Hybrid of dedoping-state polyaniline/metallic oxide

A technology of hybrids and polyaniline, applied in electrolytic capacitors, electrical components, circuits, etc., can solve the problems of difficult processing and no public reports on research, and achieve good oxidation/reduction reversibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

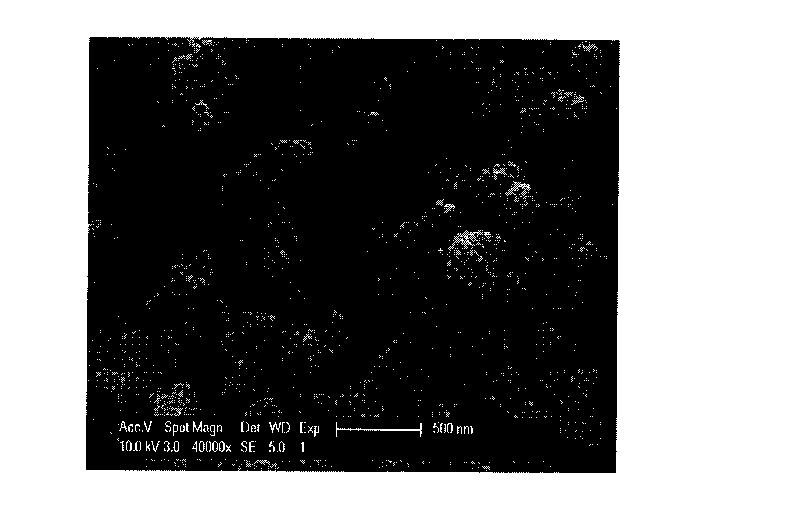

[0026] Put 1.2g of titanium sulfate in a reactor containing 80ml of deionized water and stir until completely dissolved; take 0.9ml of aniline and add it to the above salt solution; dissolved in 20ml of deionized water); followed by oxidative polymerization at 20°C for 6 hours without stirring, filtering, and washing the filter cake until neutral. Transfer the filter cake to a reactor, add 10w% ammonia water and stir at 20° C. for 24 hours; filter and wash the filter cake until neutral. Drying at 150° C. for 5 hours in an inert atmosphere to obtain a de-doped polyaniline / titanium oxide hybrid powder.

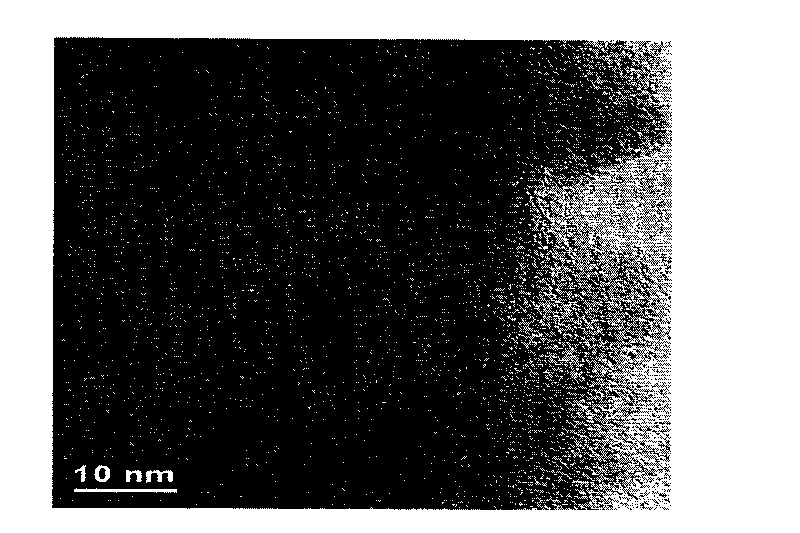

[0027] Energy spectrum analysis (EDS) proves that titanium, oxygen exists in the obtained product; FTIR (KBr) shows that there is a Ti-O-Ti bond (500cm -1 ~650cm -1 ). The content of titanium oxide in the hybrid is 15wt%-20wt%, and the two main thermogravimetric temperature ranges are: 400°C-450°C and 650°C-700°C. Electrochemical studies show that the hybrid is electrochemic...

