Process for producing methionine

A technology of methionine and mother liquor, which is applied in the preparation of sulfide, chemical instruments and methods, and the preparation of organic compounds, can solve the problems of loss, inappropriateness, and high cost of liquid waste treatment, and achieve the effect of improving the filtration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

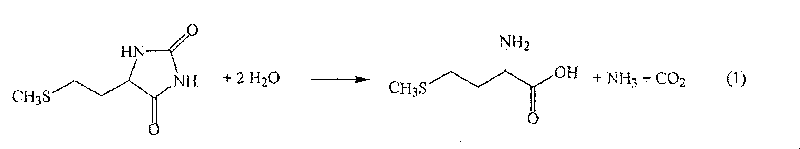

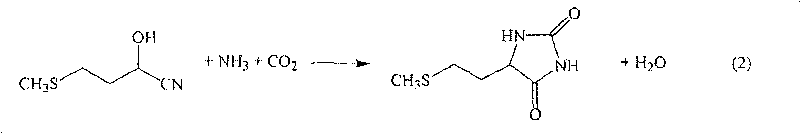

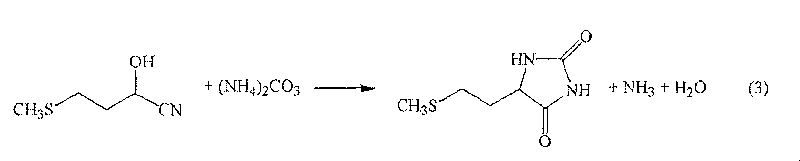

Method used

Image

Examples

Embodiment 1

[0053] [Reaction step (1)]

[0054] The hydrolysis reaction is carried out at a temperature of 173 to 178° C. for a residence time of 1 hour at a gauge pressure of 0.88 MPa under the condition that the following substances are introduced into the reactor: 5-[(2-( Methylthio) ethyl)] imidazolidine-2,4-dione aqueous solution (100 parts per hour), potassium hydroxide (1.0 parts per hour), the primary concentrated solution of the first crystallization mother liquor prepared separately (methyl sulfide amino acid concentration: 6.0%, and potassium concentration: 13.5%) (67.6 parts per hour), and the solution containing the second crystal (methionine concentration: 7.6%, and potassium concentration: 18.2%) prepared separately, that is, Concentrated solution of the second crystalline wet cake dissolved in the concentrated first crystalline mother liquor) (25.8 parts per hour).

[0055] [First crystallization step (2)]

[0056] The reaction solution (133.1 parts per hour) obtained by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com