Filter material and use thereof

A filter material, polytetrafluoroethylene technology, applied in the direction of filtration separation, dispersed particle filtration, dispersed particle separation, etc., can solve the problems of unusable and filter material failure, and achieve the effect of good collection efficiency and good mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

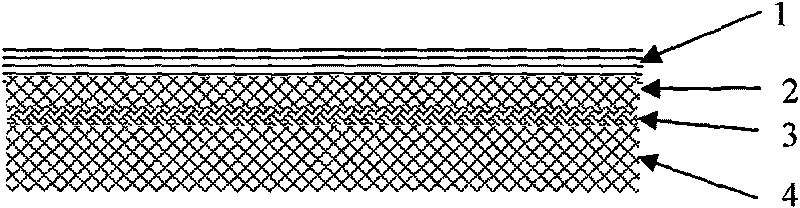

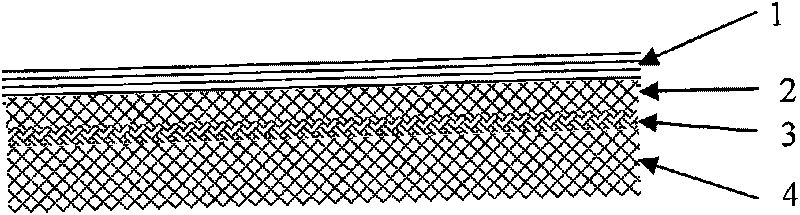

Image

Examples

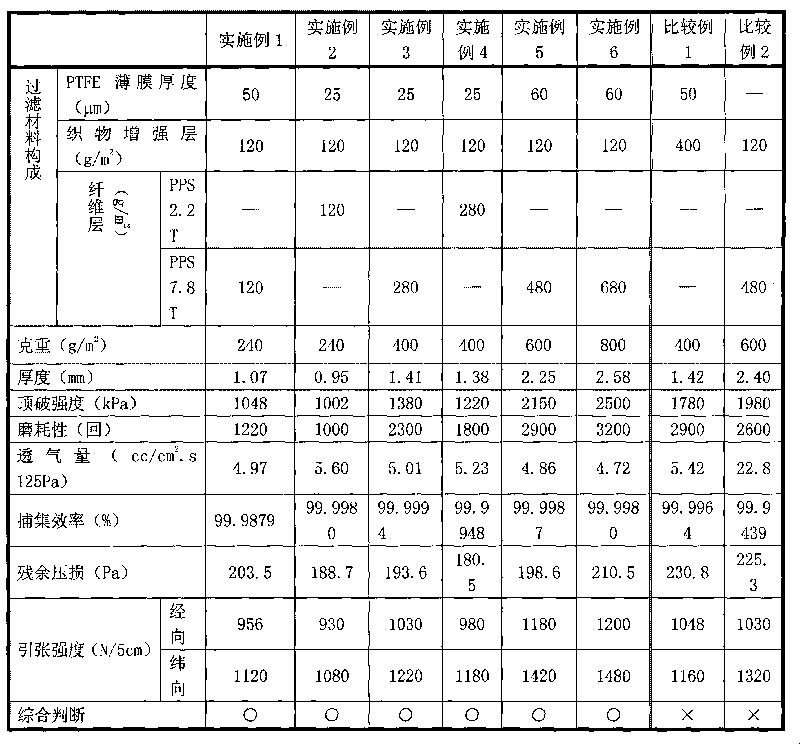

Embodiment 1

[0045] Warp 20S / 2 and weft 20S were obtained using PPS staple fibers with a fineness of 2.2 decitex (average fiber diameter 14.5 μm) and a piece length of 51 mm ("Tecon" manufactured by Toray Co., Ltd.). It was flat-woven to obtain a PPS staple fiber plain weave fabric with a warp density of 30 / 2.54 cm and a weft density of 14 / 2.54 cm. Using this fabric as the base fabric, use 120g / m on one side 2 The unit area weight of the laminated fiber web is made of PPS staple fibers with a denier of 7.8 decitex (average fiber diameter of 27.2 μm) and a length of 51 mm. 2 Obtained by needling, the web forms the fibrous layer of the filter material. Then the fabric (base cloth) and the above-mentioned fiber layer will be interwoven by further needle-punching, and the fibers of the fiber layer will pass through the fabric layer to form fiber needle-punched intertwining through the layer (i.e. the middle fiber layer) to obtain a grammage of 240g / m 2 , the total needling density is 300 pcs...

Embodiment 2

[0047] With the fabric described in embodiment 1 as the base cloth, on one of them with 120g / m 2 The unit area weight of the laminated fiber web is made of PPS staple fibers with a fineness of 2.2 dtex (average fiber diameter of 14.5 μm) and a length of 51 mm. 2 Obtained by needling, the web forms the fibrous layer of the filter material. Then the fabric (base cloth) and the above-mentioned fiber layer will be interwoven by further needle-punching, and the fibers of the fiber layer will pass through the fabric layer to form fiber needle-punched intertwining through the layer (i.e. the middle fiber layer) to obtain a grammage of 240g / m 2 , the total needling density is 300 pcs / cm 2 needle felt. Except for these, the filter material was obtained by the same method as Example 1.

Embodiment 3

[0049] With the fabric described in embodiment 1 as base cloth, on one of them face with 280g / m 2 The weight per unit area of the laminated fiber web is made of PPS staple fibers with a fineness of 7.8 decitex (average fiber diameter of 27.2 μm) and a length of 51 mm ("Tecon" S301-7.8T 51mm manufactured by Toray Co., Ltd.). After cotton and carding treatment, the needle density is 50 / cm 2 Obtained by needling, the web forms the fibrous layer of the filter material. Then the fabric (base cloth) and the above-mentioned fiber layer will be interwoven by further needle punching, and the fibers of the fiber layer will pass through the fabric layer to form fiber needle punching and intertwine through the layer (i.e. the middle fiber layer) to obtain a grammage of 400g / m 2 , the total needling density is 300 pcs / cm 2 needle felt. Except for these, the filter material was obtained by the same method as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com