Toner, developer, developing device and image forming apparatus

A technology for toner and developer, which is applied in the direction of developer, electric recording process applying charge pattern, equipment of electric recording process applying charge pattern, etc. Reduced toner charge-to-mass ratio, adverse effects on fixability, and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

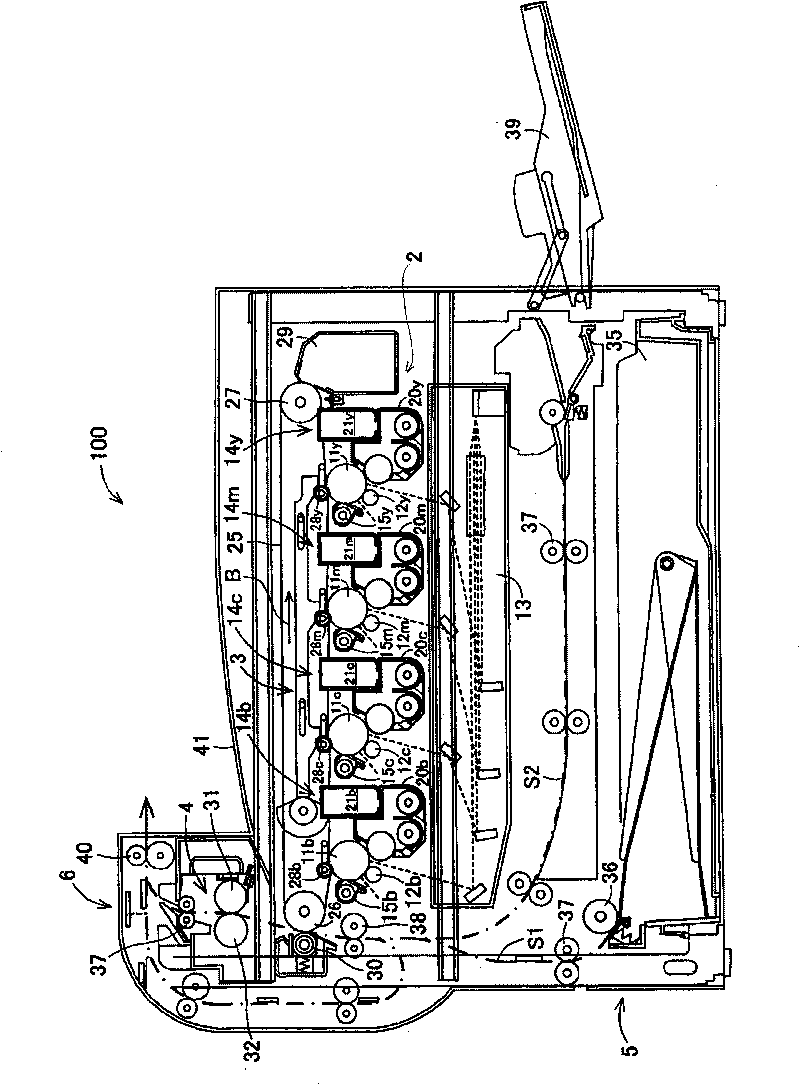

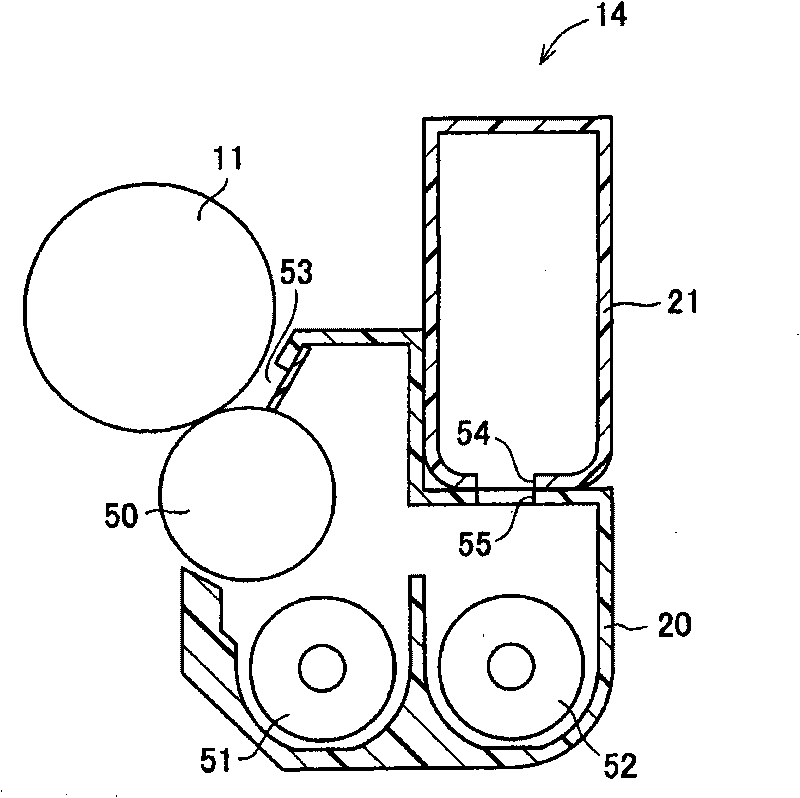

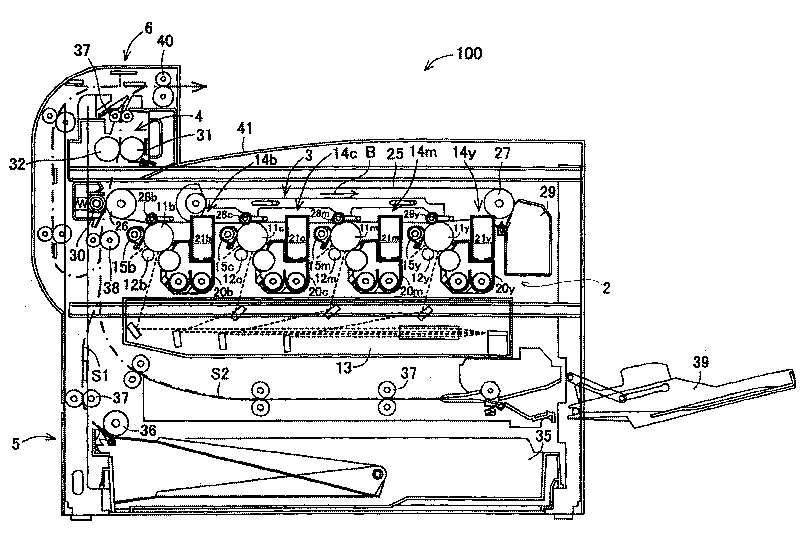

Image

Examples

Embodiment 1

[0241] To 100 parts by weight of the toner particles b, 1.45 parts by weight of silica fine particles (trade name: RX200, manufactured by Dyss Corporation) was added as inorganic fine particles, and 1.2 parts by weight of silica particles F were externally added to obtain Example 1 Toner.

Embodiment 2

[0243] Except that 1.6 parts by weight of silica particles G were added instead of silica particles F, the same procedure as in Example 1 was performed except that the toner of Example 2 was obtained.

Embodiment 3

[0245] Except that 2.0 parts by weight of silica particles H were added instead of silica particles F, the same procedure as in Example 1 was performed except that the toner of Example 3 was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com