Substrate modification-based method for preparing anisotropic organic field effect transistor

An anisotropic and organic field technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of uneven film performance, easy introduction of impurities, poor repeatability, etc., to achieve high uniformity and artificial High controllability and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

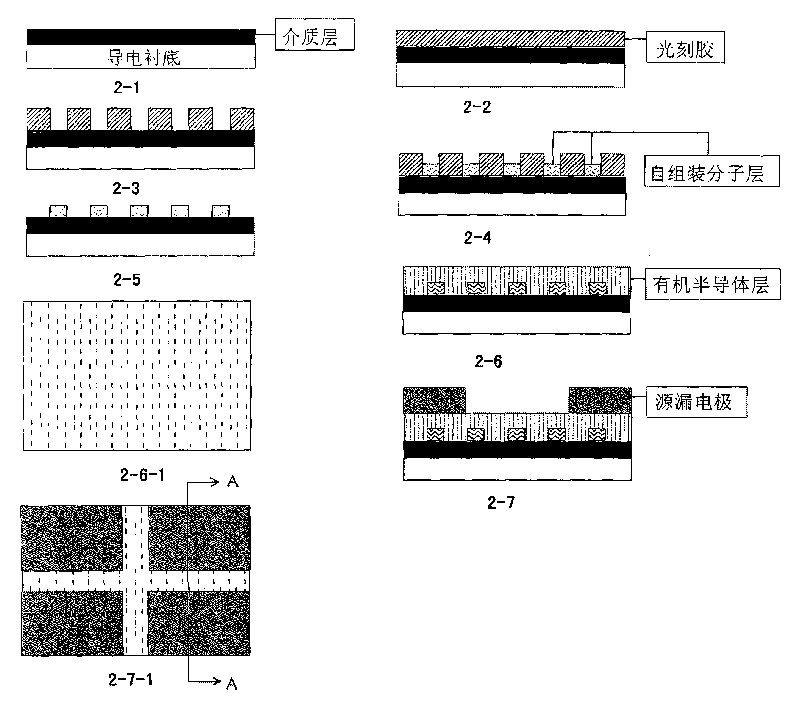

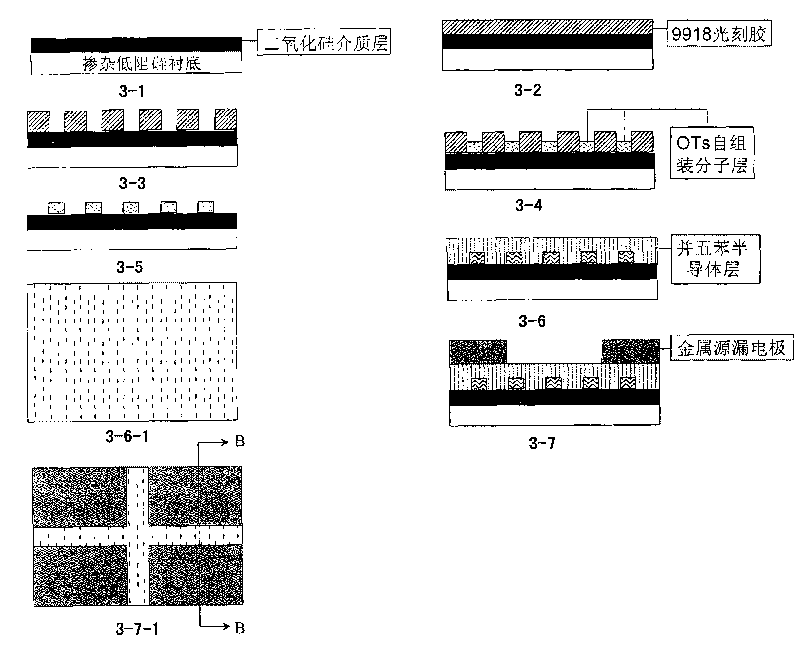

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

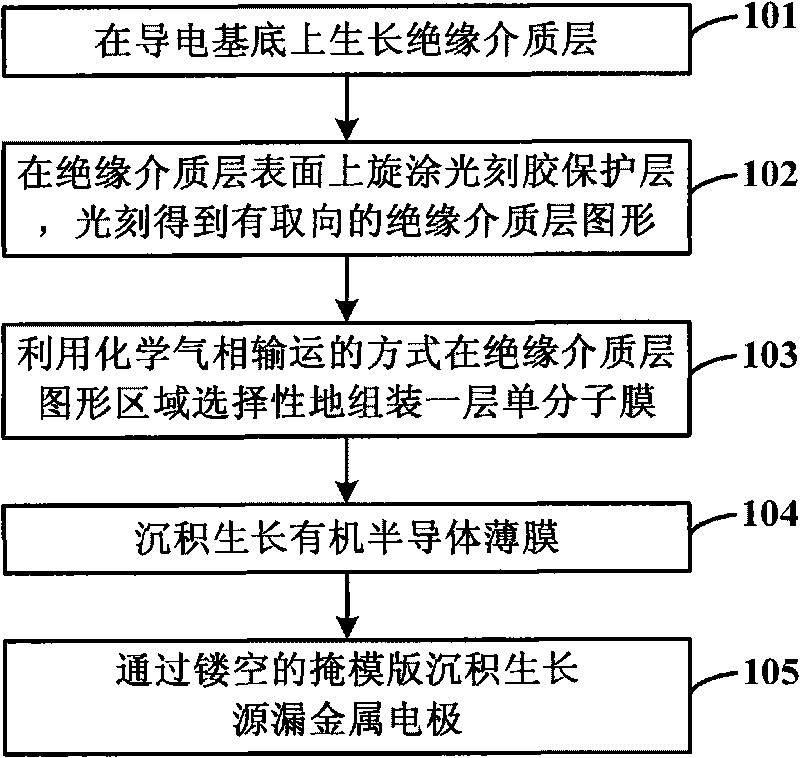

[0027] like figure 1 as shown, figure 1 It is a flowchart of the method for preparing an anisotropic organic field effect transistor based on substrate modification provided by the present invention. The method is to modify the substrate by one-time insulating medium layer growth, one-time photolithography, one-time monolayer molecular self-assembly, and one-time organic semiconductor thin film Growth and primary metal deposition to obtain an anisotropic organic field effect tube, specifically including the following steps:

[0028] Step 101: growing an insulating dielectric layer on a conductive substrate;

[0029] Step 102: Spin-coat a photoresist protective layer on the surface of the insulating dielectric layer, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com