Processing technique for comprehensive waste water of saponin-alcohol

A comprehensive wastewater and treatment process technology, which is applied in food industry wastewater treatment, natural water treatment, neutralized water/sewage treatment, etc., can solve the problems of high pollution load, poor biodegradability, high acidity, etc., and achieve high removal rate and high efficiency The effect of removing and prolonging the residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

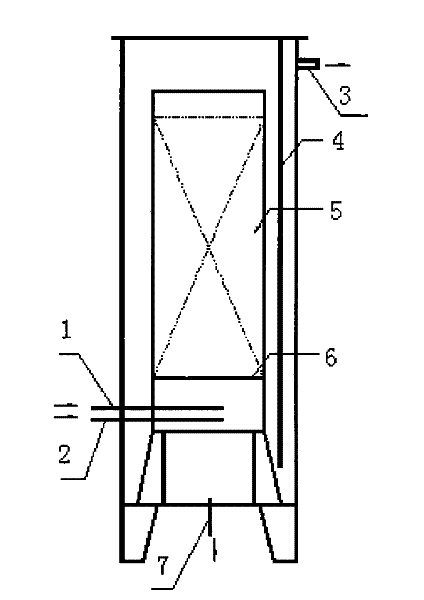

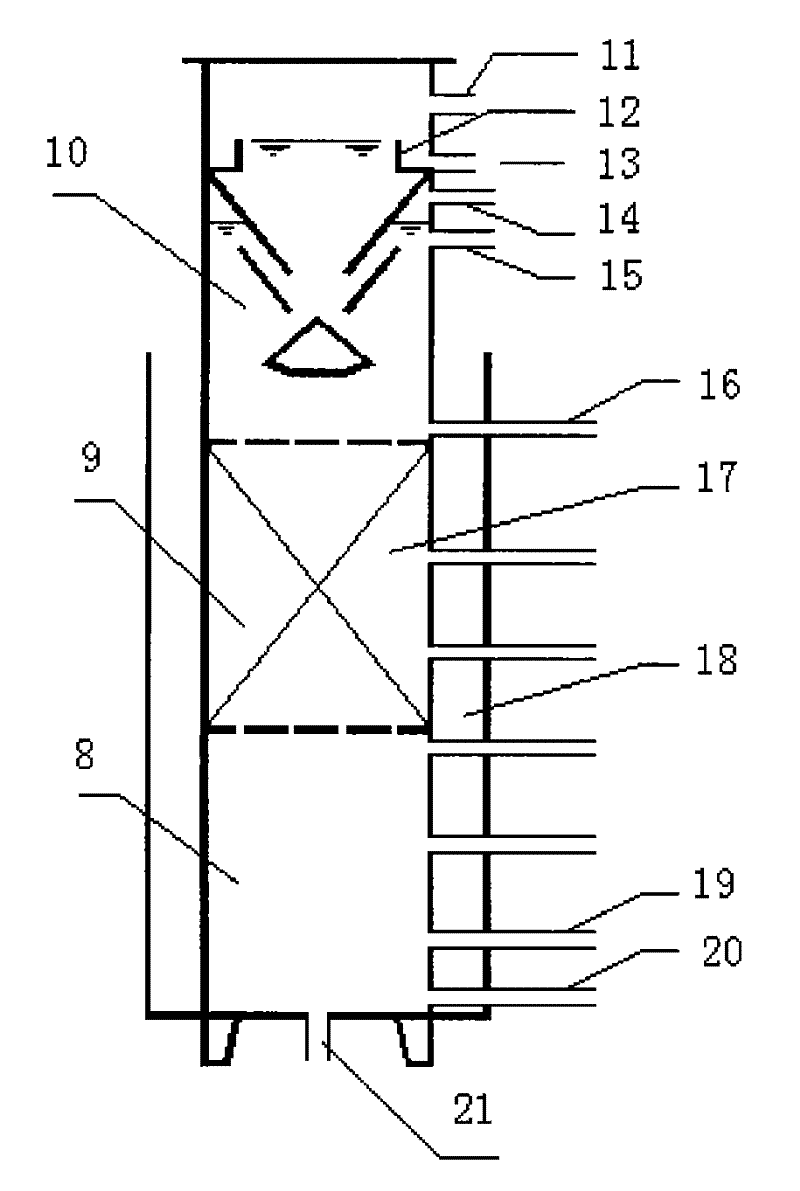

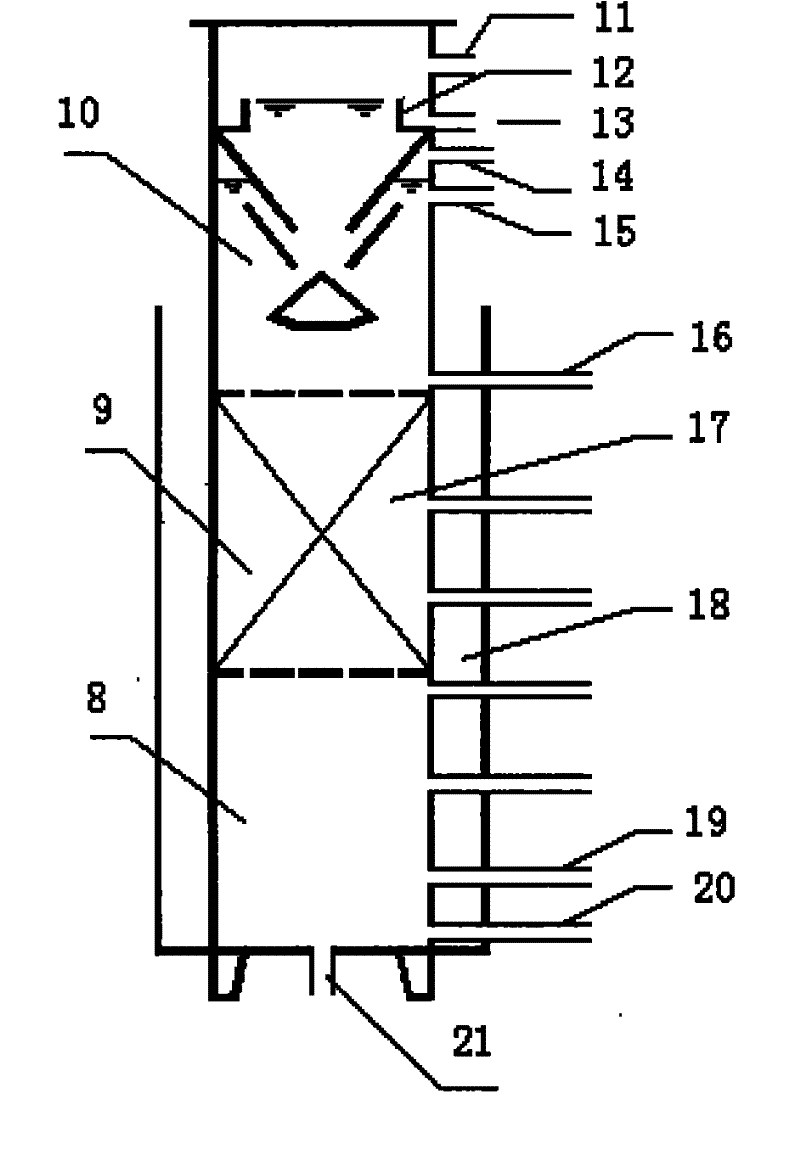

Method used

Image

Examples

Embodiment Construction

[0018] The treatment process of saponin-alcohol comprehensive waste water, it comprises the steps:

[0019] 1) Saponin-alcohol comprehensive wastewater (saponin-alcohol comprehensive wastewater is the final wastewater of turmeric saponin SMRH clean production process) is first discharged to the regulating tank, and after staying for 2 to 3 days, the sewage pump in the regulating tank is pumped into the first In the secondary pH adjustment sedimentation tank, quicklime powder is added to increase the pH value of the saponin-alcohol comprehensive wastewater to 5.0-6.5, and the comprehensive wastewater after adjusting the pH value is obtained; the comprehensive wastewater after adjusting the pH value is in the first pH adjustment sedimentation tank Stay in the sediment for 10-12 hours, react to form calcium sulfate precipitation to remove a large amount of sulfate radicals, and also remove harmful substances such as pectin in the comprehensive wastewater, and the COD removal rate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com