Welding wire for connection of aluminum/steel dissimilar alloy and processing process thereof

A welding wire and heterogeneous technology, applied in metal processing equipment, welding medium, manufacturing tools, etc., can solve the problems of reducing joint performance and increasing the brittleness of aluminum/steel joints, so as to enhance fluidity, increase welding wire strength, and improve compound performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: A kind of welding wire used for aluminum / steel dissimilar alloy connection of the present invention, it is to take Al-Cu as matrix, add Ag, Mn, Mg, Ti, Zr, Zn element to develop, and this composition is by mass Percentage, containing Cu: 2.0% ~ 20.0%; Ag: 0.0% ~ 10.0%; Mn: 0.0% ~ 2.0%; Mg: 0.0% ~ 1.0%; Ti: 0.0% ~ 1.0%; Zr: 0.0% ~ 0.5% %; Zn: 0.0% to 0.5%; others are Al.

[0019] Described a kind of processing technology for the welding wire of aluminum / steel dissimilar alloy connection, steps are as follows:

[0020] (a) Material preparation: raw material: aluminum, purity ≥ 99.7%; master alloy: copper, silver, manganese, magnesium, titanium, zirconium, zinc and aluminum are first smelted into a master alloy, and the ingredients are prepared and added in the form of master alloy;

[0021] (b) Melting: preheat the crucible, put pure aluminum ingots into the crucible; after the aluminum is completely melted, add aluminum copper, aluminum silver, aluminum ma...

Embodiment 2

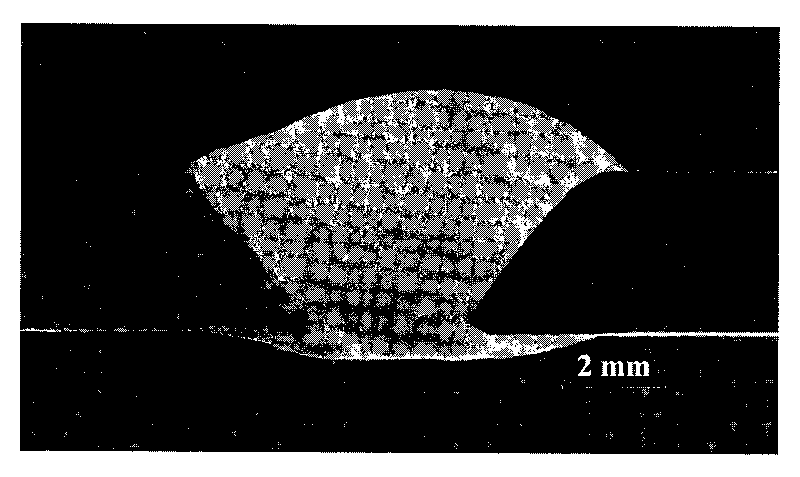

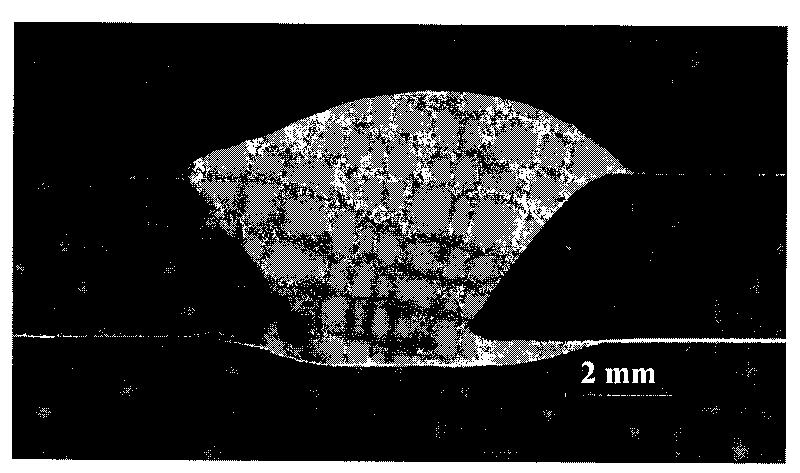

[0026] Example 2: Combining figure 1 , the invention is a welding wire for connecting aluminum / steel dissimilar alloys, the welding wire composition is Cu 5.5%-6.5%, Mn 0.2%-0.4%, Ti 0.1%-0.2%, Zr0.1%-0.2%, Zn 0.05 % ~ 0.1%, Al balance.

[0027] Using the welding wire with the above components, a well-formed aluminum alloy / stainless steel arc fusion-brazing butt joint was obtained, and the appearance of the joint is as follows figure 1 shown.

[0028] The welding wire composition is Cu 5.5%~6.5%, Ag 4.8%~5.8%, Mn 0.2%~0.4%, Mg 0.1%~0.2%, Ti 0.1%~0.2%, Zr 0.1%~0.2%, Zn 0.1%~0.2% %, Al balance.

[0029] The aluminum / steel dissimilar alloy TIG melting-brazing experiment was carried out with the above-mentioned welding wire, and the solder fluidity is good, the welding process is stable, and the joint is well formed.

[0030] The welding wire composition is Cu 9.8%-10.8%, Ag 3.0%-5.0%, Mn 0.5%-1.0%, Mg 0.1%-0.3%, Ti 0.3%-0.5%, Al balance.

[0031] The welding wire composition...

Embodiment 3

[0033] Embodiment 3: The purpose of the present invention is to overcome the above-mentioned defects of the welding wire and provide a new welding wire with better comprehensive performance. By adding some other special elements to replace the Si element, while ensuring the good fluidity of the solder, reduce the joint interface compound Layer brittleness.

[0034] The welding wire is developed with Al-Cu as the matrix, adding Ag, Mn, Mg, Ti, Zr, and Zn elements. The composition contains Cu: 2.0% to 20.0%; Ag: 0.0% to 10.0% by mass percentage. %; Mn: 0.0% to 2.0%; Mg: 0.0% to 1.0%; Ti: 0.0% to 1.0%; Zr: 0.0% to 0.5%; Zn: 0.0% to 0.5%; others are Al. The applicable aluminum and aluminum alloys of the present invention are all aluminum and its alloys; the applicable steels of the present invention are stainless steel, carbon steel, and alloy steel, especially stainless steel; the applicable welding methods of the present invention are arc welding and laser welding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com