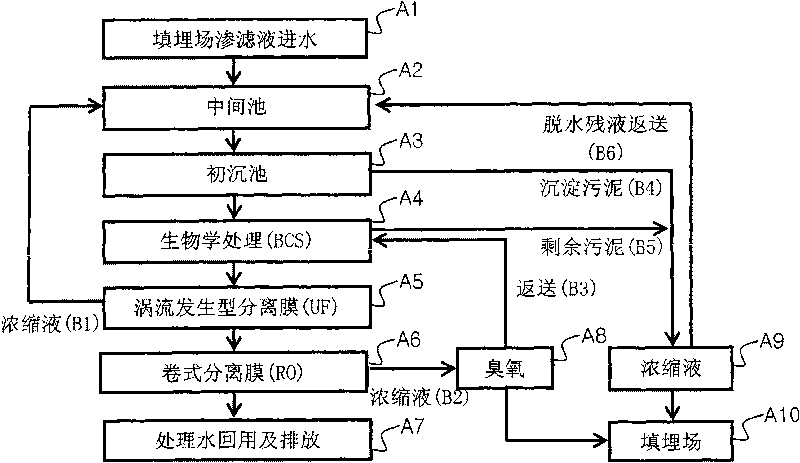

Treatment process of garbage percolate

A landfill leachate and treatment process technology, which is applied in the field of landfill leachate treatment process, can solve the problems of large area occupied by facilities, small gas-liquid contact area, and inability to effectively solve ammonia nitrogen treatment, etc., so as to reduce the occupied area and reduce the The effect of small facility footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, how to implement the technical solutions provided by the present invention will be further described in detail, and a non-limiting specific implementation manner of the present invention will be described in conjunction with the accompanying drawings.

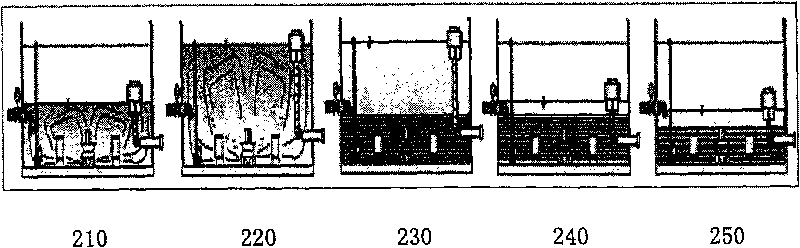

[0035] The vortex separation membrane device is used as the pretreatment device in the advanced treatment stage

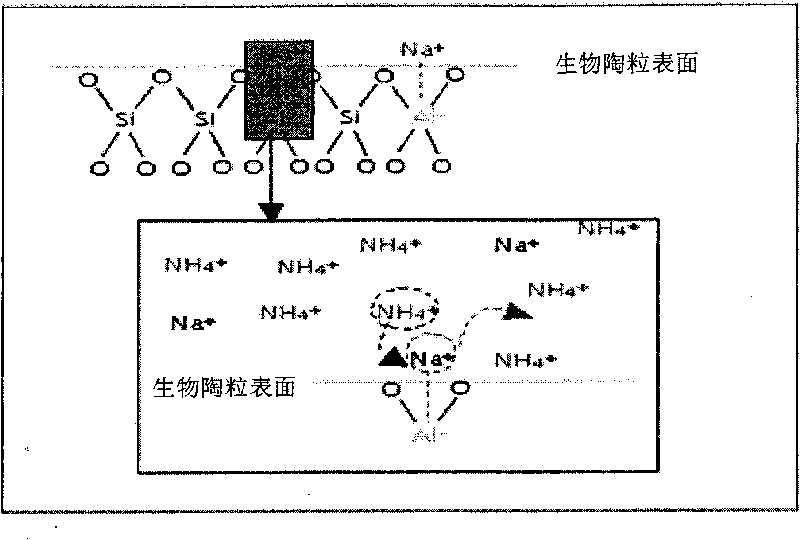

[0036]The roll-type separation membrane used in the leachate treatment process of the present invention is a reverse osmosis membrane, and the treatment liquid needs to be pretreated before entering the reverse osmosis membrane for treatment, so as to remove solids. In the present invention, a vortex separation membrane device is used as a pretreatment device, wherein the membrane module is in the form of a flat membrane structure, and a vortex-generating rotating blade is placed between the membranes. In the prior art, there is a device that adopts a cross flow method to increase the flow velo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com