Catalyst for catalyzing cellulose hydrolysis

A catalytic hydrolysis and catalyst technology, applied in the direction of physical/chemical process catalyst, catalyst activation/preparation, application, etc., to achieve high practical value, low price, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

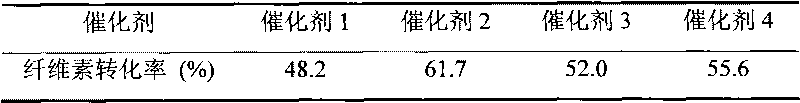

Embodiment 1

[0022] Add 5mmol (1.0417g) TEOS and 0.3mL concentrated nitric acid to 5mL absolute ethanol to prepare solution A; dissolve 0.5g P123 in 5mL absolute ethanol, stir at room temperature to form transparent solution B. Solution A was magnetically stirred at room temperature for 30 min, then slowly added to solution B, and magnetically stirred for 1 h. Finally, the mixed sol was poured into a petri dish and stored at room temperature of 40°C for 2 days. The obtained composite material was calcined in an air atmosphere at 400°C for 4h with a heating rate of 0.5°C / min. Finally, it is ground to 60-80 mesh to obtain the finished catalyst.

Embodiment 2

[0024] Add 6 mmol (1.2450 g) of TEOS and 0.3 mL of concentrated nitric acid to 5 mL of absolute ethanol to prepare solution A. The preparation process of other catalysts is the same as that of catalyst 1.

Embodiment 3

[0026] Add 7 mmol (1.4583 g) of TEOS and 0.6 mL of concentrated nitric acid to 5 mL of absolute ethanol to prepare solution A. The preparation process of other catalysts is the same as that of catalyst 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com