Color fixing process at high temperature of reactive dyes printing

A reactive dye and high-temperature color-fixing technology, which is applied in dyeing, heating/cooling fabrics, textiles, and papermaking, can solve the problems of reactive dye printing high-temperature color-fixing technology, and increase the coloring rate and color fastness of products , Improve production efficiency, high color fixing temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] 1. Selection of dyes: K-type reactive dyes have good applicability to this process.

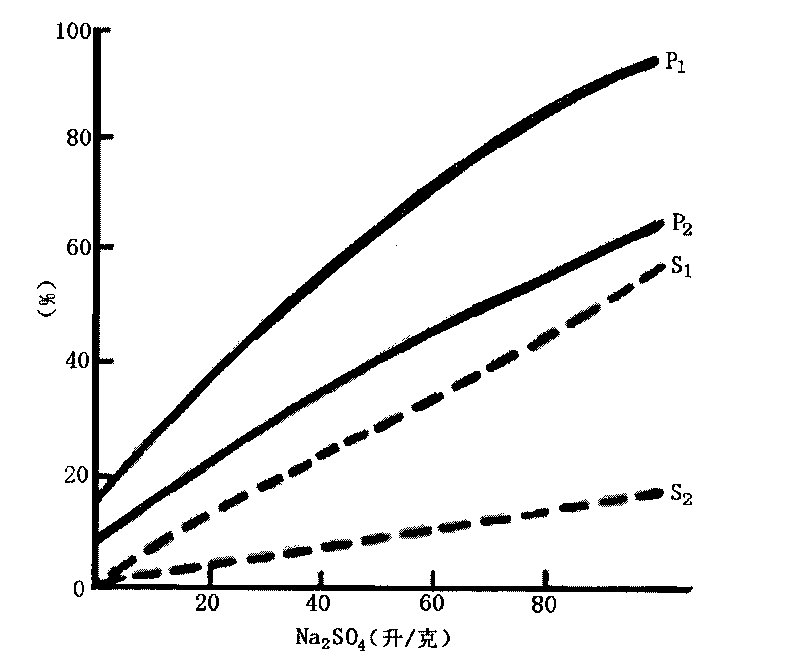

[0023] 2. Selection of padding aids: pretreat the pre-treated cloth before fabric printing, use soda ash, hygroscopic agent, yuanming powder substitute and whitening agent to pad and dry in the same bath, and when preparing the printing paste, do not Changing the formula of the color paste and the printing process, when the color is fixed at high temperature, due to the change of the surface of the fiber, the conditions for the interaction between the dye and the fiber have also changed, and the color fixing rate of the dye has been improved.

[0024] Padding liquid formula: ( / L)

[0025] Hygroscopic agent (using urea): 50g;

[0026] Soda ash: 20g;

[0027] Yuanming powder substitute: (using potassium chloride) 2.0g;

[0028] Whitening agent: (using VBL whitening agent) 1.5g;

[0029] The rest is water.

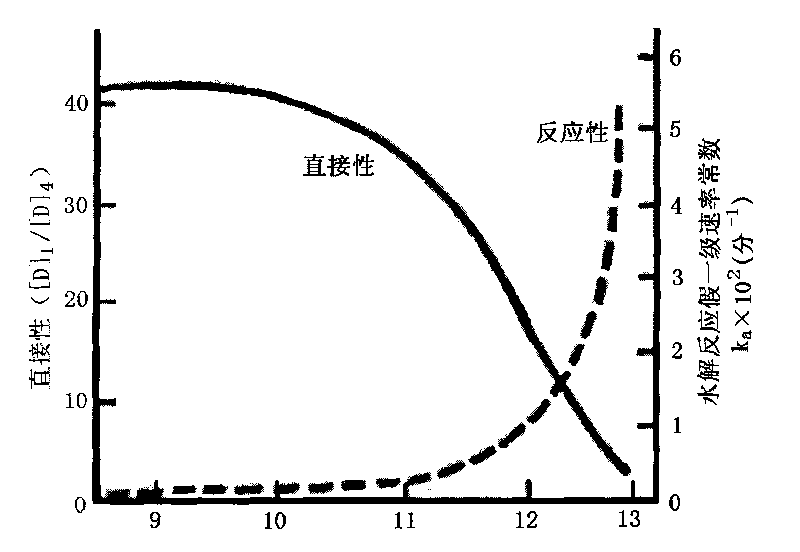

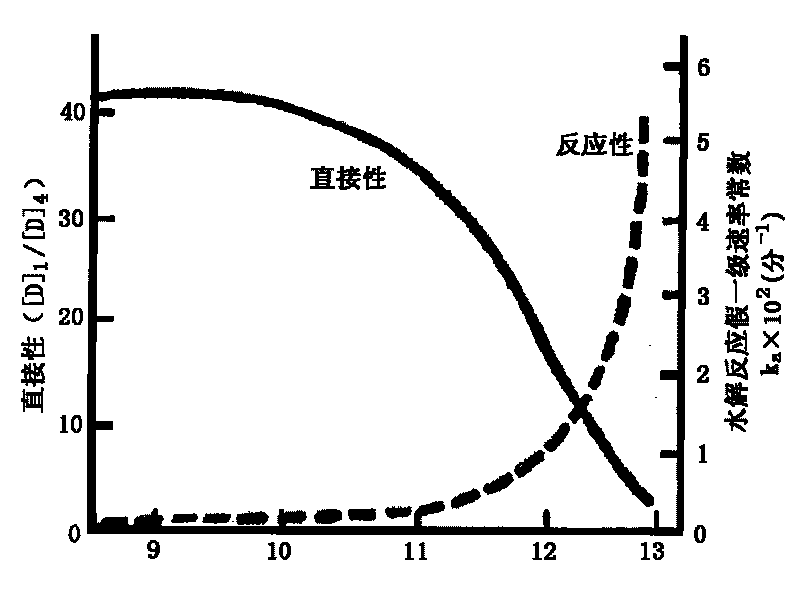

[0030] 3. Selection of process parameters: When K-type dyes are fixed at hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com