Method for synthesizing silicon carbide nano wire by utilizing plant fiber

A technology of silicon carbide nanowires and a synthesis method, which is applied in the field of synthesizing silicon carbide nanowires, can solve the problems of complex production process, high production cost, unfriendly environment and the like, and achieves the effects of low cost, simple method and environmental friendliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

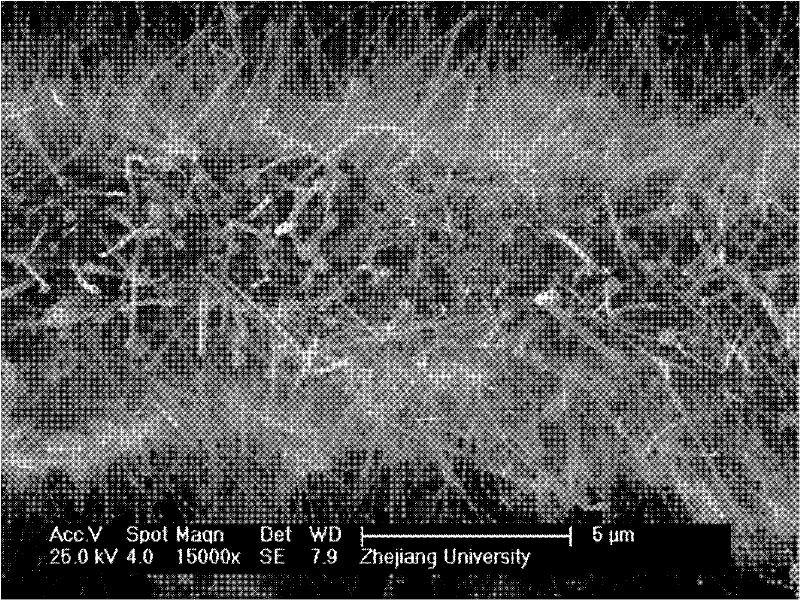

[0016] First, 0.7522g of iron nitrate nonahydrate, 0.1810g of silicon powder and 0.3878g of silicon dioxide powder were uniformly dispersed in 20ml of deionized water, stirred for 30 minutes, ultrasonically oscillated for 30 minutes, and then 0.1551g of purified hemp fiber was added. After soaking for 1 hour, the bamboo fiber is separated from the solution, and placed in an oven at 90° C. to dry it. The bamboo fiber after drying is placed in the high-temperature fixed-bed reaction furnace that temperature is 1200 ℃, feeds the argon gas that flow rate is 500sccm as shielding gas, obtains final product after reacting for 2 hours, is a large amount of silicon carbide nanowires (see figure 1 ).

Embodiment 2

[0018] First, 0.7144g of nickel nitrate hexahydrate and 0.3437g of silicon powder were uniformly dispersed in 20ml of deionized water, stirred for 30 minutes, ultrasonically oscillated for 30 minutes, and then 0.1473g of purified cotton fiber was added. After soaking for 2 hours, the cotton fibers were separated from the solution and dried in an oven at 90°C. Put the dried cotton fiber in a high-temperature fixed-bed reaction furnace with a temperature of 1200°C, and feed argon gas with a flow rate of 300 sccm as a protective gas. After reacting for 2 hours, the final product is obtained, and the appearance of the product is similar to figure 1 .

Embodiment 3

[0020] First, 0.403g of cobalt nitrate hexahydrate and 0.273g of silicon powder were uniformly dispersed in 20ml of deionized water, stirred for 45 minutes, ultrasonically oscillated for 45 minutes, and then 0.117g of purified poplar fiber was added. After soaking for 1.5 hours, the hardwood wood fiber is separated from the solution, and placed in an oven with a temperature of 90° C. to dry it. Place the dried hemp fiber in a high-temperature fixed-bed reaction furnace with a temperature of 1400 ° C, and feed in argon gas with a flow rate of 300 sccm as a protective gas. After reacting for 3 hours, the final product is obtained, and the appearance of the product is similar to figure 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com