Method for preparing metal/titanium dioxide composite nano material at low temperature by gamma-irradiation

A composite nanomaterial and titanium dioxide technology, which is applied in the field of preparing metal/titanium dioxide composite nanomaterials, can solve the problems of low photocatalytic activity, difficulty in controlling particle size and morphology, poor product dispersibility, etc., and achieves high photocatalytic activity, Controllable morphology and stable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

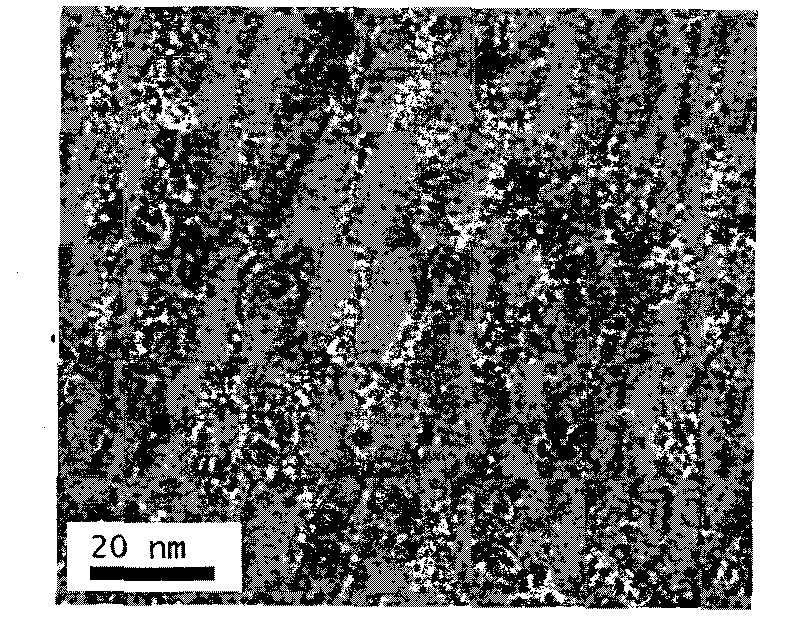

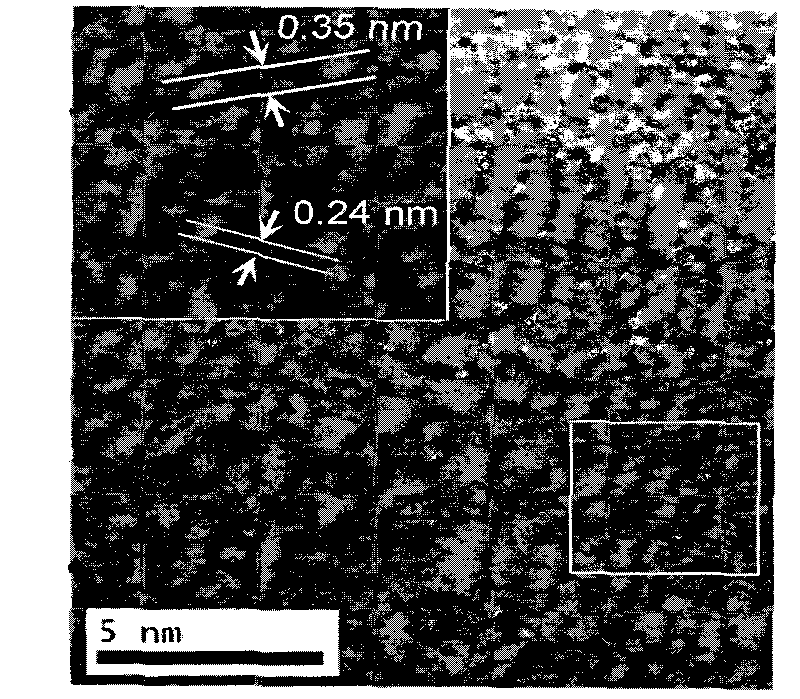

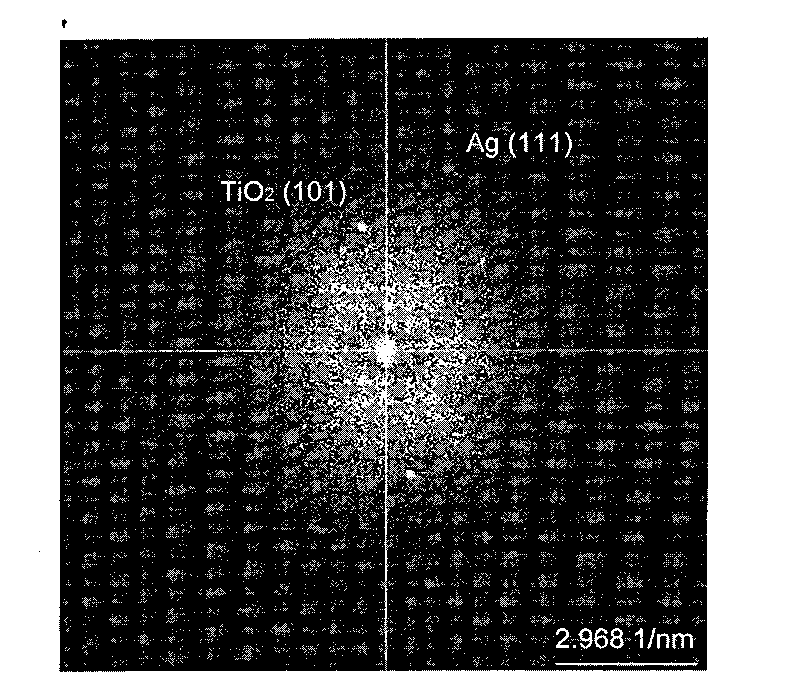

[0012] Specific embodiment 1: The method for preparing metal / titanium dioxide composite nanomaterials at low temperature by gamma-irradiation in this embodiment is carried out in the following steps: 1. Add the precursor of titanium to the alcohol, and prepare the concentration of the precursor of titanium to be 0.1-0.5 mol / L solution; 2. Take 10-50mL step 1 solution, add it dropwise to 10-50mL distilled water at room temperature under stirring condition, after the addition is completed, the water bath is heated to 60-80°C and continue stirring for 30-100min to obtain a slurry liquid; 3. The slurry liquid was separated by a centrifuge to obtain a precipitate, then added 50-300mL acid solution with a concentration of 0.05-5.0mol / L, sealed and stirred at 60-80°C for 4-20h, then added 100- 400mL distilled water to get TiO 2 Transparent sol; 4. Take 10-100mL TiO 2 For transparent sol, add 20-300μL of metal precursor solution with a concentration of 0.1-1mol / L and 3-20mL of isopr...

specific Embodiment approach 2

[0014] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in step 1, a solution with a titanium precursor concentration of 0.2-0.4 mol / L is prepared. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0015] Embodiment 3: This embodiment differs from Embodiment 1 in that in step 1, a solution with a titanium precursor concentration of 0.3 mol / L is prepared. Other steps and parameters are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com