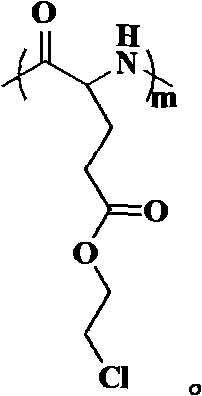

Chloroethyl alcohol functional poly (L-glutamic acid) homopolymer and random copolymer and preparation method and application thereof

A technology of random copolymer and glutamic acid, which is applied in the field of chlorohydrin functionalized poly(L-glutamic acid) homopolymerization and random copolymer and its preparation method and application field, can solve the problem of non-biodegradable and difficult preparation process Control, limit and other issues, to achieve the effect of non-toxic side effects, good biocompatibility and degradability, and improved intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: Preparation of different molecular weight poly(γ-2-chloroethyl-L-glutamate)

[0032] Weigh 3 parts of 2.356g (0.01mol) of γ-2-chloroethyl-L-glutamate-N-internal carboxylic acid anhydride monomer respectively, add them to 3 dry reaction flasks, add 5mL of anhydrous N,N-Dimethylformamide dissolves the monomer. Add 0.00033 mol, 0.00020 mol and 0.00014 mol of n-hexylamine under stirring, and then continue to react the solution at 25°C for 72 hours. Dry under vacuum for 24 hours to obtain three kinds of poly(γ-2-chloroethyl-L-glutamate) with different molecular weights. The obtained products are shown in Table 1.

[0033] Table 1 Preparation of poly(γ-2-chloroethyl-L-glutamate) with different molecular weights

[0034] experiment number

[0035] In the above table, A / I is the molar ratio of γ-2-chloroethyl-L-glutamate-N-internal carboxylic anhydride to n-hexylamine; Mn is poly(γ-2-chloroethyl-L- Glutamate) number average molecular weight, by 1 H ...

Embodiment 2

[0036] Embodiment 2: the preparation of poly(gamma-2-chloroethyl-L-glutamate)

[0037] Weigh 2.356g (0.01mol) of γ-2-chloroethyl-L-glutamate-N-internal carboxylic acid anhydride monomer into a dry reaction flask, add 5mL of anhydrous N,N-dimethylformaldehyde Amides dissolve the monomers. Add 0.00010 mol of hexamethylenediamine under stirring, and then continue to react the solution at 25°C for 72h. After the reaction, the reaction system is settled with 50mL ether, filtered, washed with ether three times, and then vacuum-dried at 25°C for 24h. Poly(γ-2-chloroethyl-L-glutamate) was obtained with a reaction yield of 75.3%.

Embodiment 3

[0038] Embodiment 3: the preparation of poly(gamma-2-chloroethyl-L-glutamate)

[0039] Weigh 2.356g (0.01mol) of γ-2-chloroethyl-L-glutamate-N-internal carboxylic acid anhydride monomer into a dry reaction flask, add 50mL of anhydrous 1,4-dioxane Dissolve the monomer. Add 0.00010 mol of n-hexylamine under stirring, and then continue to react the solution at 25°C for 72h. After the reaction, the reaction system is settled with 500mL ether, filtered, washed with ether three times, and vacuum-dried at 25°C for 24h to obtain Poly(γ-2-chloroethyl-L-glutamate), the reaction yield was 76.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com