Embodiment 2

[0029] Put 2.4g of titanium sulfate in a reactor containing 80ml of deionized water and stir until completely dissolved; take 0.9ml of aniline and add it to the above-mentioned salt solution; dissolved in 20ml of deionized water); followed by oxidative polymerization at 25°C for 3 hours without stirring, filtering, and washing the filter cake until neutral. Transfer the filter cake to a reactor, add 15 wt% ammonia water and stir at 25°C for 36 hours; filter and wash the filter cake until neutral. Drying for 3 hours under the condition of 180° C. in an inert atmosphere to obtain a de-doped polyaniline / titanium oxide hybrid powder.

[0030] Energy spectrum analysis (EDS) proves that titanium, oxygen exists in the obtained product; FTIR (KBr) shows that there is a Ti-O-Ti bond (500cm -1 ~650cm -1 ). The content of titanium oxide in the hybrid is 15wt%-20wt%, and the two main thermogravimetric temperature ranges are: 400°C-450°C and 650°C-700°C. Electrochemical studies show th...

Embodiment 3

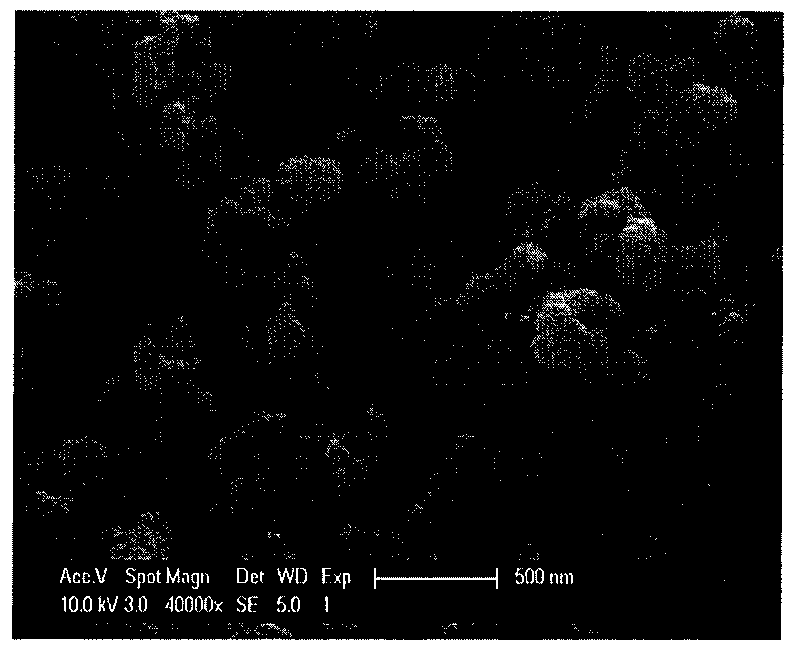

[0032] Place 7.2g of titanium sulfate in a reactor containing 80ml of deionized water and stir until completely dissolved; take 0.9ml of aniline and add it to the above-mentioned salt solution; dissolved in 20ml deionized water); then oxidatively polymerized at 20°C for 9 hours without stirring, filtered, and the filter cake was washed until neutral. Transfer the filter cake to a reactor, add 20 wt% ammonia water and stir for 48 hours at 20° C.; filter and wash the filter cake until neutral. Drying for 2 hours under the condition of 180° C. in an inert atmosphere to obtain a de-doped polyaniline / titanium oxide hybrid powder.

[0033] Energy spectrum analysis (EDS) proves that titanium, oxygen exists in the obtained product; FTIR (KBr) shows that there is a Ti-O-Ti bond (500cm -1 ~650cm -1 ). The content of titanium oxide in the hybrid is 15wt%-20wt%, and the two main thermogravimetric temperature ranges are: 400°C-450°C and 650°C-700°C. Electrochemical studies show that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com