Method for removing photoresist and plasma processing equipment applying same

A technology of photoresist and process gas, which is applied in the field of microelectronics, can solve the problems of difficulty and damage in effectively and uniformly removing photoresist, so as to avoid damage to the surface of silicon wafers, remove evenly, and improve production efficiency and processing quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

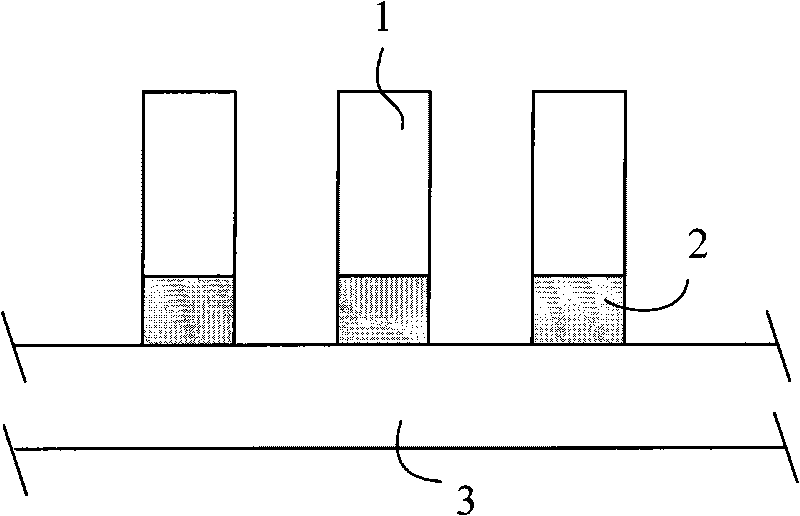

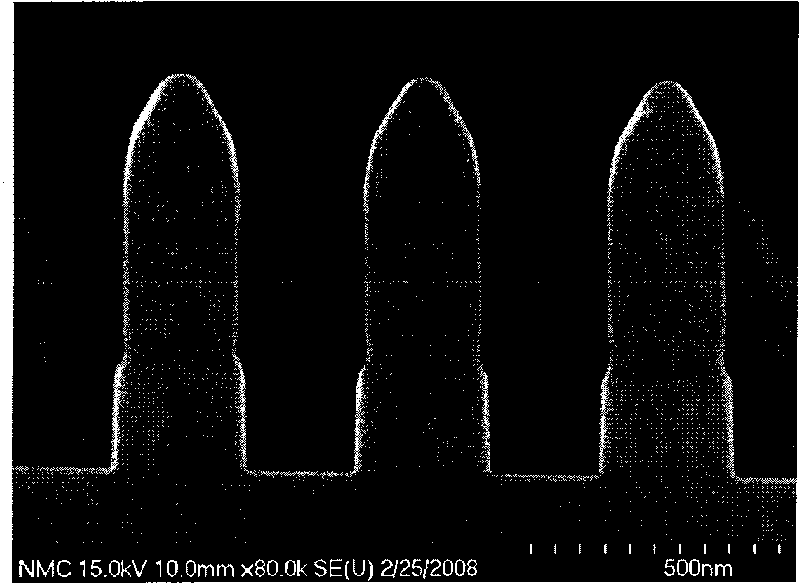

[0030] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the method for removing photoresist provided by the present invention and the plasma processing equipment applying the method will be described in detail below with reference to the accompanying drawings.

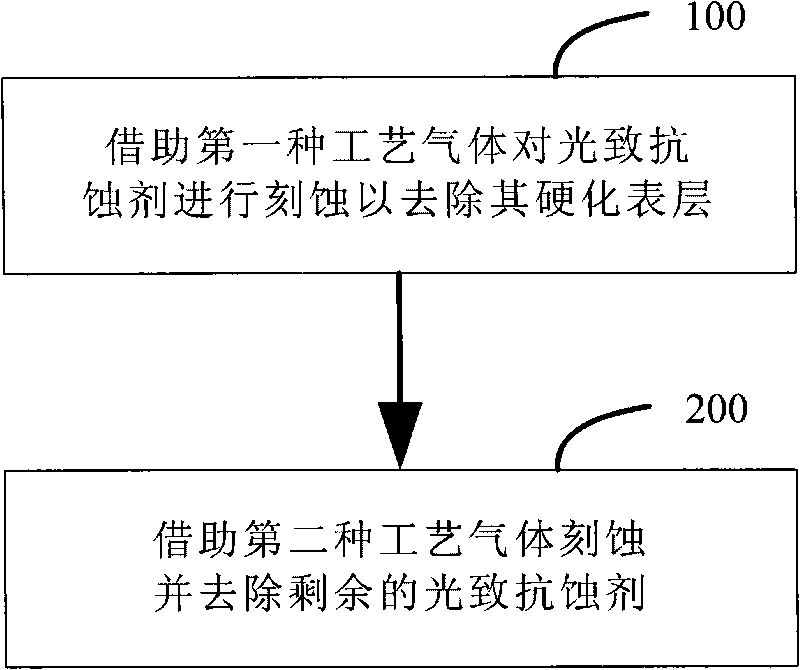

[0031] See figure 2 The method for removing photoresist provided by the present invention mainly includes the following steps:

[0032] 100) In the reaction chamber, the photoresist on the surface of the silicon wafer is etched with the aid of the first process gas, so as to remove at least the hardened layer on the photoresist.

[0033] 200) Continue to etch the photoresist with the aid of the second process gas to remove the remaining photoresist.

[0034] Wherein, the composition of the first process gas used in step 100) includes O 2 , CHxFy, N 2 , CO 2 Wait for the gas, here, O 2 And CHxFy is the main component, indispensable; and N 2 And CO 2 It can be add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com