Preparation method of oil soluble hydrogenation corrosion inhibitor for hydrogenation and reforming device

A reformer, oil-soluble technology, used in the treatment of equipment corrosion/fouling inhibition, petroleum industry, hydrocarbon oil treatment, etc., can solve the problems of poor film-forming performance of corrosion inhibitors, difficult to play anti-corrosion effect, and unsuitable to deal with emissions, etc. Achieve the effects of stable product performance, charge transfer and corrosive diffusion inhibition, and strong adaptability to corrosive environments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] Preparation of fatty acid aminoamide: Add the raw material fatty acid and polyamine in a molar ratio of 1:1.1 into the flask, stir, then add xylene while raising the temperature, reflux at 150-180°C for 2-4 hours, and release the generated water, until no water enters the water separator, and then continue to react for 1.5-1 hour, vacuum distillation, distilling xylene to obtain fatty acid aminoamide.

[0024] The preparation of table 1 fatty acid aminoamide

[0025]

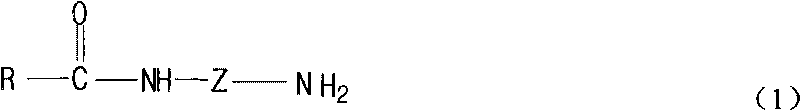

[0026] The structural formula of polyamine I is:

[0027]

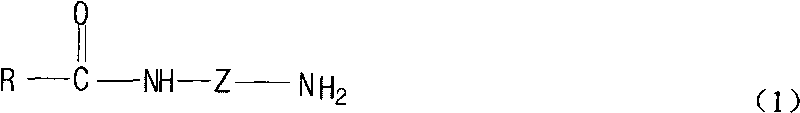

[0028] The structural formula of polyamine II is:

[0029]

Embodiment 1

[0030] Example 1: A hydrogenation corrosion inhibitor is formed by compounding 20% of diethylenetriamine, 10% of 2-ethylaminoheptadecenyl imidazoline, 30% of oleic acid aminoamide I and 40% of C10 heavy aromatics.

Embodiment 2

[0031] Embodiment 2: by dodecyl dimethyl tertiary amine 10%, 1-aminoethyl-2-tall oil base imidazoline 20%, oleic acid aminoamide II 20%, triphenyl phosphite 20% and C10 heavy aromatics compounded with 30% hydrogenated corrosion inhibitor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com