Solid polymer electrolyte electrolytic bath

A solid polymer and electrolytic cell technology, applied in the field of electrolysis, can solve the problems of reduced catalyst utilization rate and unused catalyst, and achieve the effects of compact structure, simple processing and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

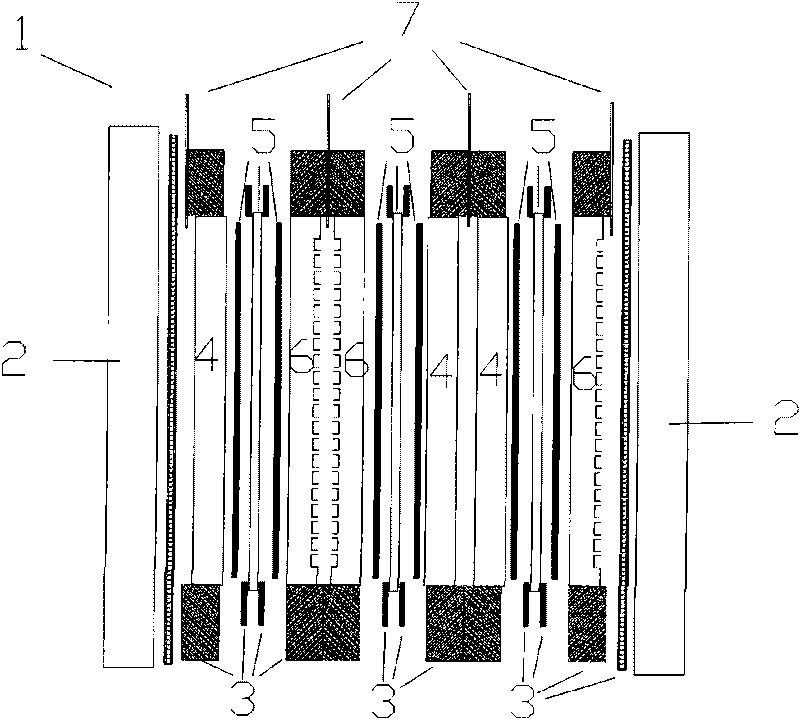

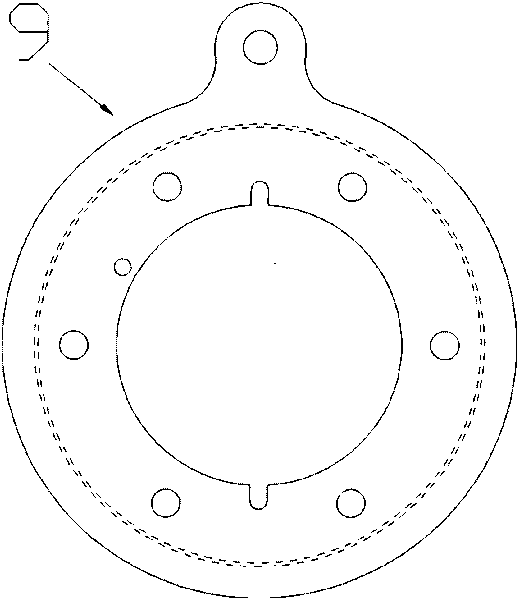

[0032] The SPE electrolytic cell structure of the present invention is mainly composed of two end plates [2], insulating material [3], cathode diffusion layer [4], MEA [5], anode integrated diffusion layer flow field [6], current collector [ 7] and so on. The anode diffusion layer is integrated with the flow field, and titanium powder is used as the base material, and the prepared mold is pressed under a certain temperature and pressure to obtain an integrated diffusion layer flow field. Two adjacent anodes or cathodes share a ring-shaped current collector, the current collector connected to the power supply cathode is in close contact with the two cathode diffusion layers [4], and the current collector connected to the power supply anode is in close contact with the two cathode diffusion layers [4]. The anode-integrated diffusion laminar flow field [6] is in close contact by means of pressure. MEA was prepared by spray method. The electrolytic cell is fastened with hexagon ...

Embodiment 2

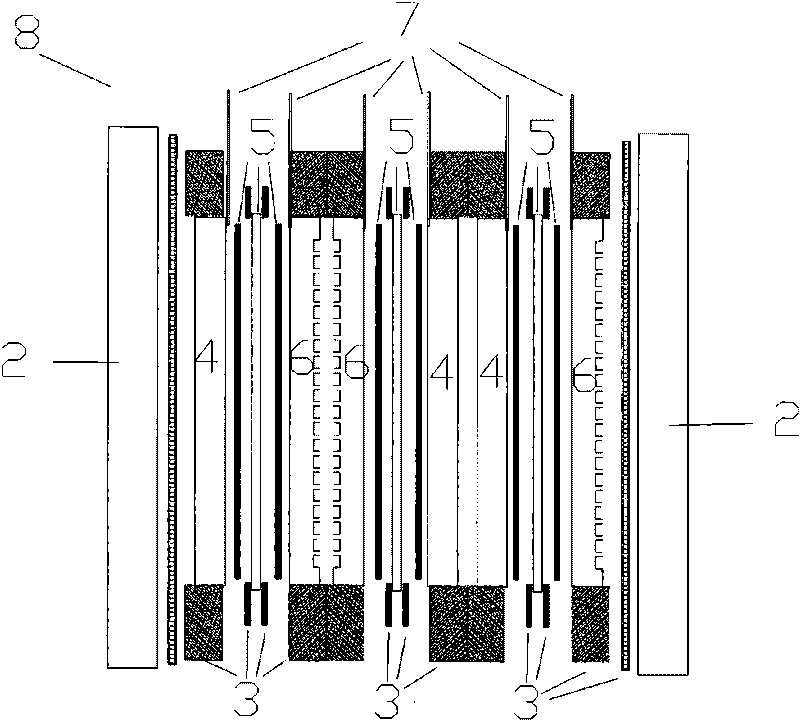

[0034] The SPE electrolytic cell structure of the present invention is mainly composed of two end plates [2], insulating material [3], cathode diffusion layer [4], MEA [5], anode integrated diffusion layer flow field [6], current collector [ 7] and so on. The anode diffusion layer is integrated with the flow field, and titanium powder is used as the base material, and the prepared mold is used for injection molding to obtain an integrated diffusion layer flow field. The current collector [7] connected with the power supply cathode is in close contact with the cathode diffusion layer [4] by means of pressing and sealing, and is sealed by insulating materials on both sides; the current collector connected with the power supply anode is connected with the anode diffusion layer and the flow field. The molds are in close contact with each other by pressing together to form the whole of the current collector and anode integrated diffusion layer flow field, and are sealed by insulati...

Embodiment 3

[0036] The SPE electrolytic cell structure of the first embodiment is adopted. A flow field with a certain groove-ridge ratio is processed on the anode diffusion layer by hot pressing with a die. Two adjacent anodes or cathodes share a ring-shaped current collector, and the ring-shaped current collector is placed between the two anode integrated diffusion layer flow fields [6] and connected by spot welding. Spot welding is used between the collector connected to the cathode of the power supply and the two cathode diffusion layers [4]. The MEA is prepared by chemical deposition method. The electrolytic cell is fastened with bolts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com