Axial flow fan

A technology of axial flow fan and shaft adjustment, which is applied in the direction of mechanical equipment, machine/engine, liquid fuel engine, etc. It can solve the problems of specification and quantity limitation, non-adjustable blade angle, and inability to adjust the blade working angle, etc., to achieve high strength and Toughness, the effect of avoiding fatigue fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

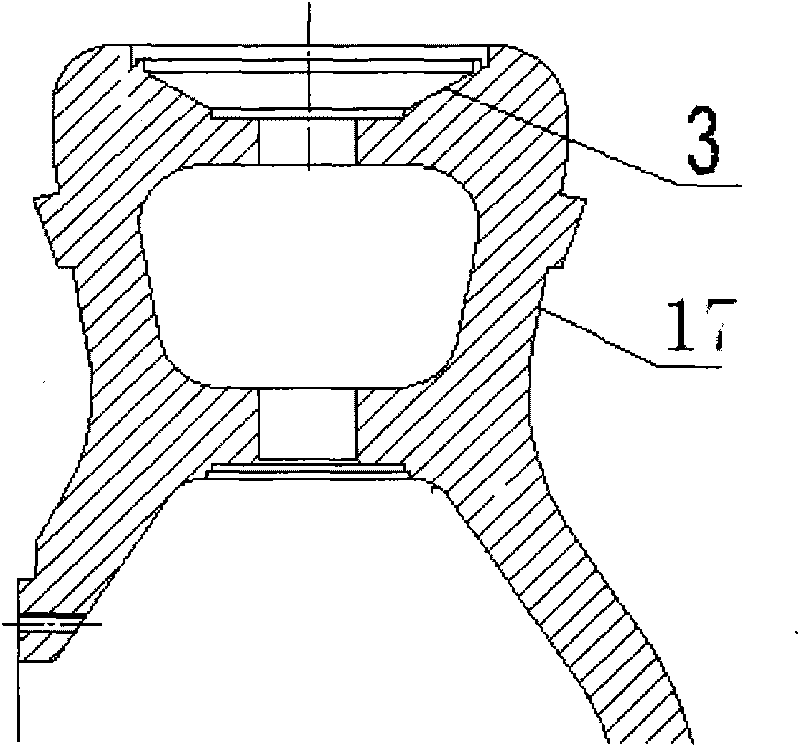

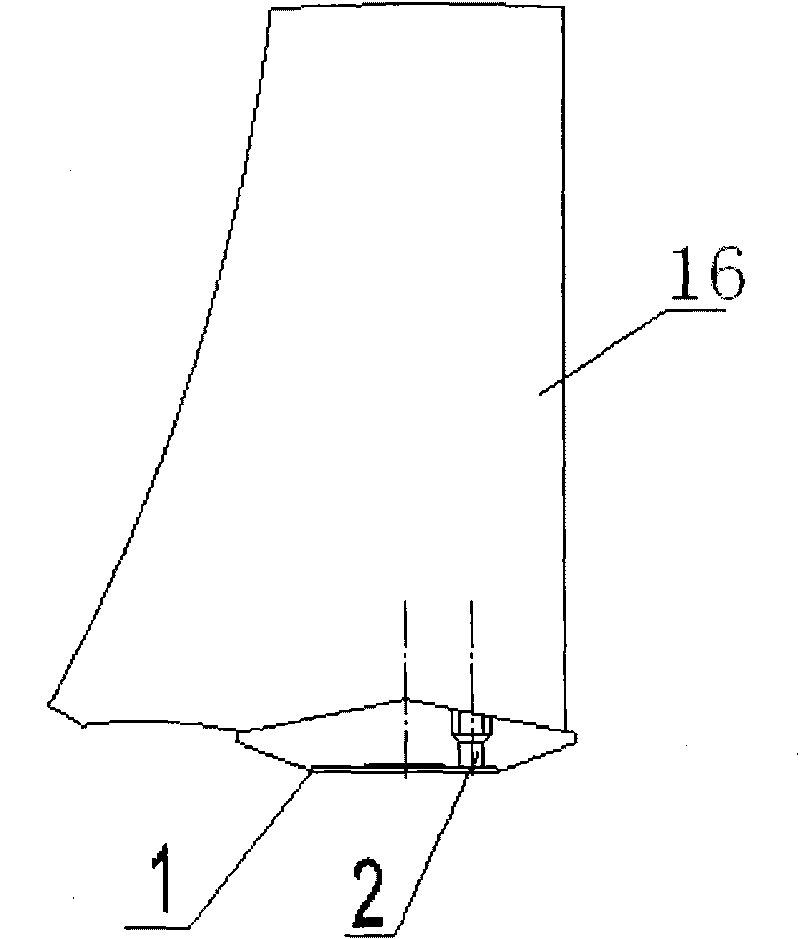

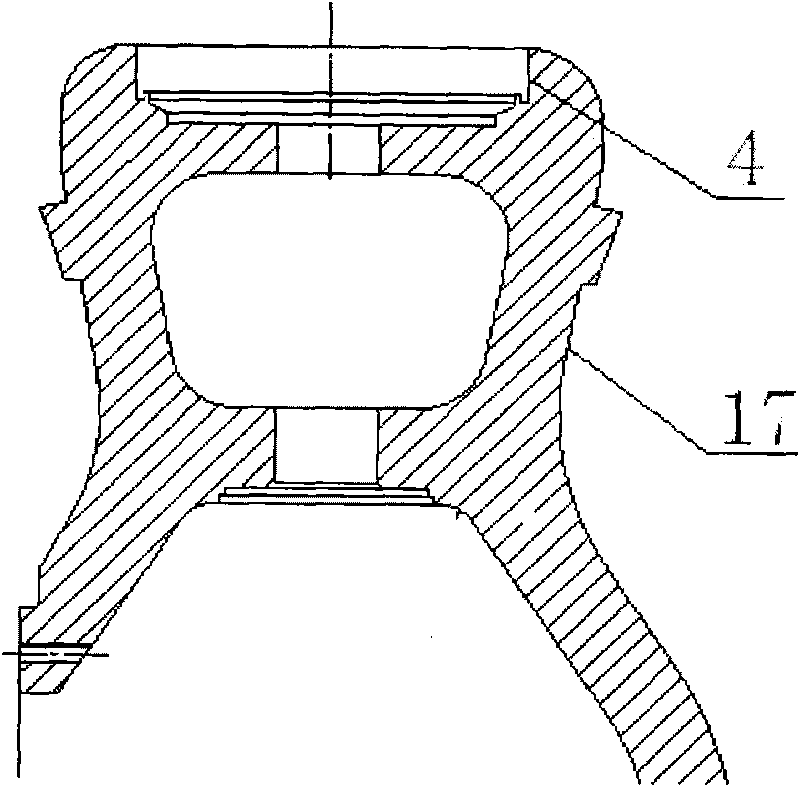

[0019] combine Figure 1 to Figure 4 As shown, the blade base hole 4 for installing the blade 16 on the hub 17 of the axial fan according to the present invention is an annular circular groove, and the blade base 5 is in the shape of a cylinder matching the annular groove. By changing the conical surface of the existing axial flow fan hub blade base hole 3 into a cylindrical surface, a larger space is reserved for the blade base 5, and the contact area of the part where the blade base 5 is connected with the petiole shaft disk 15 is larger, and the blade base The diameter of the bolt hole 6 that offers on 5 is bigger, and quantity is also more, can install more blade bolts 13, and the diameter of blade bolt 13 is also bigger. Therefore, by improving the connection between the blade 16 and the petiole shaft 14, the strength of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com