Method for preparing functional grease by enzyme catalysis and modificaiton on tea oil

A functional, camellia oil technology, applied in the direction of fermentation, can solve the problems of modification and preparation, and achieve the effects of promoting the reaction, avoiding the influence of enzyme activity, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

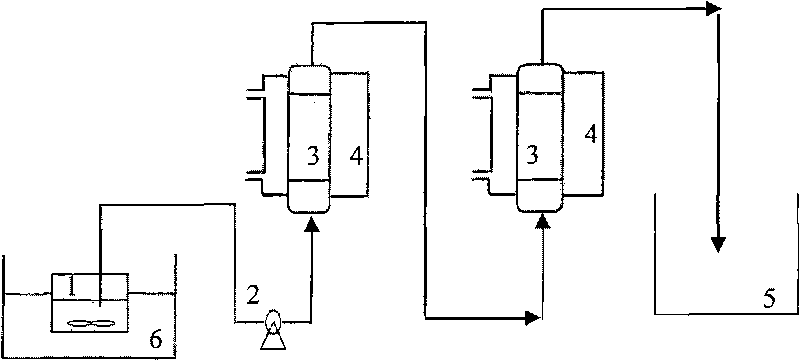

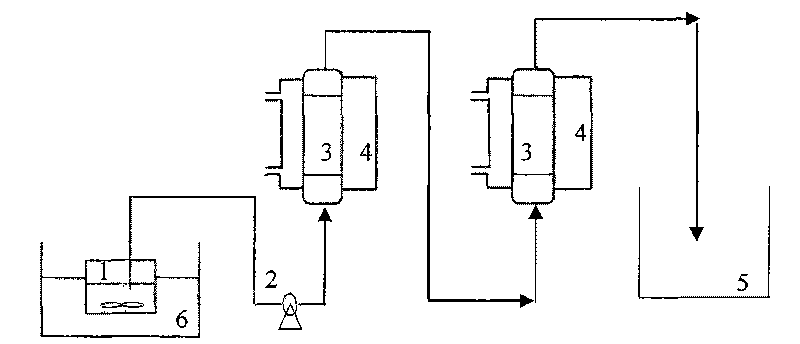

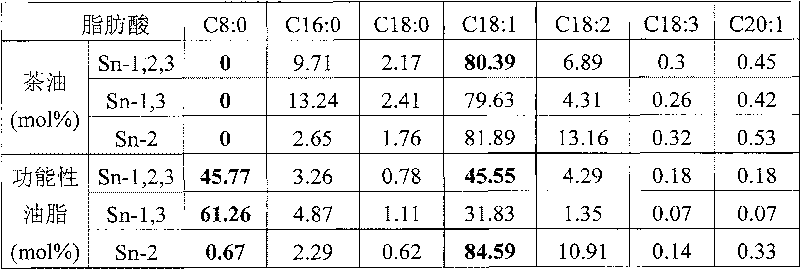

[0032] Put the tea oil and octanoic acid with a molar ratio of 1:4 into the raw material tank (with a stirring device), add 1.0% water of the raw material weight, and mix well to obtain the reaction substrate. Keep the substrate temperature at 60°C and 0.5ml / min The flow rate enters the product from the bottom of the reactor through a packed column enzyme reactor (inner diameter 2.6cm, outer diameter 4.2cm, enzyme filling height 18.5cm, and enzyme content 35g; temperature 60℃) equipped with Lipozyme RM (purchased from Novozyme). In the collection tank, the contact time between the substrate and the immobilized lipase is 2h, such as figure 1 Shown. The reaction product is separated by molecular distillation and free fatty acids are removed to obtain modified functional oil. The fatty acid composition (mol%) and fatty acid position distribution of the camellia oil raw material and functional oil are shown in Table 1.

[0033] The molar content of caprylic acid in the obtained func...

Embodiment 2

[0039] The operation steps are the same as in Example 1, except that the substrate passes through the packed column enzyme reactor at a flow rate of 1.5ml / min from the bottom of the reactor. The contact time between the substrate and the immobilized lipase is 0.7h, and the added water is the raw material weight. 0.5% of figure 1 Shown. The free fatty acid is removed from the reaction product to obtain functional grease, in which the molar content of caprylic acid is 39.57%. The life cycle of the immobilized enzyme exceeds 1.5 months.

Embodiment 3

[0041] The operating steps are the same as in Example 1, except that the molar ratio of tea oil to caprylic acid is 1:1, the added water is 0.1% of the weight of the raw material, the reaction temperature is 30°C, and the caprylic acid in the functional oil catalyzed by the tea oil enzyme The molar content is 23.03%. The life cycle of the immobilized enzyme exceeds 1.5 months.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com