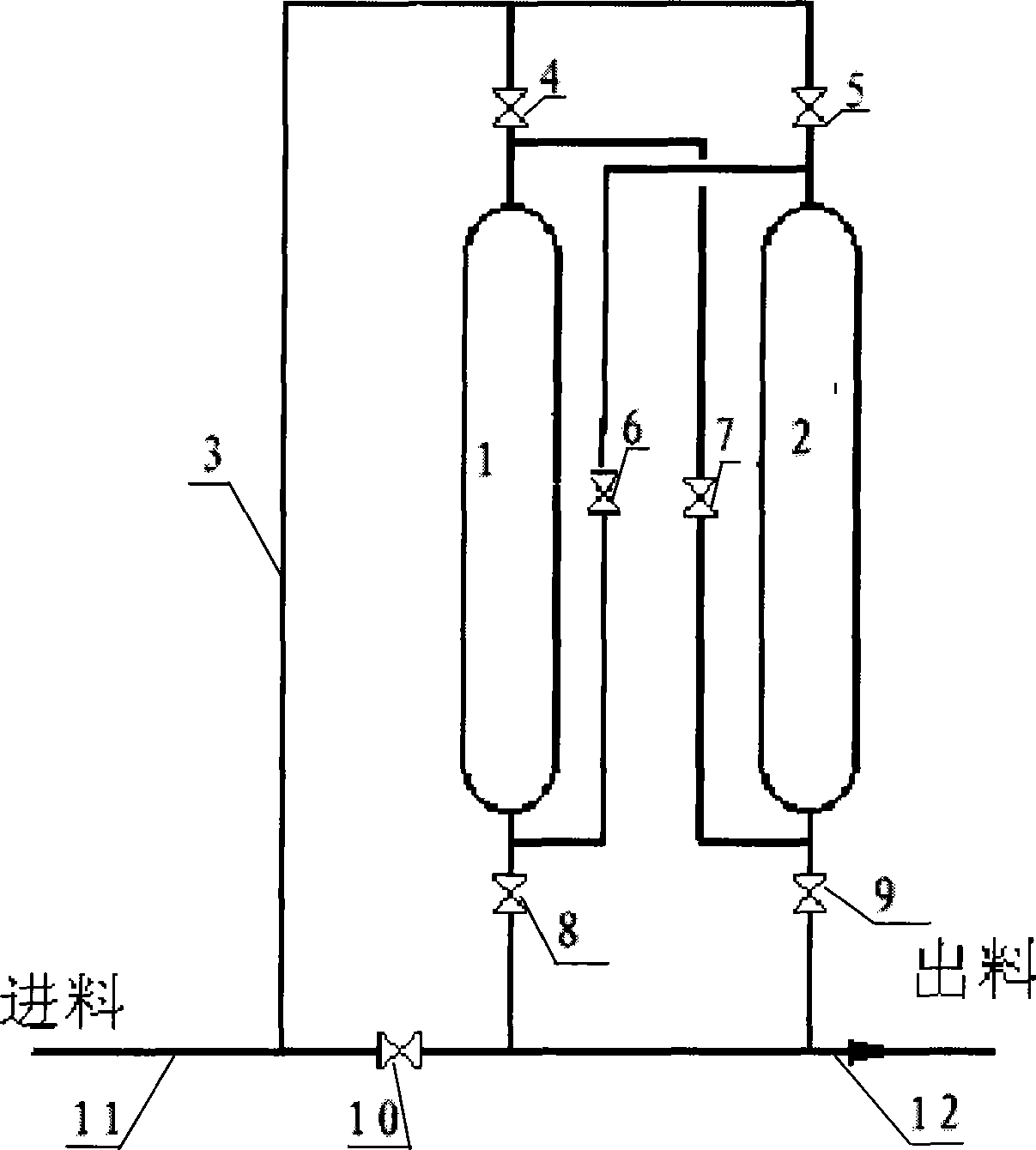

[0036] According to the method of the present invention, two dechlorination tanks are used to dechlorinate the reforming pre-hydrogenation oil.

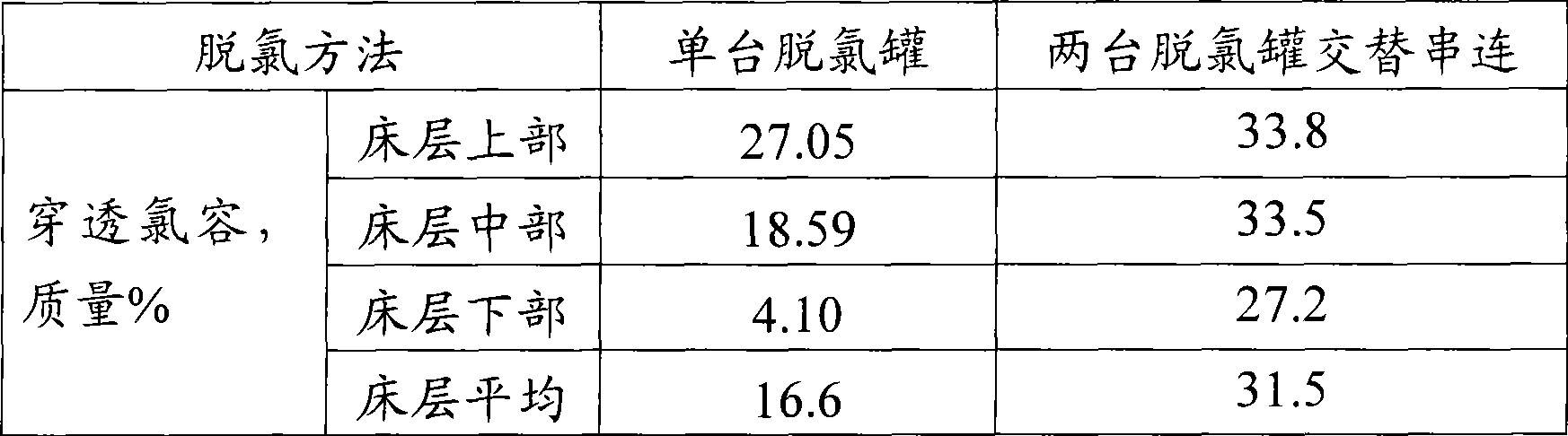

[0037] Each dechlorination tank is filled with 24g of dechlorination agent A, which is divided into three sections on average, separated by quartz glass filaments, and each section has a loading capacity of 8g. The heating method and conditions identical to Comparative Example 1 are used for dechlorination. A dechlorination tank 1 is first used for dechlorination, and when the dechlorination agent is penetrated, it is connected in series upstream of the second dechlorination tank 2 . Suspend the reaction when the second dechlorination tank dechlorination agent breaks through. The measured penetration chlorine capacity of dechlorination tank 1 is respectively: 38.64% by mass of the upper section, 37.77% by mass of the middle section, 36.87% by mass of the lower section, and an average of 37.74% by mass. The average value is close to t...

example 3

[0040] Preparation of dechlorinating agents suitable for reforming recycled hydrogen.

[0041] Get 40g of pseudo-boehmite (produced by Shandong Aluminum Works, with an alumina content of 69% by mass), 20g of clay and 40g of ZnO and mix evenly, add 4ml of nitric acid with a concentration of 65% by mass and 30ml of water for mixing. Extruded through a 2mm orifice, the extrudate was left standing at 20°C for 4 hours, dried at 120°C for 4 hours, and roasted at 450°C for 4 hours to obtain dechlorination agent B, which contained 31.5% by mass of alumina, 22.8% by mass clay and 45.7% by mass of ZnO.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com