Hydrophilic modifier for polyethylene films and preparation method thereof

A polyethylene film, hydrophilic technology, applied in the direction of coating, etc., can solve the problems of poor hydrophilicity, limited application field, low surface energy of polyethylene film, etc., to achieve the effect of not easy to be lost, firmly bonded, and improved hydrophilicity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

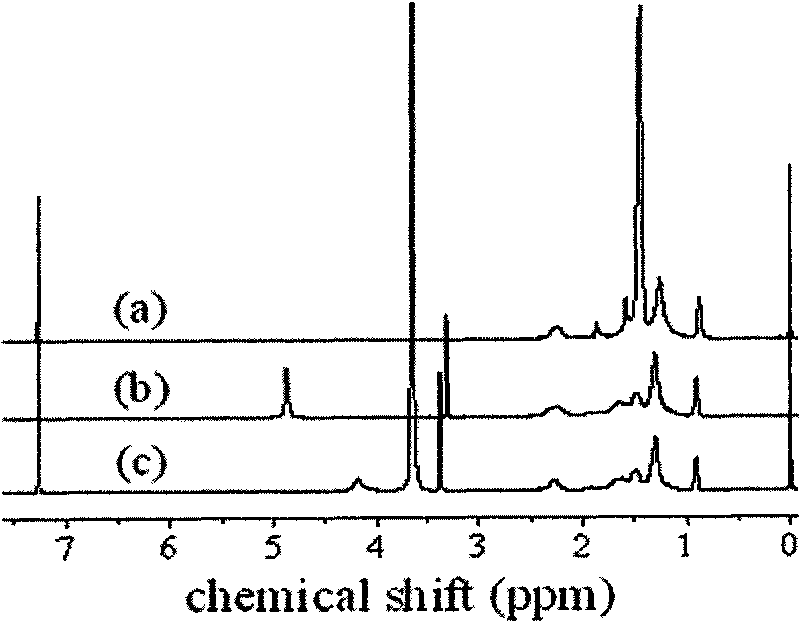

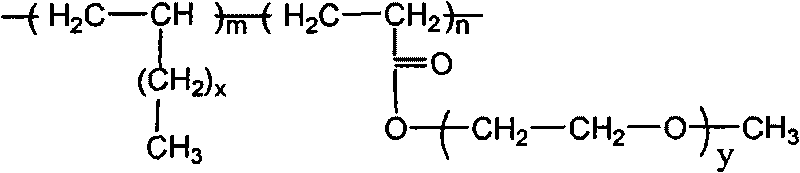

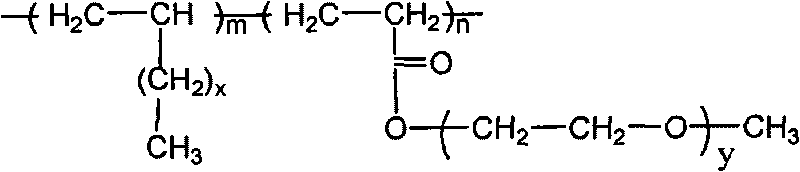

[0016] The flow process of preparing polyethylene film hydrophilic modifier of the present invention is shown in the following formula:

[0017]

[0018] m:n=37~1:63~99, m+n=19~572, x=5~17, y=7~44

[0019] The hydrophilic modifying agent for polyethylene film prepared by the present invention has a main chain of a random copolymer, and its composition can be controlled by adjusting the feed ratio of long-chain α-olefin and tert-butyl acrylate or changing the polymerization temperature. Controlling the content of the tert-butyl acrylate structural unit in the copolymer also controls the content of polyethylene glycol in the polyethylene film hydrophilic modifier.

Embodiment 1

[0022] Step 1) thoroughly remove oxygen and water in the reactor, 1-octene, tert-butyl acrylate and toluene, add 20 milliliters of toluene, 5.46 gram 1-octene and 2.08 gram tert-butyl acrylate successively, finally add 20 mg of Azodiisobutyronitrile initiates the polymerization. Polymerization was carried out at 80°C for 19 hours to obtain 2.16 g of a tert-butyl acrylate-1-octene copolymer. Proton nuclear magnetic resonance spectrum records that the molar percentage of tert-butyl acrylate structural unit in this copolymer is 74.8%, and the number-average molecular weight that records copolymer with gel chromatography is 7.5 * 10 3 g / mol, molecular weight distribution index 2.2.

[0023] Step 2) Dissolve 2 grams of the above-mentioned copolymer in 60 milliliters of tetrahydrofuran, add 4.35 milliliters of trifluoroacetic acid at room temperature, heat to reflux temperature, and reflux for 48 hours under stirring. The tert-butyl acrylate structural unit is completely hydrolyzed...

Embodiment 2

[0027] Step 1) thoroughly remove oxygen and water in the reactor, 1-octene, tert-butyl acrylate and toluene, add 20 milliliters of toluene, 5.46 grams of 1-octene and 2.08 gram of tert-butyl acrylate successively, finally add 15 mg of Azodiisobutyronitrile initiates the polymerization. Polymerization was carried out at 80°C for 19 hours to obtain 1.88 g of tert-butyl acrylate-1-octene copolymer. The molar percentage of tert-butyl acrylate structural unit in this copolymer is 76.2%, and number average molecular weight is 8.3 * 10 3 g / mol, the molecular weight distribution index is 1.9.

[0028] Step 2) Dissolve 1.8 grams of the above-mentioned copolymer in 60 milliliters of tetrahydrofuran, add 4.35 milliliters of trifluoroacetic acid at room temperature, heat to reflux temperature, and reflux for 48 hours under stirring. Acrylic acid-1-octene copolymer was obtained. The number average molecular weight of the copolymer is 6.1×10 3 g / mol, the molecular weight distribution in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com