Method for treating high-concentration organic industrial waste water and equipment thereof

A high-concentration technology for industrial wastewater, applied in water/sewage treatment, multi-stage water/sewage treatment, light water/sewage treatment, etc., can solve problems such as high investment costs, serious hazards, and fewer wastewater treatment devices, and achieve operational efficiency Low cost, high degree of automation, improved effect of purification treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

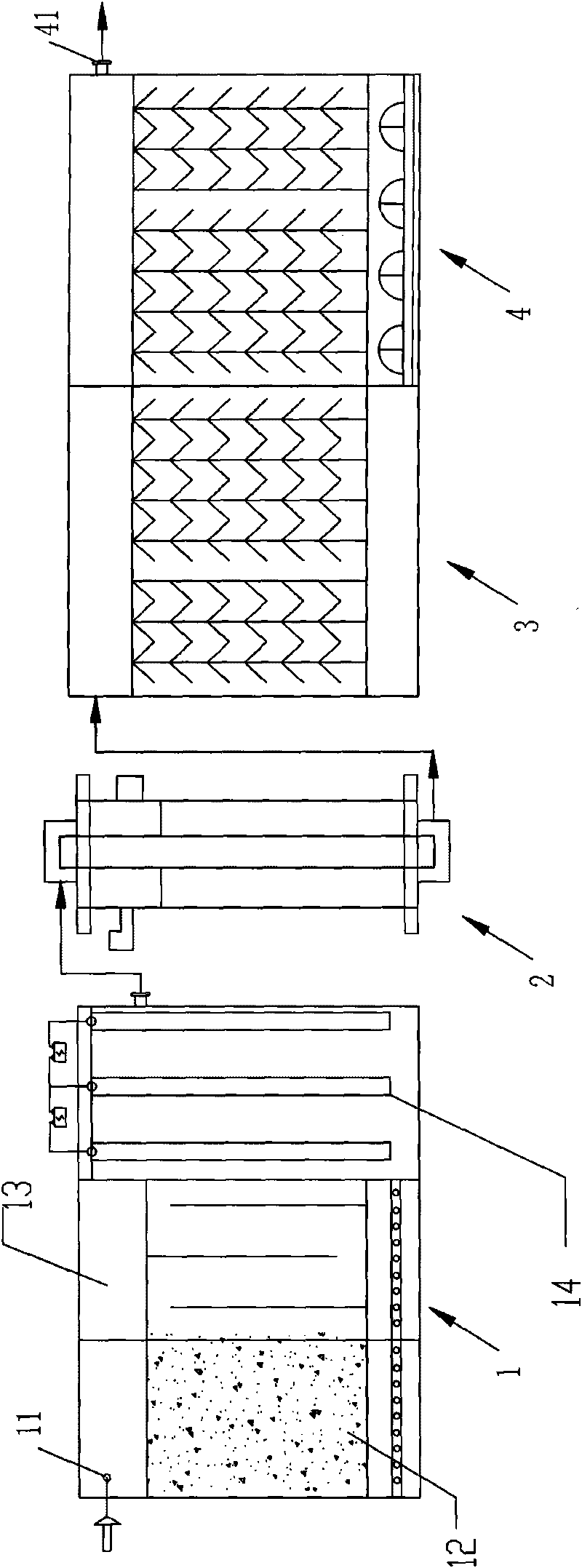

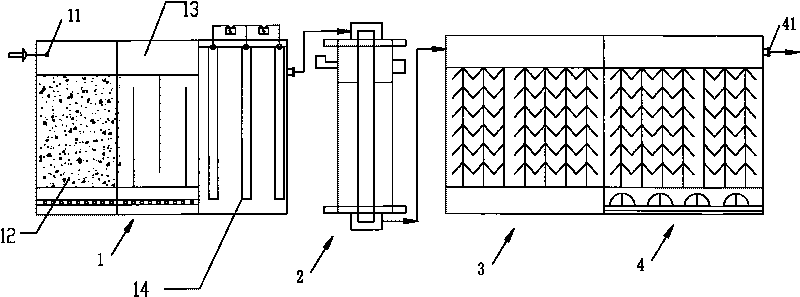

[0032] figure 1 It is a kind of high-concentration organic industrial waste water treatment equipment of the present invention, comprises rechargeable bed 1, photocatalytic oxidizer 2, hydrolytic acidification pond 3 and contact oxidation pond 4 that are connected sequentially in sequence, wherein, set on rechargeable bed 1 There is a waste water inlet 11, and a clean water outlet 41 is provided on the contact oxidation tank 4. When in use, the organic industrial wastewater is transported from the wastewater inlet 11 of the device to the wastewater treatment device, and then sequentially passed through the rechargeable bed 1, the photocatalytic oxidizer 2, the hydrolysis acidification tank 3 and the contact oxidation tank 4, from the net The water flowing out of the water outlet is clean water that meets environmental protection requirements, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com